A disc brake rotor is a component that mounts to the hub of a bicycle wheel and provides the braking surface in a disc brake system.

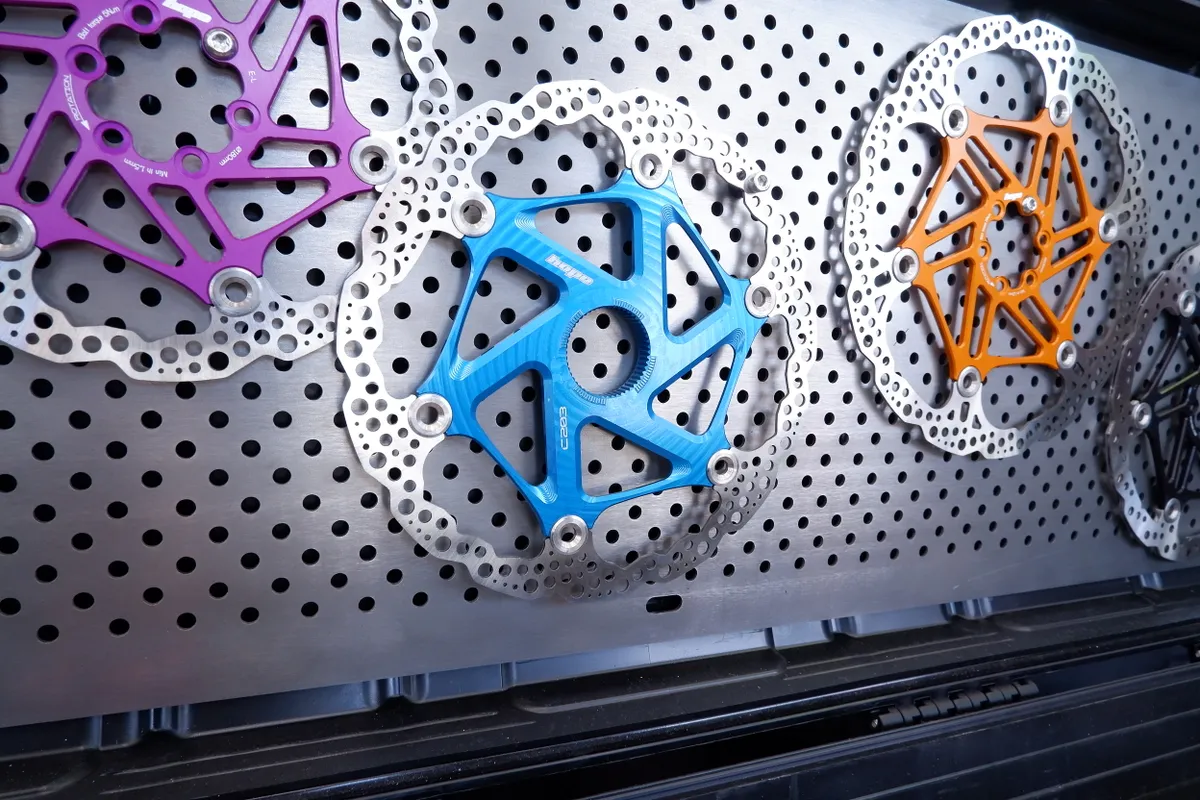

Disc brake rotors come in a wide variety of sizes to suit different riding disciplines and terrain.

