This fall Ultralite Sports will begin selling two impressively light pedals based on a spring-loaded, sliding-barrel system.

The cleat's engagement point resembles a thick letter C, and you snap it onto the spindle by sliding the pedal’s outer barrel inwards, then pushing down. Clipping out requires the same inwards push, then a direct lift up. Pivoting your foot with the heel out, as you would on a standard pedal, does not release the cleat.

The $450/£279 Cirrus Ti model weighs 124g for the pair of pedals (72g) and the pair of cleats (40g) and screws (12g).

The $325/£200 Nimbus STL uses the same design but with a steel spindle instead of the Cirrus Ti’ titanium option. It weighs 158g a pair.

Ultralite Sports pedals are made in Colorado. Masters racer Bill Emerson and product design engineer Neal Beidleman (of "Into Thin Air" fame as an alpinist) are behind the company.

Emerson most recently used Speedplay pedals for about 20 years. Many years ago, however, he rode with AeroLite pedals, which have a somewhat similar spindle-as-pedal design. “But for those, you had to screw holes into your shoe,” he said. “They were interesting.” (AeroLite now has other mounting options.)

Reducing rotational weight was a main driver behind the Ultralite concept, Emerson said.

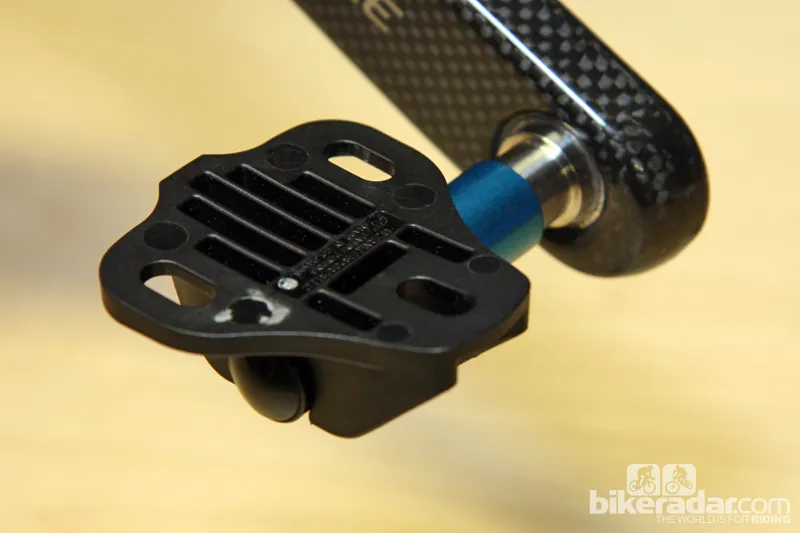

The entire system (including bolts, not shown) weighs 124g

At 124g/pair, the Cirrus Ti pedals are lighter than Shimano Dura-Ace at 325g/pair or even Speedplay’s Zero Nanograms at 217g/pair. But there are compromises.

Price aside, the primary obstacle for Ultralite’s pedals gaining acceptance is the markedly different clip-in/out method. While Beidleman and Emerson say the learning curve is short, we found ourselves grabbing onto cars at traffic intersections when we were unable to pop out at stoplights. The company has not tested disengagement in the event of a crash, and we were not inclined to do so either.

Other drawbacks from the cleat design follow — walking on the narrow cleat feels much like walking on an ice skate. And while Beidleman says rubber bumpers to the thermoplastic cleat are in the works, the plastic showed wear from walking after just one use. As with Speedplays, getting mud or grit into the cleat can affect engagement.

A trio of concentric bores in the cleat allows for snug engagement on the pedal. The clearances are tight but the mating surfaces shouldn’t be subjected to wear if everything is working properly

Another notable point: the pedals are absolutely unrideable in street shoes, as the outer barrel rolls freely on the inner barrel.

But the Ultralite team are hoping that the reduction in weight will trump these concerns. “A pound off your feet, in rotating weight, is worth a lot,” Emerson said.

For now, the cleats are fixed, but a /-2-degree float cleat is in the works. To allow riding in street shoes, a wide, flat, clip-on platform is in the works, too, they say.

The washers at far right can be used to slightly adjust pedal-stance width (Q-factor), while preload for the retention system can be adjusted by adding washers behind the spring

Array