Our friends at Friction Facts are at it again, this time with a new test fixture to measure the friction generated by bottom brackets. In this round, Friction Facts tested 35 different models from twelve manufacturers: C-Bear, CeramicSpeed, Chris King, Enduro/Wheels Manufacturing, F1 Ceramic, FSA, Gold Race, Hawk Racing, Hope, KCNC, Shimano, and SRAM. Also compared were other variables such as bearing materials, seals and lubricants, and even fitment type. The results might not be quite what you think.

Lesson #1: Ceramic is not always better than steel

Ceramic bearing-equipped bottom brackets – or hybrid ceramics, to be more precise – are generally much more expensive than their stainless steel cartridge-equipped brethren. Manufacturers claim that they're not only faster by virtue of generating less friction, but in some cases, also more durable.

Friction Facts' new jig isn't equipped to test durability but in terms of drag, the ceramic myth has been thoroughly debunked.

"Bottom Bracket efficiency is predominantly based on the design and the quality of materials used, not the material itself," Friction Facts principal Jason Smith wrote in his latest report.

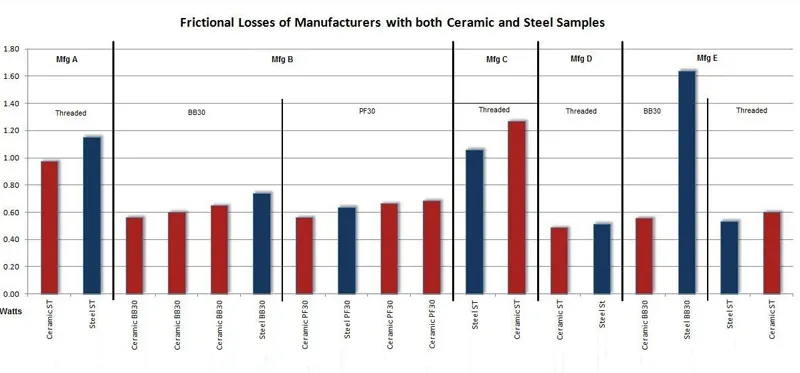

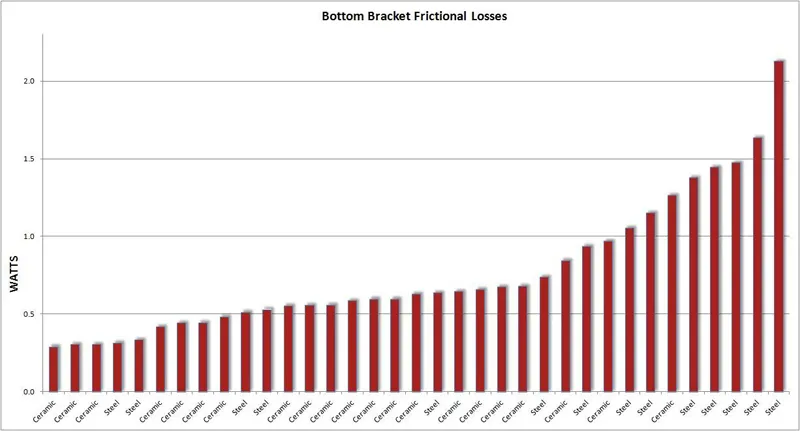

According to Smith's data, the difference in drag between the top steel model (0.32W) and the best ceramic model (0.29W) was just 0.03W – virtually nothing. Moreover, out of five manufacturers with comparable steel and hybrid ceramic models, three actually posted lower friction values for the steel models than for the otherwise identical ceramic ones.

Despite what the marketing tells you, bottom brackets with hybrid ceramic bearings don't always spin with less drag than ones with stainless steel bearings

Lesson #2: Small variances between individual models but additive effects can be big

Save for one outlier built with roller bearings instead of ball bearings, the spread between the remaining 34 models is quite small. The best sample generates just 0.29W of drag while the worst one records a still-good 1.64W – with just 1.35W in total when comparing average values. In addition, the average drag for all of the bottom brackets tested is just 0.77W.

In other words, bottom brackets do different significantly drag-wise in terms of percentages but as far as actual watts are concerned, we're talking relatively small numbers here that most general cyclists aren't likely to notice. For riders that are much more concerned with power losses, however – such as time trial racers and number crunchers in general – Smith suggests that there are easy gains to be made as long as you're willing to spend a little money.

