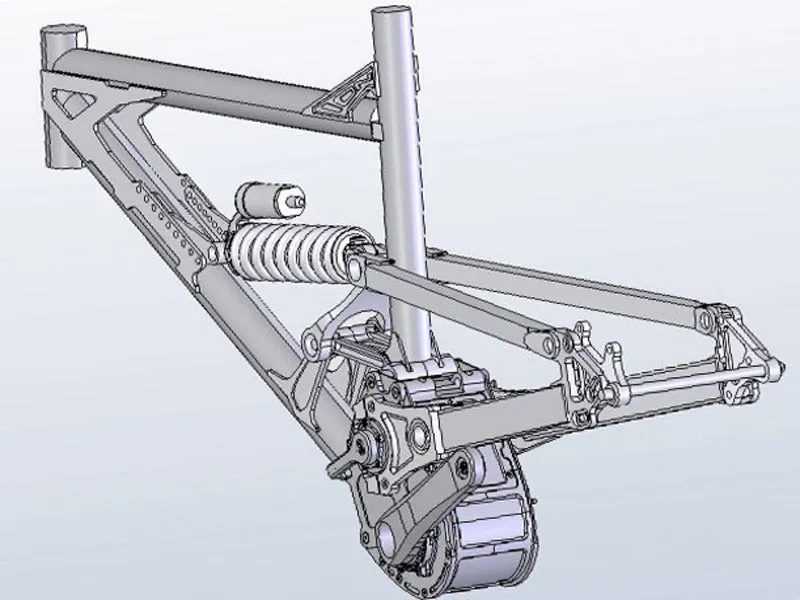

KarlHeinz Nicolai is known for three things in the bike world: his no compromise mountain bikes, his pefectionism, and his G-Boxx. What is a G-Boxx? The majority of bikes use a drivetrain system based around externally mounted derailleurs and gearing cogs. G-Boxx bicycles, on the other hand, contain a transmission mounted inside the main frame – with the bottom bracket housing replaced by an integrated transmission.

Similar to drivetrain mechanisms, a chain or belt drive system is used to provide power to the rear wheel. But in the G-Boxx system, the chain (or belt drive) does not have any shifting duties.

KarlHeinz and his team feel that their G-Boxx system has the advantage of eliminating many common problems associated with a derailleur based system. Since the drivetrain components of typical bicycles are all exposed and attached as separate parts to the frame, they are exposed to the elements (especially in the UK) e.g. dirt, water, grit, sand. This causes the deterioration of the moving parts over time, which in turn means that you can spend more time in yours or the local bike shop’s workshop, than riding your bike. In addition, debris and rocks can cause considerable damage to the drivetrain, making the entire system inoperable, until you get out your credit card!

According to KarlHeinz, the G-Boxx system provides a unique, simple and clean solution to all of these problems by enclosing all drivetrain based components inside an encapsulated system. This allows the efficiency of the G-Boxx to remain constant and provide the rider with continuous forward momentum.

Bike Radar:Is G-Boxx the future? If so, could it be used for all applications?

Yes, the G-BOXX is able to beat derailleurs and hubgear shifting in DH performance now. For All-mountain bikes, city bikes and other recreational bicycles we need another 1-2 years to come up with a wider ratio range gearbox. The latest incarnation, the G-Boxx 2, weighs in at between 300-500 grams, and therefore would be an unacceptable weight increase on superlight XC mountain bikes and road racing bikes at present. For this reason, we also still build bikes with standard derailleur based drivetrains.

How simple will G-Boxx be to fix?

Our G-BOXX-2 is very simple to build for people with a basic awareness of assembling and fixing a bicycle. Our G -Boxx website has detailed instructions on assembly and maintenance. In addition, you can contact us directly if you need more help.

Tell us about your background. Was it in engineering, racing or graphic design?

I think I have a little of these 3 skills. In the late 1980s I was racing in motocross and enduro motorbike races, and due to a lack of money, I had to rebuild the suspensions and motorcycle frames myself at home. I always sketched my dream bikes on paper, too. In order to extend my scientific background, I went to University in 1988 to study mechanical engineering.

You’re renowned for making the fattest, most beautiful welds on your Nicolai frames, how long does each frame take to build? And, are you a perfectionist?

It is simple: we get up early every day to manufacture the best bikes. Our products of today (or this year) should be more perfect than yesterday. I buy my bread and butter every day from money I get from customers, so I think these customers deserve perfect quality.

Nicolai frames are renowned for beautiful design, faultless engineering and brute strength. Which is most important to you?

Just bring all of these 3 in a perfect balance, and you will have the perfect bike.

You work closely with Easton. How did this come about and why is Eastonthe best tubing in your opinion?

I have worked with them since 1995. In 1995, Easton was the only tubing factory around able to make the tubing for my Mongoose project. In those days you had no email ....so I picked up the phone and called them and they responded. For lightweight structures, they still produce great stuff. It is expensive, but it is worth it.

As a result, you work exclusively in aluminium. What do you make of the current trend for carbon?

With aluminium, we are able to manufacture lightweight frames with a 5 year warranty even in racing conditions, so why switch the material? Additionally, with aluminium we are still able to perfectly tailor the frame to the body of the rider.

A lot of your frames use the Horst Link rear suspension design. Why is this your favoured rear suspension design?

In 1991 I was working for a US-company called AMP research. At this time, I was actually involved in the development of the Horst link, so you can imagine why this is my favourite suspension system! For more information, please visit their website http://www.amp-research.com/prove/history.aspwhere you can see a detailed history of the work I was involved in.

Your bikes come in a fantastic range of colours. What is your favourite and why?

Tthat would have to be British Racing Green! It is such a calming colour. You can look at it for years and never get bored of it.

What’s the strangest request you’ve ever had for a custom build?

There was this guy from Russia who collects the most expensive land vehicles like tanks, sports cars, trucks and caterpillar machinery. Additionally he has chosen a Nicolai Nucleon ST G-Boxx bike.

And finally, Karl-Heinz, I’ve got to ask you - Did you play with Mechano when you were a kid?

Sure!! In Germany it is called "fischer technik."