Shimano has patented a pedal with force sensors and accelerometers built into the spindle, indicating it may be developing power meter-equipped pedals.

Perhaps of most interest is that the diagrams used appear to confirm Shimano is developing this concept around its popular SPD-SL clipless road pedal platform.

Given the key parts appear to be based entirely around the spindle, it’s also possible Shimano could be developing an SPD mountain bike pedal version as well (although, if compatibility with Shimano’s off-road pedal standard is what you’ve been waiting for SRM actually already has you covered).

The patent we have examined most closely was first filed in 2014 and granted in 2018.

A 'division' of a second patent that focuses specifically on how a piezoelectric sensor could be used within a pedal, as either a strain gauge or power source for a signal processor, was subsequently granted in November 2020.

While I've got doubts as to whether Shimano will bring the specific design described in these patents to market, it does raise the question as to if – and when – we might see an SPD-SL power pedal.

Given the popularity of Shimano's road pedals and the inherent benefits of pedal-based power meters, it's a product that's no doubt in high demand.

Thanks to Michael Taylor of intellectual property law firm Abel and Imray for his invaluable help with deciphering this patent.

Looking for a SPD-SL compatible power meter pedal? Read our full review of the Garmin Rally RS200 power meter pedals, the world's first power meter pedal with native SPD-SL compatibility.

What does the Shimano power meter pedal patent tell us?

Originally filed in August 2014 and granted in June 2018, the patent details both the arrangement of the sensors and how the data from those sensors is processed and transmitted to a cycle computer.

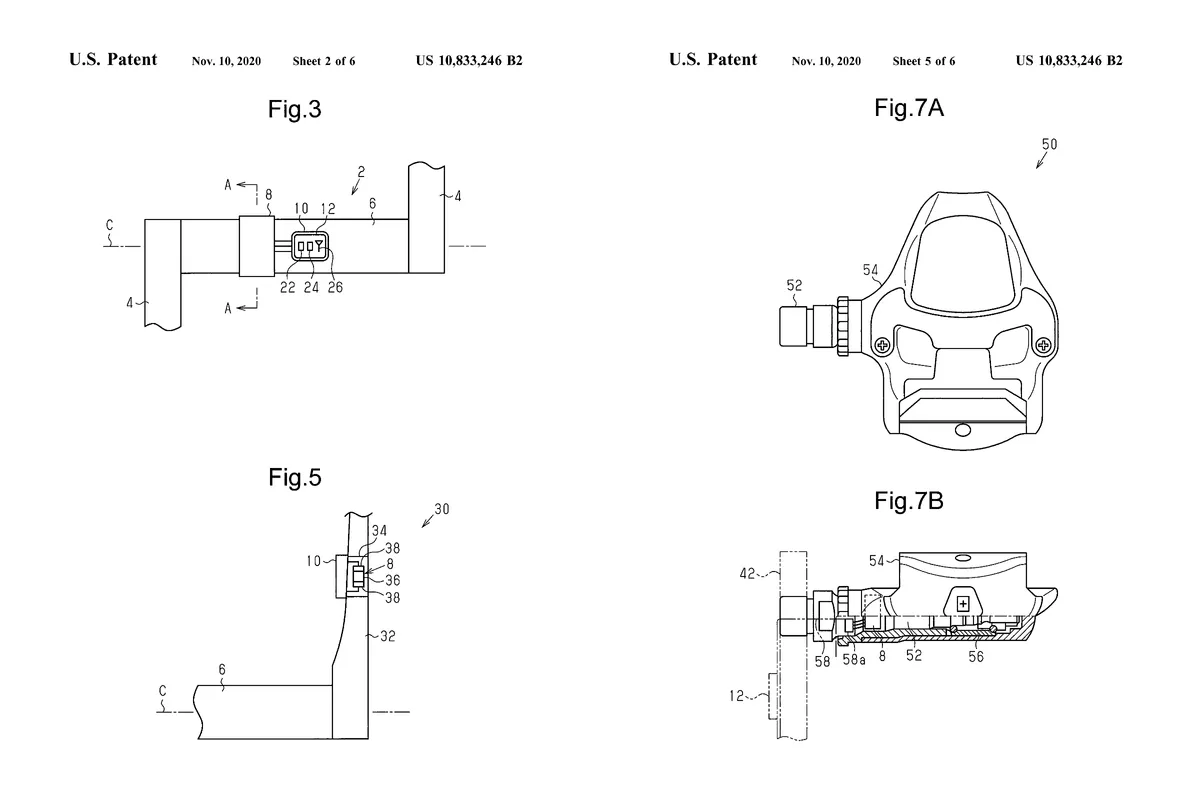

The patent shows an arrangement of strain gauges and inclination sensors on a standard Shimano pedal spindle. A cadence sensor is also located on the inside of the threaded portion of the spindle that attaches to the crank arm.

