Yorkshireman Chris Hadaway is a floor-fitter by trade who had a bright idea: why not use the latest super-powerful LEDs to make bike lights that are better than those from the big manufacturers, and cheaper to boot?

The result is his range of Troutelights, which he designs and builds in his garage in Silsden, below the Yorkshire Dales, and just down the road from two other pioneering British cycling manufacturers, Hope Technology and Orange Mountain Bikes.

Ruth Brooker travelled up on a bracing February afternoon to meet him and check out the lights for herself.

How the project began

When I arrive, Chris is pottering in his garage/workshop that looks out across the hills. He’s surrounded by well-used machinery, trays of light cases and dozens of tools that are hanging up neatly. A “compulsive tinkerer who just likes making things”, he had built a Land Rover from scratch before starting the light project.

When the first LEDs that were bright enough for off-road riding arrived six years ago he was reading a post on a cycling forum by a guy who had made his own bike light and thought, "I could do that".

“I picked up the idea as a hobby," he says. "I hoped I could make a better light than the manufacturers, for less money."

Chris kept abreast of developments in the LED market by reading “geeky lights forums”.

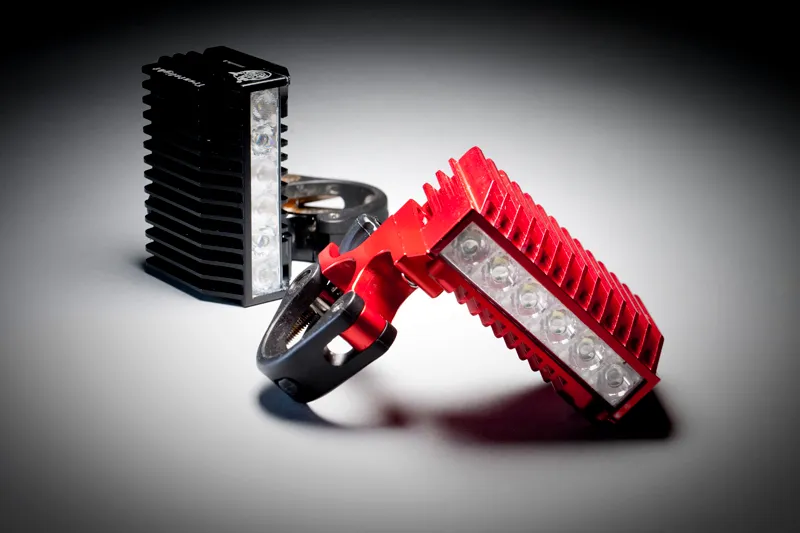

The LEDs he uses in his lights are some of the brightest available, Cree XPG R5s. Lupine have just started using the same LED in their top-of-the-range light, but Chris says: “I keep up to date with the LED progress and don’t buy thousands of them. I can swap to the best quality as soon as it becomes available, unlike the big players who have old stock to use up before they can release a new model.”

Experimentation

The design of the light cases came about through trial and error. “I played around with the LEDs and optics without putting them in a case," says Chris. "The light scattered everywhere, so I experimented with about 300 different designs. Eventually I got the light to shine out of the bottom and over the front wheel, just where you need it.”

The batteries and chargers are assembled and supplied by a friend and fellow “shed constructor” called Smudge. Also a passionate enthusiast, he furnished Chris with free batteries for his testing and prototypes. When Chris tested his final design he thought, “Wow this is good, but it’s taken 20 hours to make”.

"[I decided that] if I was going to build more of them, it wouldn’t be worth it if I had to hack all the material out myself. And I’d be bored silly," he says. So he approached a local engineering company to make the cases. They weren’t interested but referred him on to someone else who might be. After explaining his project, “this guy thought I was absolutely mad”.

Reproduction

The machinist asked Chris whether he had any drawings to work from: “I said no. I put a lump of metal in the milling machine and the design comes out of my head. This is probably why there have been a few failed attempts.” Chris handed him one he’d made and said, “I’d like 50 of these cases please".

"After the guy had stopped laughing, it just sort of happened,” he says.

It hasn't all been a breeze though. While the Troutelights were still in production, a super-bright bike light from China was released for £50. Chris realised he couldn’t compete with this product and was on the verge of quitting the whole business. But Smudge stepped in with help and moral support; he convinced Chris that the quality of his product would shine through in the end.

Marketing

Lots of people in the cycling community were already familiar with Chris and what he was doing because in the past “I’d make a light, use it myself and then flog it in the classifieds”. So, last autumn, he put a posting on a cycling forum titled: “Troutie’s new light. What d’you think?” This immediately generated 60 orders for the new Lumen Liberator.

"But I didn’t even have one!" he says. "The orders were rolling in and people were paying deposits yet there was no product. It was a bit scary.”

