Modern bicycle disc brakes are marvels of engineering, with hundreds of parts working in harmony to slow your bike down in a controlled way.

They’re so good that it’s rare to have leaks, breakages or failures that aren't the result of a crash or some kind of damage.

They’re cost-effective, too, with the cheapest Shimano systems starting at around £35 for the MT200. Prices climb all the way to the fantastic Trickstuff Direttissimas at around £1,300.

When you do have to work on hydraulic disc brakes, though, not all systems are created equal. Whether it’s bleeding brakes or adjusting calipers, I have numerous frustrations about working with hydraulic disc brake systems.

As a professional mechanic, here are some of the things about disc brakes that irk me most – and you should try to avoid.

Absent bleed ports

Hope brakes are fantastic. They’re gorgeous-looking, designed cleverly, have heaps of power and modulation, a plethora of spare parts are available, and they’re made from high-quality materials. But I don’t like bleeding them, for one simple reason – they don’t have a bleed port on the lever.

Cars tend to stay the right way up (hopefully) and therefore a little air on top of the brake fluid reservoir is OK, because it's very unlikely for it to enter the braking system.

However, bicycles are frequently laid on their side, hung up and even turned upside-down. This means any air in the reservoir can make its way into the system. This is why bleeding a brake thoroughly to rid it of all air, not only in the brake system, but also in the reservoir, is so important on hydraulic disc brakes.

Hope brakes have a bleed port (although not a threaded one as with SRAM and Formula brakes) on the caliper, but there is no bleed port on the lever. Hope is one of the last mountain bike brake manufacturers not to have integrated a bleed port into the brake-lever reservoir, and it makes bleeding Hope brakes challenging.

There is an art to fitting the rubber diaphragm onto the top of the Hope lever reservoir after a bleed, but it usually results in some mess, because paint-corroding DOT (Department of Transportation) fluid is squeezed out.

This is tricky and it’s very challenging to rid the reservoir of all air before tightening the cap. This means even the best bleed of the brake system could be undone by putting the bike on its side and squeezing the lever, which can be frustrating.

Press-fit bleed nipples

I love Shimano brakes – the lever feel, the non-hygroscopic mineral-oil based fluid, the power and the modular nature of the system.

