Cyclo-cross racing's surge in popularity Stateside has brought with it an increasing use of tubular tires. Road racers have long touted sew-ups for their smoother ride, more predictable cornering and improved safety relative to most clinchers, but for 'cross racers, it's all about grip.

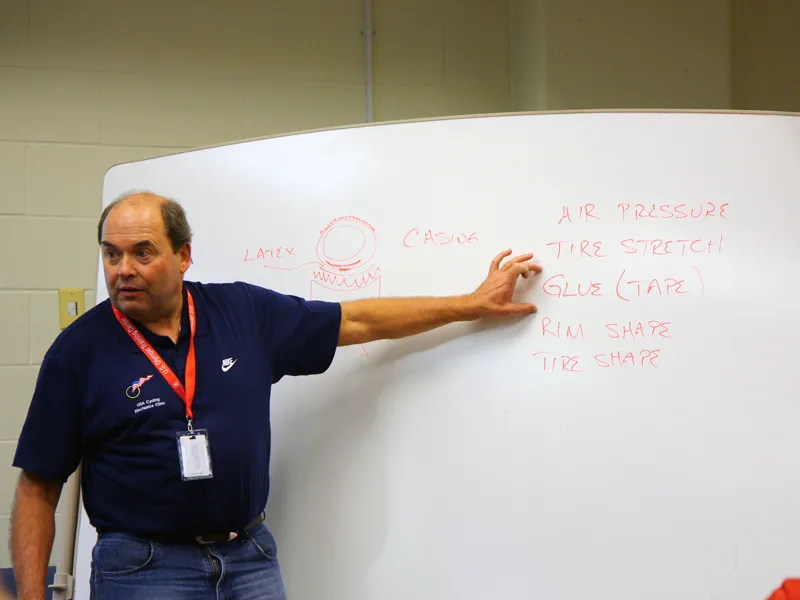

Tubular tires' generally more supple casings and the ability to run ultra-low pressures still offers an unparalleled advantage in most situations, but that drastic pressure difference also has major implications for how they're held onto the rim, as tubular expert Chip Howat explained to us.

Howat has a long history in researching tubular tire gluing methods and performance, first as an unofficial consultant to the United States Olympic team at the 1984 Games and now as the unofficial 'guru of glue' for USA Cycling's annual race mechanics clinic.

"I first struck up a relationship with Calvin Jones at Barnett's Bicycle Institute [Jones is now with Park Tool]," Howat said. "He asked about tubular gluing because he'd noticed at the LA Olympics that the tires were tending to migrate on the rim as the glue failed due to the high temperatures. He had some questions about adhesive performance, cohesive performance, and that piqued my interest.

"I started working with him to develop a protocol to test tubular glues and tire and rim combinations back in '92 or '91. Then he went on to do other things and I just kept gluing. At one point Discovery Channel contacted us to look at carbon fiber rims and supplied us with rims, which got us going on the carbon fiber gluing and we just kept going."

Howat now funds the studies himself but began while a professor at the University of Kansas with "unrestricted funds from a variety of donors". USA Cycling provided stock of old and obsolete rims. Mavic also supplied boxes of rims and he tapped his graduate and undergraduate students as labor so the only costs were tires. These days, though, it's just a hobby.

Among the lessons learned:

- Vittoria's Mastik One glue provides the strongest overall bond

- Continental glue is a close second – though the difference is greater at elevated temperatures – but cures faster so it's a better choice when time is an issue

- While popular, 3M Fast Tack bonds only 60 percent as well as Mastik One at room temperature and it's also less temperature stable

- Clement, Wolber and Panaracer glues came in at the back of the pack in terms of adhesive strength

- Tufo's dual-sided tape is convenient to use but doesn't work well – the adhesive strength isn't very good plus it doesn't bond the tire at the edges

- Cure time is key – bond strength can climb more than 30 percent higher after 24 hours than just one hour after tire installation, and it continues to improve marginally afterward

Howat says there are three main factors that work together to keep a tubular tire on a rim: the diameter of the tire and rim relative to each other, air pressure, and the adhesive bond between the two. Most rims are designed with road-sized tires in mind; this means the interference fit isn't as good with 'cross tires, which are generally much bigger and more pliable.

'Cross tires are also run with much lower air pressure. Depending on the conditions, they're often subjected to high lateral load spikes, too. If the tires aren't glued properly, it’s a recipe for disastery, since the adhesion is just about the only thing left keeping them from shedding off of the rim.

We published a detailed gluing procedure last year that, coincidentally, is nearly identical to the well-proven method that Howat recommends. It's rigorous, for sure, and perhaps borderline obsessive, but the result is generally a secure and safe bond that won't let go on race day.

It's all about the mating surfaces

One of the key tenets of Howat's gluing procedure is building up a surface of adhesive that fills in whatever discrepancies may exist between the cross-section of the rim and the tire. "The most important mating surface is at the edge," he told BikeRadar. "So as we move out from the centerline of the rim, we want really good adhesion – the thicker that edge is, the better.