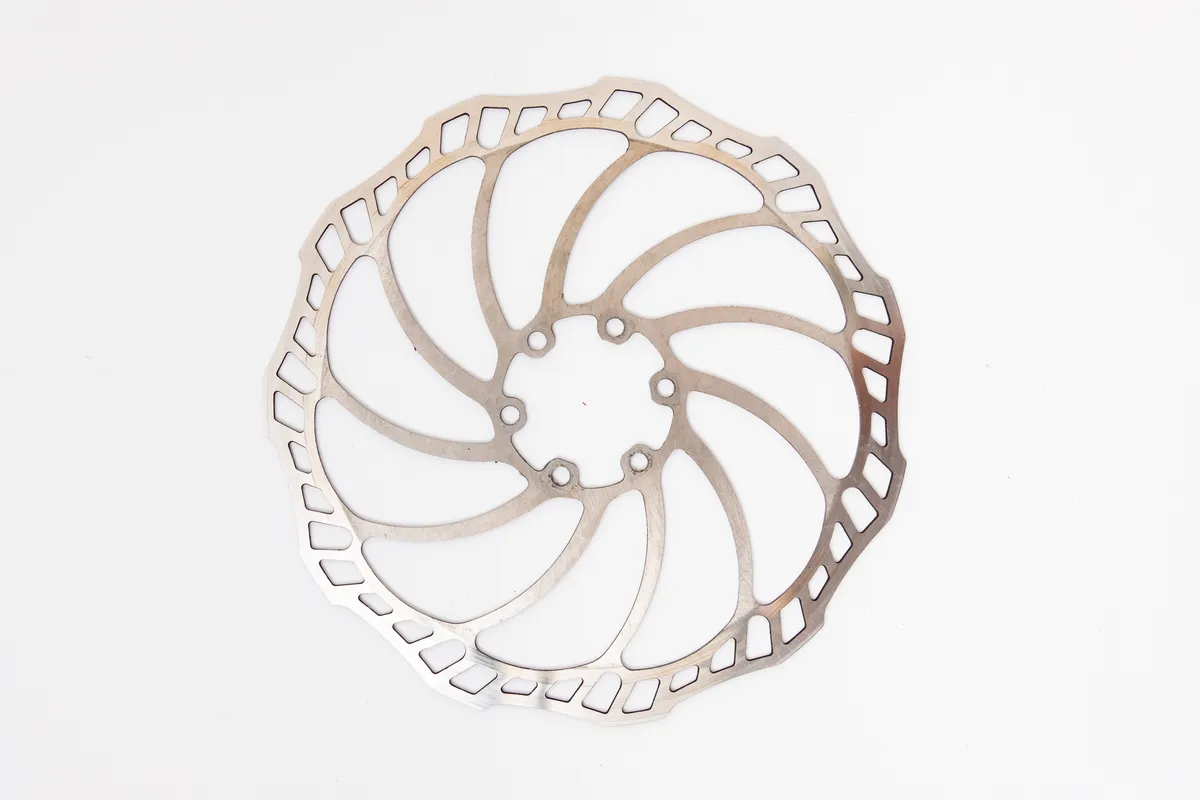

The simplest disc brake rotor will be stamped from a sheet of stainless steel. More expensive rotors use more complex constructions to improve braking performance and reduce weight.

Though other standards have existed, modern rotors mount via one of two standards – 6-bolt or Center Lock.

In this article, we outline everything you need to know about disc brake rotors, including what to look for if you’re shopping for new rotors for your bike.

What are disc brake rotors?

The disc brake rotor is the metal disc attached to the hub of the wheel. The rotor is the braking surface for the brake pads and caliper.

They are available in different sizes and designs to suit different applications.

Some disc rotors are designed to provide as much power and heat dissipation as possible, whereas others prioritise low weight over all-out braking power.

Disc brake rotor sizes explained

The job of a disc brake rotor is to slow the rolling momentum of the wheel, using friction created by the brake pads and caliper squeezing the rotor.

In doing so, heat is generated. The bigger the disc rotor, the more heat can be absorbed before it overheats and braking power starts to drop (or fade, to use the correct term).

Generally speaking, the bigger the rotor, the better the braking performance will be.

However, not all bikes and riders need maximum braking power. In many cases, it’s about finding the balance between power, brake feel and weight.

As a general rule, road and cyclocross rotors sit in the 140 to 160mm range, striking a balance between necessary braking power and low weight.

Modern mountain bike brakes often come specced with rotors ranging from 180 to 220mm.

Many mountain bikes will have a larger front rotor, paired with a smaller rear rotor (200mm front and 180mm rear, for example).

However, it’s becoming more and more common to see large rotors (200mm and up) being specced front and rear on enduro or downhill mountain bikes. Electric bikes may also use larger rotors to compensate for additional weight.

| 140mm | 160mm | 180mm | 200mm+ | |

|---|---|---|---|---|

| Road bikes | X | X | ||

| Gravel bikes | X | X | ||

| XC bikes | X | X | ||

| Downcountry bikes | X | X | ||

| Trail bikes | X | X | X | |

| Electric bikes | X | X | X | |

| Enduro bikes | X | X | ||

| Downhill bikes | X |

Disc brake rotor design and materials explained

Most rotors are made from high-quality stainless steel, which provides a durable braking surface suitable for use in all conditions.

The braking surface is designed with cut-outs, as well as recessed slots. These enable water, mud and other road or trail debris to clear out from between the pad and the rotor.

Strategically placed holes also help to shed weight without impacting performance.

One key design aspect is the rotor's ability to dissipate heat. This is achieved in a number of ways.

Some rotors feature heat-dissipating paint applied to the ‘spokes’, which connect the braking surface to the central portion of the disc.

Another method, seen in SRAM’s latest MTB rotors, is to increase the thickness of the rotor itself.