Moreover, Friction Facts says the brands posting the best drag figures for the bottom bracket test also happen to offer some of the most efficient derailleur pulleys. Coupled with drag data Friction Facts has recorded from other drivetrain variables such as chains and chain lubes, riders could get as much as an 11.29W swing just by swapping out a few key components, depending on their starting point – a huge value for fit riders and racers that are already nearing their peak fitness.

There isn't a huge amount of difference between the bottom brackets tested but for those that are seeking every last second, the additive effects can be significant once you start incorporating other drivetrain components

Lesson #3: Drag and cost aren't always related

Bargain hunters will be happy to know that you don't always get what you pay for, at least when it comes to drag. For both the SRAM and Shimano bottom brackets tested, Friction Facts found that the lower-end units were actually more efficient than the more expensive options. The implication, however, is that the higher-end units are also better sealed than their more affordable counterparts - something that should also figure into your buying decisions.

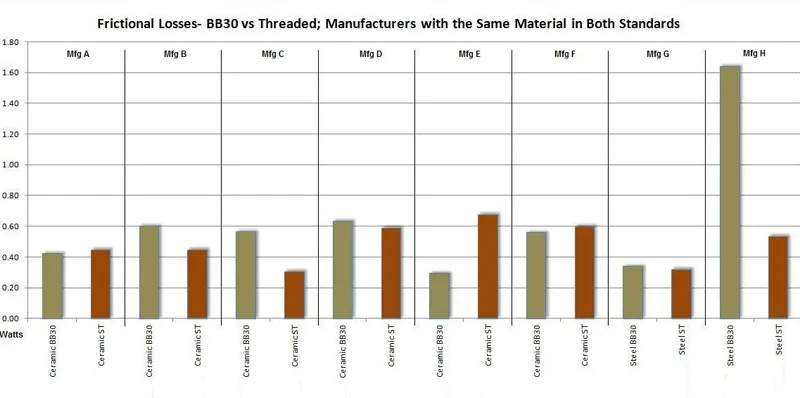

Lesson #4: One fitment standard isn't necessarily better than another

Adherents to oversized bottom bracket standards such as BB30, PF30, BBright, and BB386 EVO love to go on about how their systems are better than conventional 24mm bottom bracket spindles – but according to Friction Facts' data, what they can't rightfully claim is that they're more efficient, at least in terms of bearing drag.

(Click here to read BikeRadar’s complete guide to bottom brackets.)

According to Friction Facts' latest report: "No statistically significant difference exists showing a general advantage or disadvantage of a standard type under similar loading conditions. It appears the frictional losses are heavily dependent on the manufacturer, quality, and design of the bottom bracket, not the standard itself."

That being said, Friction Facts' testing didn't take into account other factors such as component weight or the torsional stiffness of the crank spindles under load.

Does a BB30 bottom bracket spin with less friction than a standard threaded one, or vice versa? Neither, actually

Lesson #5: Seals and grease matter

While most of the attention for bearing components is paid to materials and ABEC ratings, Friction Facts says the seals and lubricants used actually have an even greater affect on total drag. C-Bear, for example, offers the exact same bottom bracket for both road and mountain bike applications, varying only in the robustness of the seals and the viscosity and amount of the grease that fills the cartridge.

According to Friction Facts, the road variant generates just 0.31W of drag while the presumably more durable mountain bike one records a figure that's more than twice as high at 0.85W.

Lesson #6: Drag isn't everything

Keep in mind that all of Friction Facts' bottom bracket testing pertains only to drag and doesn't factor in other metrics such as durability, weight, or weather-sealing – all of which should also be factored into your purchasing decisions.

One of the more extreme cases is Gold Race's BB30 ceramic bearings – the outright winner of the test – which posts extremely low friction numbers but doesn't use contact seals or grease. In fact, you can see right through them. In fairness, Gold Race only recommends these particular bearings for indoor/track use, but it isn't hard to see how a friction-obsessed buyer could easily be lead astray.

These Gold Race BB30 bearings spin with ridiculously little friction - but you wouldn't want to use them on the road or trail

Finally, drag obviously isn't everything. Buyers who aren't as concerned with efficiency may very well want one of the models that posts the highest friction numbers as they're also likely to use the most robust seals and lubricants.

Ultimately, consumers should consider their priorities when it comes to purchasing a new bottom bracket and evaluate different models accordingly. Thanks to Friction Facts, we now have some better data to help us make an informed decision.

While we're able to share general trends and the key findings of this study, we can't divulge specific data. For the results of each bottom bracket model and more information on specific testing methodologies, visit the Friction Facts web site to purchase the full report.