Building upon the success of their pre-built wheels, CrankBrothers are introducing a range of Cobalt cross-country and Iodine all-mountain components, including handlebars, stems and seatposts.

The move into cockpit component design is a natural progression for the US company. With wheels, pedals and adjustable seatposts already available, design minded riders can now tie a whole bike together with the Laguna Beach brand’s unique style.

“There are no longer just utilitarian products,” said Christina Orlandella, CrankBrothers' marketing director, describing how people crave affordable design. “There’s always an emotional connection to what people buy and our vision is that CrankBrothers are going to be the design company for the mountain bike.

"We do this by designing aesthetically disruptive, high-performance products – not just one or the other, but both. High performance is a given; it should be. The aesthetic disruption is something that changes the look of the bicycle and is unmistakably CrankBrothers.”

Three stems, five handlebars, three seatposts and two types of grip will be available this summer. Further components are expected to be added in time for the autumn trade shows, while the launch of Sage (freeride) and Opium (downhill) equivalents will likely be saved for 2011.

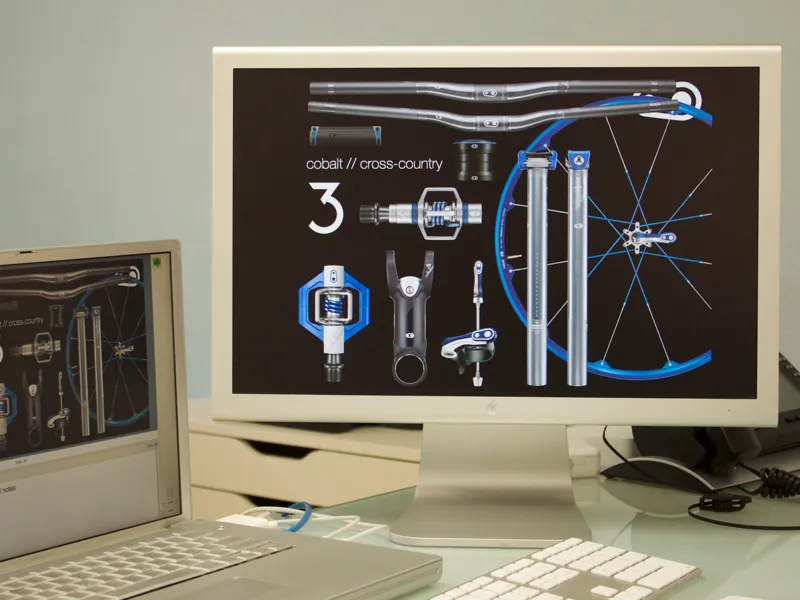

As with CrankBrothers' pedals – and there are new developments in this area too – the new components will have numbers rather than names. “These go to 11,” said Orlandella. Level 1 products are entry-level, level 2 are aimed at bikes costing US$800-2,000 and level 3 is the workhorse performance line for bikes in the $2,000-4,000 range. The '11' tag is set aside for ‘dream bikes’ – those that push past the $4,000 mark.

So, this summer we'll see a Cobalt 3 stem, Cobalt 2, 3 and 11 bars, and Cobalt 2, 3 and 11 seatposts for cross-country riders. On the all-mountain side there'll be Iodine 2 and 3 stems, Iodine 2, 3 and 11 bars, plus the existing Joplin 4 adjustable seatposts. Additionally, CrankBrothers offer both Cobalt and Iodine clamp-on grips.

Cobalt

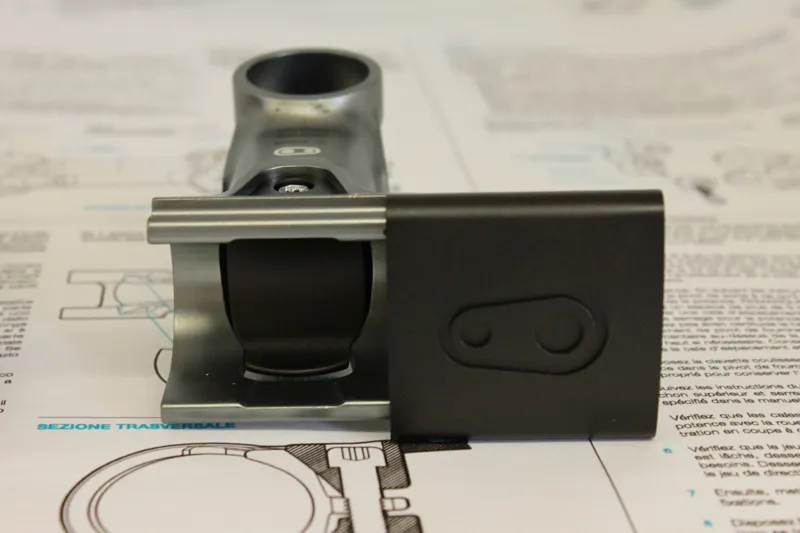

CrankBrothers have designed their Cobalt stem with just two Torx bolts. Two wedge-and-plunger systems are used to clamp the bar and steerer tube. There is no faceplate; instead, the handlebar slides through machined loops that are part of the stem’s body. The wedge-and-plunger system uses the large, smooth plunger to focus clamping force on the bar and steerer. This eliminates the crimping associated with wedge-only systems.