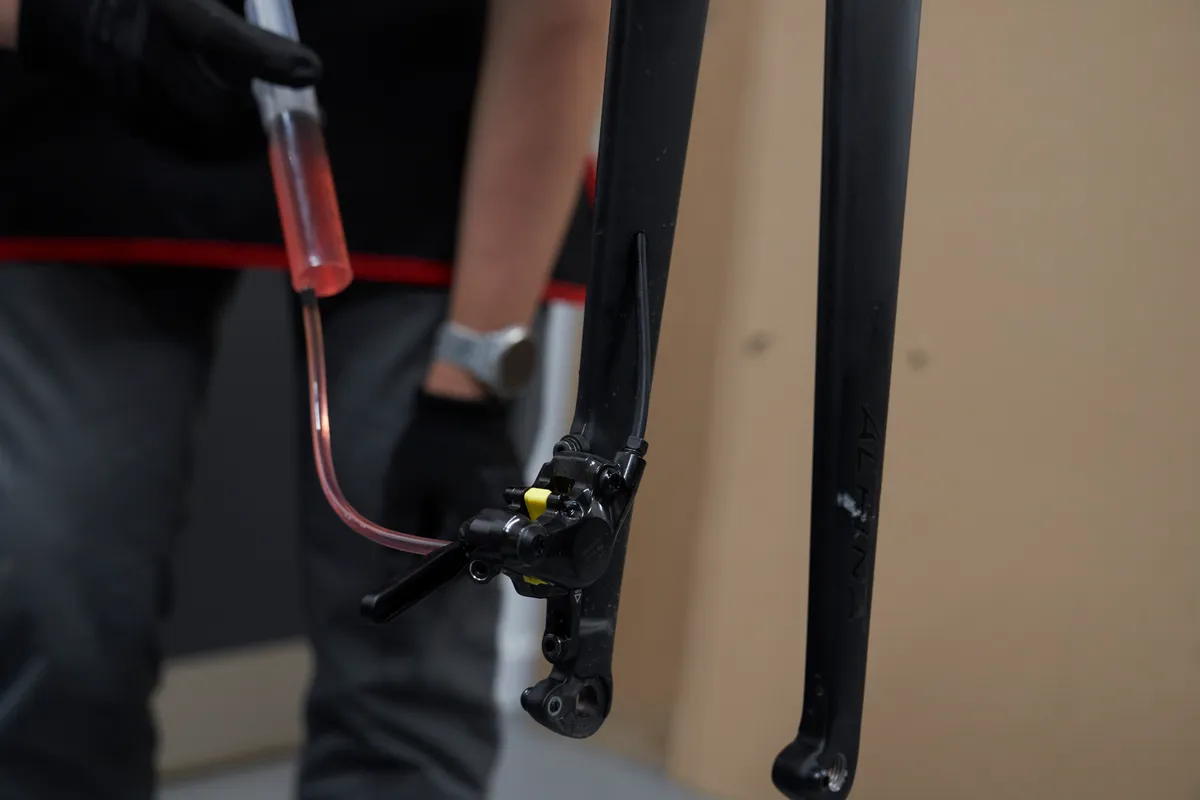

However, as a mechanic, I have a gripe when working on Shimano brakes. The bleed nipple on the caliper requires a tube to be press-fit and not threaded on.

Avid, Magura and Formula, along with many other brake brands, have threaded fittings for a bleed syringe to be screwed onto the brake calipers. This means you can create a positive, locked connection once the bleed syringe is threaded in.

With Shimano (and Hope), you’re relying on the fit between the hose and the bleed nipple. Shimano tries to optimise the situation by implementing a black plastic rectangle with a hole in, which ‘locks’ the hose over the nipple.

Yet there is an advantage to Shimano and Hope’s systems, which is that once the bleed is finished, you can simply lock off the bleed nipple with a spanner and there is (theoretically) zero chance of any air entering the system.

However, with the threaded fitting, it’s necessary to unthread the syringe, leaving the brake system open to the elements, before refitting a bleed-port bung. The chance of any air entering this way is lower than when fitting a brake-reservoir diaphragm followed by the cap – but it's not zero.

Flat-mount calipers

Mountain bike calipers use a standard called post-mount, replacing the defunct International Standard, where calipers mounted through bolts on the sides.

Each caliper was specific to a different rotor size, and there was no side-to-side adjustment to take into account hub spacing and frame tolerances. Because of this, some had to be shimmed with washers to keep them central, which was a fiddly and time-consuming process.

Post-mount is a versatile standard, enabling sliding side-to-side movement to adjust the caliper in the frame for different wheels or poor tolerances on the mount. The caliper design enables adaptors to be added underneath them and the same calipers to be used on different-sized disc brake rotors.

Road and gravel bikes use a similar but subtly different standard, called flat-mount. They work in a similar modular fashion to post-mount MTB calipers, but the calipers themselves are threaded and they mount on a slightly different axis. This is why I don’t like adjusting the position of flat-mount calipers.

When aligning post-mount calipers, it’s possible to look from above and align the caliper with the rotor on the axis you’re looking at.

However, flat-mount calipers aren’t as easy to line up. The axis of the caliper adjustment isn’t aligned with the opening where the disc is visible above the brake pads. So, instead of being able to stare down at the caliper from above and adjust it from side-to-side on a plane, it's a case of trying to anticipate the way the caliper will cant over to either side as you adjust it.

I have no doubt pro road and gravel mechanics have this down to a fine art, but to me, it feels unnatural.

It's getting better…

Ultimately, brake tech is the best it has ever been, with useful standards and manufacturers broadly considering the needs of the home and workshop mechanic when designing their systems.

Hope created a new standard in 2017 for its HB.160 range of bikes, where the caliper was radially mounted in line with the axle, which was seriously clever.

But the standard was not widely adopted and Hope returned to post-mount rear calipers in its more recent range of HB.916 bikes.

Shimano has recently introduced low-viscosity brake fluid, which adds another variety of mineral-oil based brake fluid into the mix.

SRAM has also adopted mineral oil for some of its high-end brakes, where previously they all used DOT fluid. There are advantages and disadvantages of using each type of brake fluid.

Perhaps, following widespread adoption of electronic shifting, electronic brakes similar to those seen in this Shimano patent application will be the next big thing.