"What makes the adhesion or the performance deteriorate [in terms of the rim-tire interface] is how prominent that seam is in the tubular tire. What I like is a large gluing surface around the edge with a deep channel that allows the seam to nestle into the rim. The seam doesn't even have to come into contact with the rim. One of the least effective places to glue is the center of the rim and so consequently, if that seam is just nestled into a trough and not glued, that doesn't bother me. But I really like the wide edges."

This thick layer of adhesive is essential because a 'cross tubular measuring 32-34mm across is being mounted on a rim intended for a road tire that's just 21-23mm wide. "If you have a 21mm tire and look at the cross-section, it has a certain radius that meets up against the effective radius of the rim gluing surface cross-section," said Howat. "The 'cross tire radius is larger than the road tire radius so the tire touches at the edges of the rim and then doesn't touch at all on the gluing surface. What you're effectively doing is decreasing the niceness of the two mating surfaces so you're going to have to build up the mating surface on the rim in some way to get more adhesion on the 'cross tire joint."

Howat's (and our) procedure advocates multiple thin coats of glue on the rim with roughly a day in between each application. The aim is to build up a thick bed of contact that will fill in the gaps between the tire and rim but still fully cure for a proper bond. While Howat doesn't do this himself, he says applying a strip of tubular tape down the center of the rim bed can also effectively increase the radius of the rim bed for a closer fit between the two mating surfaces.

"The challenge with a larger tire is to make sure you build up this good mating surface so that the adhesive can do its job," he said. "But just like on the road, the most important joint is out on the edge." Howat said that ideally, every tubular rim would have a deep channel down its center to accommodate even bulky seams and rims would be rated for different diameter tires, too.

The hidden pitfalls of power washing

One associated burden of 'cross racing is frequent bike washing, often with highly pressurized water. In addition to the potential havoc this can wreak on bearings and untreated cotton sidewalls, Howat cautions that pressure washing can also quietly degrade tire adhesion, though not in the way some may think.

"Cured glue is not water-soluble but the base tape is permeable and so what happens is that the water gets into the base tape and disrupts the adhesion there," Howat said. "That's why I tell people to glue up past the base tape to act as a seal, particularly for base tapes that don't have any latex or anything on them."

Even with a properly glued tubular, it's still a good idea to periodically check the bond performance of your 'cross tire to ensure the joint hasn't started to fail – especially if the season is especially wet and muddy.

On the pros and cons of tubulars in general

Four-day installation times, messy glue, high costs, limitations on swapping tread patterns on race day: with all of these negatives, why bother? Outright performance is one thing – something even the best clinchers and tubeless setups haven't been able to match to date – but Howat is insistent that tubulars don't pose nearly the challenge many might think they do.

"Tubular tires went through a period when it seemed like they were getting archaic but it's still the state of the art," he said. "Yes, it's a hassle at first but you learn to do things in advance – you glue a batch of tubular tires and store the ones you're not using so you don't have to go through that procedure again. Yes, you have to put a coat of glue on but that's relatively easy once you get used to it and you don't have to do it everyday to stay skilled at the art. So I don't think it's as much of a hassle as the stereotype of tubular tires seems to be."

Furthermore, Howat argues that tubular tires can be more durable than clinchers, not less. "First of all, there are no pinch flats," he said. "You obviously pay for what you get, but for example, this year I have about 3,300 miles on the road and my wife has about 4,000 miles and we've had two flats the entire year. I don't consider that all that bad, and both of those were glass cuts so a clincher wouldn't hold up to that, either."

Howat says he's also been impressed with the performance of various latex-based sealants – both as a preventative measure and also to repair a puncture after the fact. "When I mount up a new tubular, I put in a couple ounces of sealant," he said. "I found that with the exception of intense glass cuts or something pulling the valve stem off, it'll seal and you can get hundreds of miles more out of the tire, where before you'd have to pull the tube, patch it and seam it back up or throw away the tire. And of course, you can ride tubulars flat and still make it home. I know racers don't [use it] but I think they're more tuned to their bikes and the sensitivity of their bikes than most riders are."

DIY or pay-to-play?

"Our procedure is intended to do the best job possible – not an adequate job," said Howat. "Following our procedure, consumers should have confidence that the tire is going to stay on the rim." However, he acknowledges that regardless of his opinion, many riders simply won't want to deal with mounting tubulars themselves and will prefer to have a qualified shop do the job – but how does one find a qualified shop?

"It's almost like you're interviewing a surgeon," he said. "If you're going to have surgery, you're not just going to pull someone off the street; you're going to find out if they've done this surgery before and if you don't like the answers, you're not going to put yourself at risk.

He suggests asking the shop about the minimum turnaround time for mounting a tire – a 'while you wait' service is probably a red flag, for example – and even the asking price can be a good indicator. While not hugely time consuming, proper tubular gluing isn't a quick process, so expect a shop to charge accordingly. If it sounds too cheap to be true, it probably is.