Even though the bar has to be woven through the front clamp, the stem can accommodate models with a 50mm rise. Only the Cobalt 3 stem will initially be available, but the design begs speculation as to the material of the 11 model. Our guess is that the Cobalt’s wedge-and-plunger system is an ideal clamping system for carbon. The way the stem body is designed, and the fact that it doesn’t require fasteners to thread into the body, reinforces this opinion.

Cobalt 3 stem and bar

The Cobalt 3 stem will be available in four colours. It’s forged from 7075 alloy and available in five lengths (8cm-12cm, 1cm increments) with a ± 6-degree rise. A 100mm stem has a claimed weight of 127g and a retail price of £89.99 (US$130). As part of CrankBrothers' new testing protocol, all of their stems meet CEN standards.

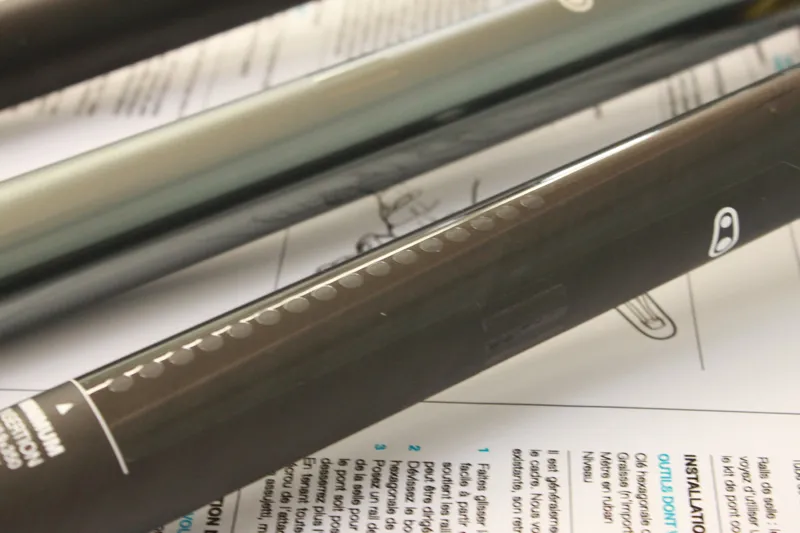

Three handlebars and three seatposts are also available in the Cobalt line. The primary difference between them is the material they’re fashioned from. The seatposts are available in four sizes (27.2, 30.9, 31.6 and 34.9mm), two lengths (350 and 400mm) and with a zero or 20mm offset. The 3 and 11 posts feature a unique recessed ruler, so riders can mark their preferred height(s), while the 2 has a laser etched ruler.

The Cobalt 11 post's height ruler. You're meant to fill in the dot at your preferred height

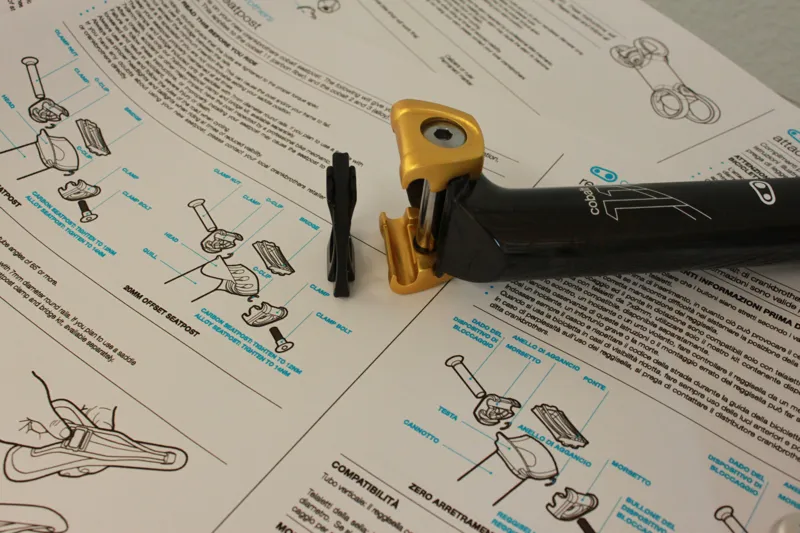

They all share the same one-bolt quick clamp, which uses a separate reinforcing support that fits between the saddle's rails before it's fitted to the post. Additionally, CrankBrothers offer a kit to fit sister company Fizik’s braided carbon railed saddles.

The Cobalt 2 bar is a basic alloy handlebar available in a 680mm width and either flat or with a 15mm rise (255g and 308g, respectively). Both models are fashioned from 6061 alloy. All of CrankBrothers’ new handlebars feature a six-degree back sweep. The mid-range bar costs just £41.99 ($50). The Cobalt 2 seatpost is forged from 7050 alloy, laser etched and costs £57.99 ($90).