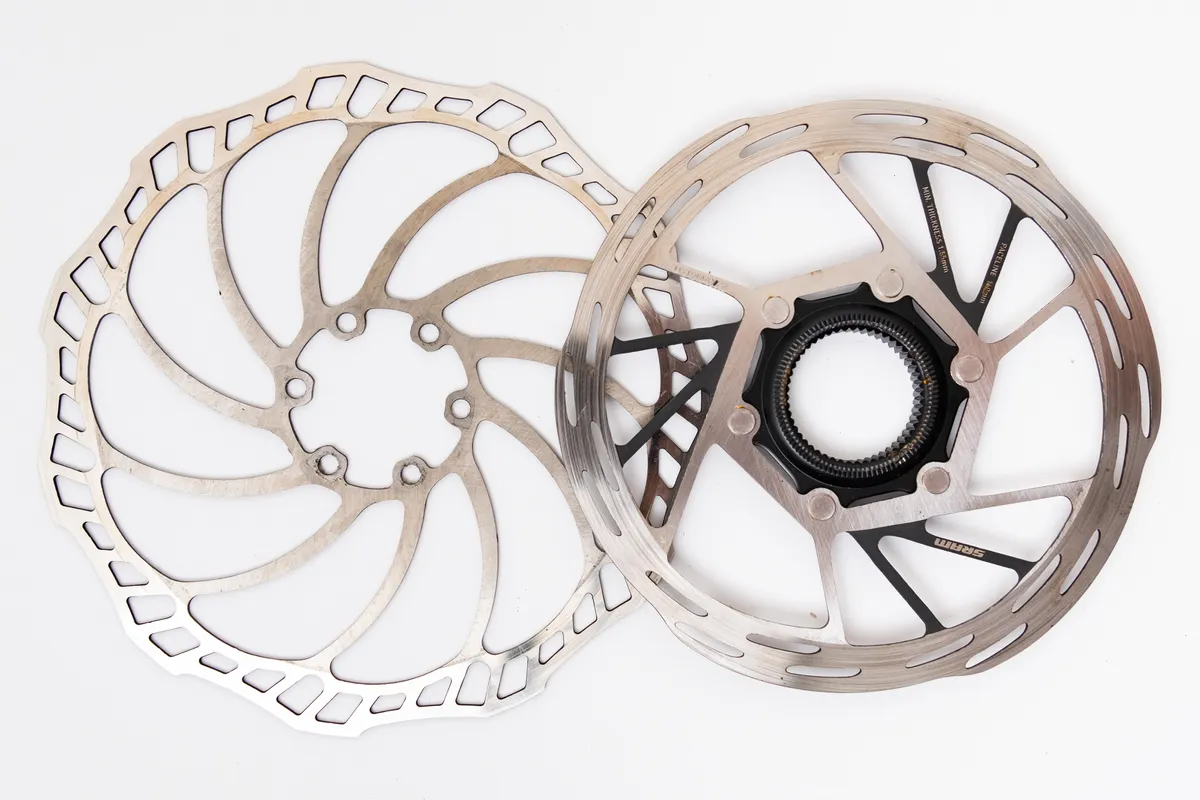

Some disc brake rotors use a floating design borrowed from motorcycles, where the stainless steel braking surface is attached to an aluminium carrier by rivets.

This design is claimed to offer improved heat dissipation and resistance to warping over standard steel rotors, while also being a little lighter.

Shimano IceTech rotors sandwich a finned alloy layer between the two stainless steel braking surfaces to improve heat dissipation.

Disc brake rotor mounting standards – Center Lock vs 6-bolt

In order for a disc brake to function properly, the mounting interface attaching the rotor to the hub has to be stiff and strong. Two mounting standards are used.

The first and most common is the six-bolt standard.

Here, the disc rotor is attached to the hub via six Torx bolts, laid out in a circle around the axle.

The six-bolt design is light, strong and simple and, while somewhat tedious, it doesn’t require any specialist tools to install or remove a rotor.

The second standard is called Center Lock. Here, the rotor fits onto a splined interface on the hub and is secured by a threaded ring that screws onto the hub, holding the rotor in place on the splines.

While removal and installation are slightly simpler, a Shimano HyperGlide-style cassette tool or bottom bracket tool is required.

Compatible pads

There are three main types of disc brake pads available – organic, sintered and semi-metallic. Each pad material has its own properties.

You can run any of the available pad compounds with any brake rotor, provided you take the time to properly bed in the new pads.

When to replace your disc brake rotors

Just like brake pads, rotors are consumable parts. Braking erodes material from the rotor and, in time, they need to be replaced.

Thickness is a good indicator of when it’s time to replace your rotors.

Shimano recommends its rotors, which are 1.8mm thick out of the box, should be replaced when they measure 1.5mm or thinner.

SRAM also recommends replacing your rotors when their wear exceeds 0.3mm, or when their thickness is less than the minimum value stated on the rotor.

How do I know which disc brake rotors I need?

When in the market for new disc brake rotors, there are a few things to keep in mind.

First of all, it makes sense to stick to the same brand as your existing brakes, unless you’re looking specifically for aftermarket options.

Next, you have to take into consideration the mounting standard you have on your current wheels – this will either be six-bolt or Center Lock.

The final decision is the rotor size.

First, consult the maximum rotor size your frame and fork are rated for. Then, decide if you need more power. If you feel your brakes are fading frequently and you wish you could slow down easier, we recommend sizing up to a larger rotor (if possible).

It’s important to note you may also need to buy new brake-mount spacers to accommodate the larger rotor.