Bikes made from wood are nothing new, and there’s no shortage of craftsmen out there making bikes with trees.

- Here's a stylish wooden bike you can build from scratch in a weekend

- Best mudguards: a buyer's guide — including wooden mudguards

However, a small outfit out from Western Australia is combining wood and carbon fiber to create boutique performance-oriented frames — yes, you read that right, wooden race bikes.

Hayden Francis, HTech's frame builder told BikeRadar: “Wood is a naturally stiff and strong material, one of the strongest found in nature. Today, with modern woodworking machines and extremely strong and durable adhesives, wooden bike frames can be made as strong and stiff as carbon frames with more comfort than a steel frame.”

Problem solving

The trouble with wood, however, is under forces on a specific axis, it splits up the grain, a problem many wood bike makers haven’t efficiently been able to solve. However, it seems Hayden has solved the problem and the answer was staring him in the face the whole time.

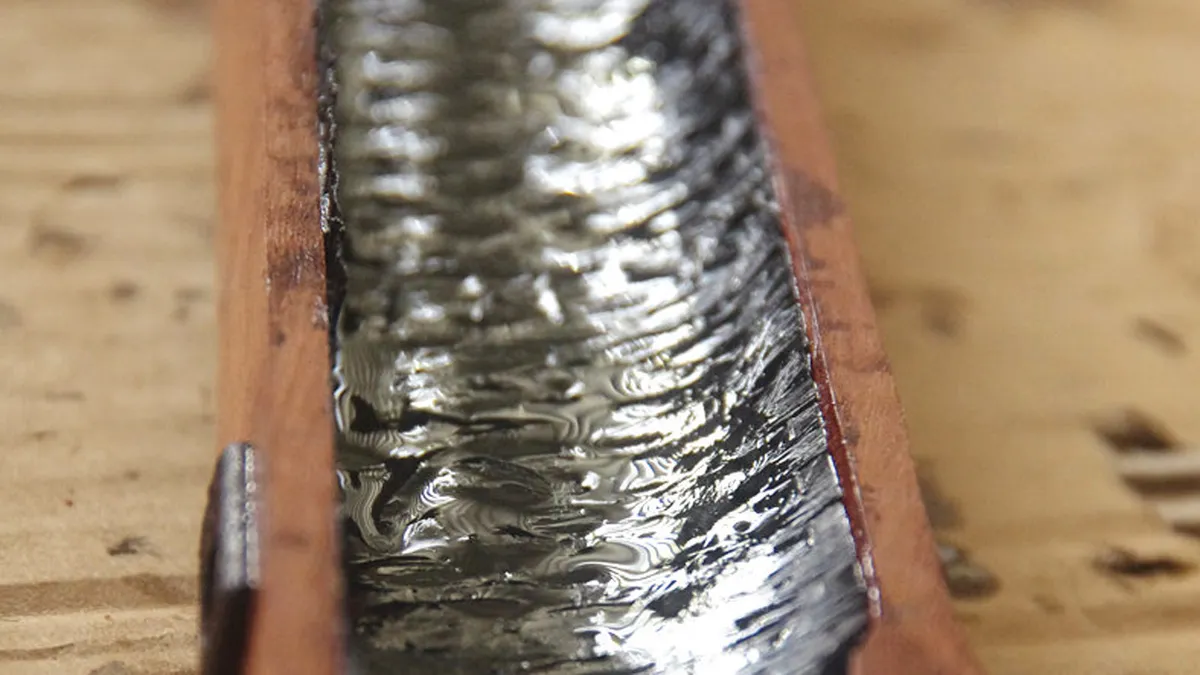

Hayden's dad Jason also works for the company and says that “It seemed logical, you’ve got a carbon frame so why can't you blend carbon into a wood frame." He tells us that "We’ve experienced them [the frames] splitting up the grain of the wood, but we use unidirectional carbon across the grain to provide additional strength. So you still get the grain running long ways and the carbon is used to combat torsional flex, which is what causes the wood to split.”

This process is called Selective Carbon Reinforcement (SCR) and sees each tube lined with carbon sheets, which is utilized in both the Aeriform and Aeriform Disc frames. Jason tells us because of wood's naturally cellulose structure with fibers varying in density — seen as light and dark rings — they vibrate at different frequencies and effectively absorb road buzz and impacts. While the carbon does stiffen things up a bit, HTech only uses what's needed so that it doesn't drastically change the ride quality.

Beyond the tube reinforcement, the PF86 bottom bracket shell is also made from carbon as is the headtube’s inner sleeve, which is bonded to machined aluminum headset cups.

Tuned hardwood

All of HTech’s bikes are made of Jarrah, Marri, and Blackbutt hardwoods, which are unique to Australia. While they all differ in strength, stiffness and modulus, Jason tells us that the building process sees wall thickness varied slightly to keep the ride quality consistent between the three.

“With the Marri not quite having the same stiffness as the Jarrah, [Hayden] makes it thicker to accommodate for the difference. He's trying to tune the bikes to have the same ride. Really the difference is some people like to have a light coloured wood and some people like a darker one.”

Each of the frames are shaped by hand and every frame is uniquely tuned to its rider based on their weight. Boards of the selected type of wood are bonded together and the tubes are made in two pieces which are then shaped inside and out before they’re bonded together using industrial epoxies.

While wood bikes are always going to weigh more than their carbon cousins, Jason tells us that the Marrie frame (pictured above) weighs 1,402g and the complete builds of the Aeriform Disc with an Ultegra group are claimed to weigh just 9.7kg — about the same as a low-end carbon bike like the Reid Vantage.

The finished product is so well polished inside and out that at first glance you’d guess HTech's bikes were crafted by a master carpenter with decades of experience on the tools. However, Hayden is only 19 years old.

“He’s done a lot of carpentry and he’s very good at it. He’s into cycling and one of the projects while he was at school was a free project. [Hayden] said to his teacher 'I think I’d like to make a wooden bike' and of course his teacher said 'you’ve got be kidding', and the challenge was on,” Jason explains.

“It’s all his own research and putting it into practice. To say he’s done thousands of hours of research would be conservative,” he continues.

With this, the frames have the hallmarks of contemporary race bikes like asymmetric chainstays, internal cable routing, disc brakes and of course the clever use of materials.

Nonetheless, Hayden is producing beautiful bikes and appears to have cleverly solved a problem that has plagued the genre. HTech is currently taking orders for frames at an introductory rate of AU$3,000 for the Aeriform and AU$3,200 for the Aeriform Disc.