The one-bolt seatpost clamp uses a separate stiffener to support the saddle rails

The Cobalt 3 handlebar is also alloy, but the 7075 variety. It features a complicated graphics treatment whereby it’s masked, sandblasted, anodised, polished and finally laser etched. It’s available in 680mm width in a flat version or with a 15mm rise. Claimed weights are 195g and 230g, respectively, and both cost £64.99 ($80). The Cobalt 3 post is fashioned from 7050 alloy, but features more machining and finish work that the 2 model, and costs £79.99 ($120).

The dream bar, Cobalt 11, is made of high modulus unidirectional carbon fibre. It’s available in a 600mm flat option that weighs just 132g or with a 15mm rise that’s 680mm wide and weighs 160g. Both cost £99.99 ($120). The Cobalt 11 seatpost is moulded from the same carbon fibre and at 172g (31.6, 400mm) is one of the lightest on the market. It passes a 350lb slip test and a 100,000-cycle dynamic load fatigue test, so it should be up to the task of taking some mountain bike abuse. It costs £174.99 ($220).

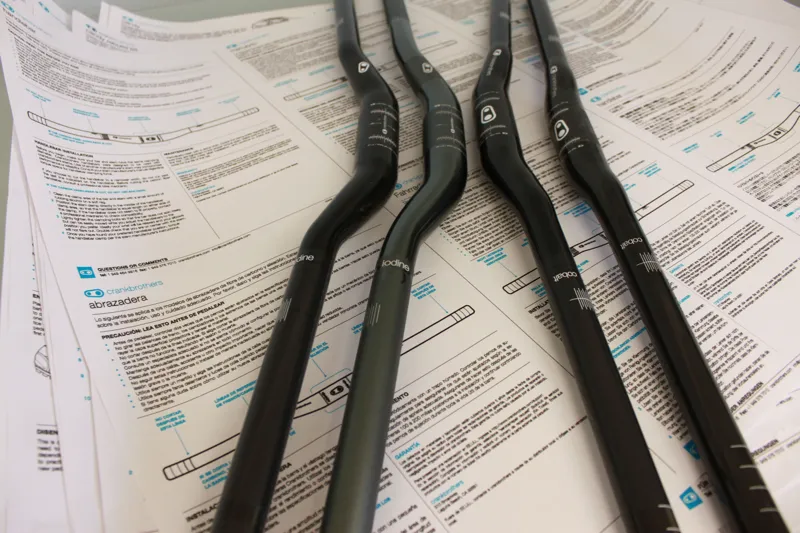

Handlebars: Cobalt 11 (foreground) and Iodine 3 and 11 (back)

Iodine

On the all-mountain side, the Iodine 2 stem uses a conventional faceplate that’s fixed with four T25 Torx bolts and a wedge-and-plunger steerer clamp. The stem is forged from 7075 alloy and available in six lengths from 70mm to 120mm with a ± 6-degree rise. It’s available in two colours, has a claimed weight of 175g (100mm) and costs £59.99 ($90). The Iodine 2 handlebar is fashioned from 6061 alloy and costs £41.99 ($50). All of the Iodine bars feature a 30mm rise, the option of 680mm or 700mm widths and a six-degree back sweep.

The Iodine 3 stem gets fancy with the use of a sliding, removable faceplate and dual wedge-and-plunger clamping system. It’s forged from 7075 alloy and available in six lengths. It’s claimed to weigh 169g (100mm) and costs £89.99 ($130). The Iodine 3 bar costs £64.99 ($80). It’s made from 7075 alloy finished with the same processes as the Cobalt 3 bar. Claimed weight for the 680mm bar is 238g.

Iodine 3'stem's sliding faceplate

Only one option is available for the high modulus uni-directional carbon fibre Iodine 11 handlebar: a 30mm rise and 680mm width. It weighs just 178g and costs £99.99 ($120).

Matching grips are also available. The Cobalt version is made of foam and weighs 96g. Available in blue or gold, it costs £19.99 ($25). The Iodine grip is made of Kraton rubber and weighs 136g. Available in black, blue and orange, price is the same again, £19.99 ($25).

The Cobalt grip family

Design focused, quality assured

When they showed us their new products, CrankBrothers were keen to stress that, although they are a design-led company, the quality and performance of their kit is up there with the best. They test all products to Cannondale’s standards, which are some of the most stringent in the bicycle industry, they only use what they call ‘A-list’ overseas suppliers – those who employ the highest internal testing standards – and have just formed a partnership with leading third-party testers SGS testing labs in Taiwan. They've even set up their own office in Taichung to oversee production, with a senior engineer, Matias Lauryssens, permanently deployed there.

Looking to the future, the company will continue to only produce mountain bike components. “CrankBrothers won’t be making anything for the road market,” said Orlandella. “We’ve got a following in mountain bike, so why try to be all things to all people?” This is hardly surprising when you look at the staff, who can be best described as a bunch of mountain bikers. Just about everyone from Maxine Irving, the ex-professional downhiller who runs CrankBrothers’ reception and front office, to engineers and customer service rides, and their first choice of location is always the same – off-road.