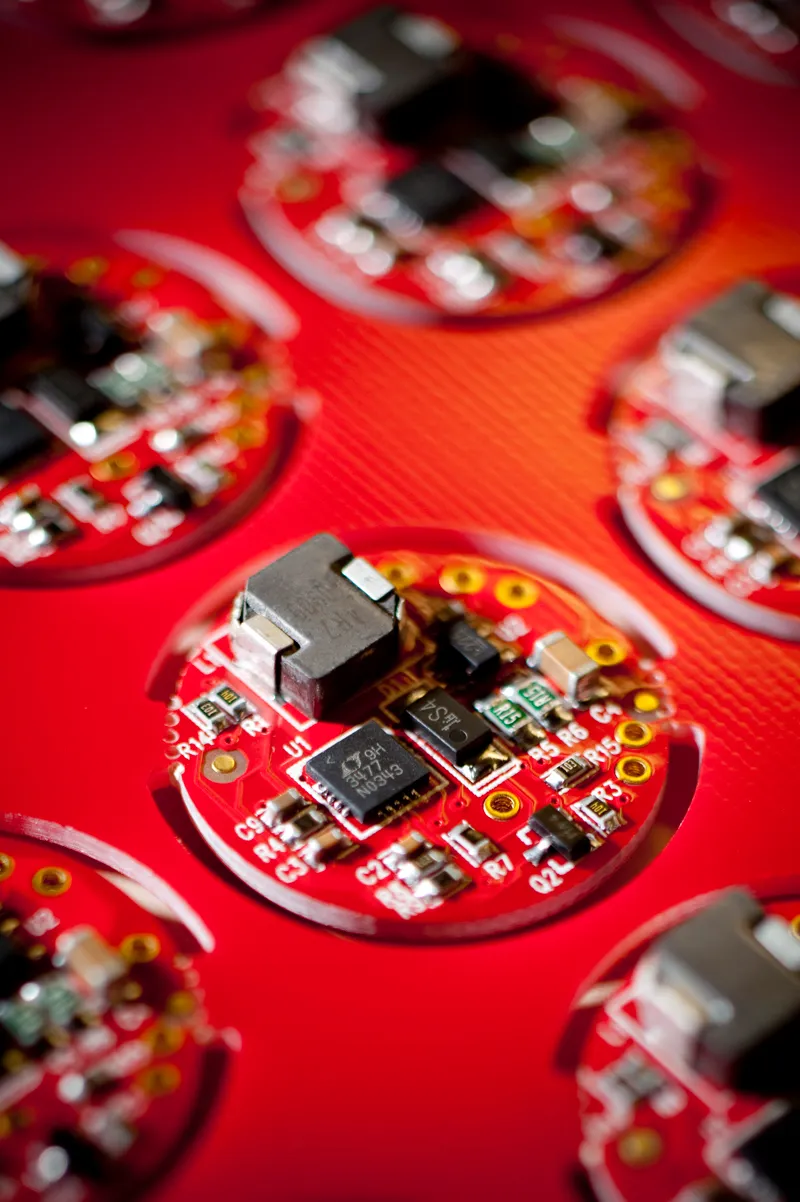

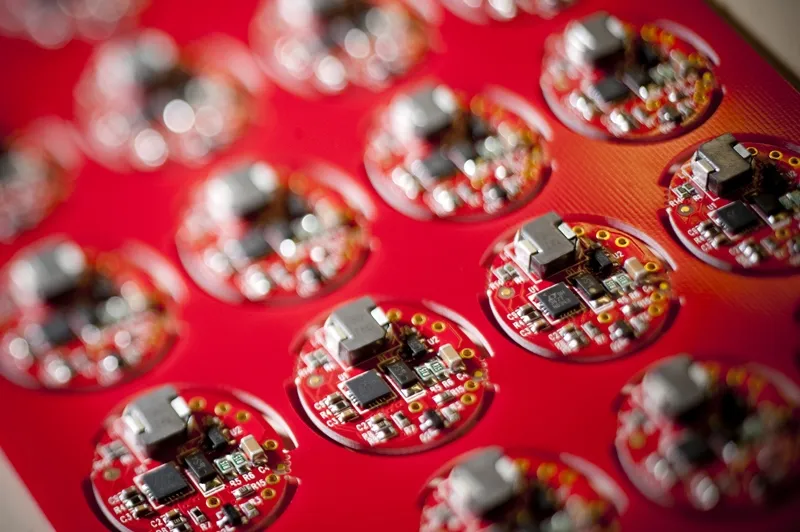

The number of postings on Chris’s thread went up to 1,200; something of a record for this forum. Even when the cases were made, Chris was still waiting for the electronic boards to come from America and the LEDs to arrive from Australia. "Fortunately people just hung on and hung on," he says.

Then all of the components arrived in the same week. Chris had to assemble 60 lights and get them posted to everybody. This took three weeks of working “in the mornings and the evenings, out in the garage with three coats on” in addition to his full-time job as a floor-fitter. Chris has now sold 120 lightsets, without any advertising.

International sales

I was curious to know if Chris’s lights are selling right across the UK; but apparently they are being purchased “by people on most continents of the world”. There are quite a few buyers in Scandinavia and Australia, and there’s even a British guy living in Dubai who wanted one for night-riding because it’s too hot to ride during the daytime.

“I’ve had some strange requests," says Chris. "There’s a kite-surfer in Brazil who wants to go for the world record for how far you can travel in 24 hours. Another chap in Finland uses a light for dog-sled racing and a bloke in Sweden wants one for running in the forest.”

For Chris, this is the most appealing part of what he does: “I just love the fact that obscure sports are also interested in using my lights. Sending them round the world for bespoke use is more of a buzz than selling them in large quantities.”

The future

Business is tailing off now because the winter is drawing to a close, but I’m interested in where Chris sees his project going. “I don’t want to send them out to China to be made, because then I become just a reseller of a product," he says. "I don’t want to let go of hand-building them. It must sound like I’ve got some strange Yorkshire ideals, but that way it’s still my project.”

Chris says that if he was to increase production and churn out 10 to 15 lights per day “it would get dull and having this sort of turnover would take the passion out of it”. So, he is more interested in developing new projects and continuing to build bespoke lights. He gets “lots of requests for one-offs – mostly from bikers – but this keeps it interesting". "[This season has] not made me rich, but it helps," he says. "The last model paid for a new milling machine.”

Why Troutelight?

“It’s my old nickname from school that stuck,” Chris says. Even his wife calls him Troutie.

For more information and Chris’s contact details, visit www.troutie.com. You can find Smudge's battery website at www.mtbbatteries.co.uk.