As with other power meters, the strain gauges are used to determine force (or torque) and the cadence sensor measures how fast the rider is pedalling (measured in revolutions per minute). Power is calculated by multiplying these two figures together.

The inclination sensors are biaxial accelerometers that are likely used to determine how fast each pedal is moving throughout the pedal stroke, providing further information on how the pedals are moving throughout their rotation.

This would presumably enable riders to access similar data as that gleaned from Garmin Cycling Dynamics, for example.

So far, so typical.

The patent was specifically granted for the way Shimano has added bore holes to the spindle, however.

The bore holes allow wiring to come out through a hole in the centre of the spindle, leading to a ‘controller’ arrangement that contains a processor, wireless transmitter and a battery on the crank arm.

The diagrams show the pedals as being removable from the crank arms, so the controller arrangement is possibly also intended to be removable (i.e. not permanently affixed to the crank arm).

The patent also says the wire emanating from the pedal will have a plug-in connector to the controller. The controller arrangement could be designed to be permanently affixed to the crank arm, and the pedals simply removable for charging purposes, for example.

However, given one of the key advantages of power meter pedals is the ease with which they can be moved between bikes, a permanent fixture on the crank would seem counterintuitive.

On the subject of charging batteries, the text is coy on precisely how the pedals would be powered.

The diagrams show a dry cell or rechargeable dry cell battery integrated into the crank arm controller, but the detailed description also makes reference to the possibility of using solar cells or piezoelectric devices (where electric charge is generated as a result of the response to mechanical stress), either independently or as part of the pedal body itself.

The aforementioned patent granted in the US in November 2020 expands on the concept of the pedal being powered by a piezoelectric device.

It’s worth noting that this is not a new patent per se – it is a ‘division’ of a patent originally filed in July 2015 and published in March 2016. However, the fact this has been granted so recently could suggest that Shimano is still seriously exploring the concept.

At its broadest, the patent protects the idea of a bicycle component comprising a ferroelectric film with electrodes embedded, which can generate power. This could then be affixed to – among other things – the spindle of a pedal.

“The signal processor [the controller]” could then be “operated using electric power generated by the ferroelectric film," according to the patent.

Will Shimano bring this power meter pedal to market?

In this exact form, it seems unlikely.

The power meter market has developed rapidly in recent years and there are now many sleek, affordable and accurate options available.

The idea of having wires that come out of the rear of the pedal spindle to attach to a separate pod on the crank arms seems inelegant, especially compared to power meter pedals from competitors, such as Garmin's Vector 3 pedals and the Favero Assioma Duo power meter pedals.

Furthermore, if those pods have to be permanently attached to the crank arms that diminishes one of the key advantages of power meter pedals – the ability to quickly and easily swap the power meter between different bikes and cranks.

If Shimano were to produce a power meter pedal, I believe it’s more likely it would take the strain gauge and accelerometer arrangement found in this patent and apply it to its SPD-SL pedals in a manner more akin to that of the Vector 3.

The obvious issue there, though, is that Shimano would need to find a way to do this without infringing on any patents owned by other commercial entities such as Garmin and Favero, or come to some sort of agreement with them.

That said, Shimano is clearly seeking to protect this technology. The fact it has also filed a divisional patent application some years after it first filed the original application, suggests Shimano could still be working on this, or something related, after all.

What does Shimano say?

We contacted Shimano but it declined to comment on the patents.

Why might Shimano want to make power meter pedals?

As many of you will be aware, Shimano already makes a dual-sided, crank-based power meter, the FC-9100-P.

The brand was a late entrant to the power meter market, though, and as we found in our detailed FC-9100-P review, it also (initially, at least) suffered from issues surrounding left/right accuracy and temperature compensation.

There has been some speculation that any potential issue could possibly stem from the crank design. Specifically, that the driveside crank has an asymmetric design intended to improve power transfer.

It’s noteworthy that the Shimano power meter appears to be a retrofit to the existing Shimano Hollowtech II crank design, rather than a crank designed specifically to be a power meter from the ground up.

Moving to a pedal-based power meter offering could allow Shimano to continue with its asymmetric crank arm design and skirt any potential issues.

Power meter pedals, like the Garmin Vector, PowerTap P series and Favero Assioma Duo pedals, have also increased in popularity in recent years as they offer a number of distinct advantages over crank-based options.

Firstly, power meter pedals offer the potential for very quick and easy swapping between bikes, with most being as easy to install or remove as any standard road pedal.

Power meter pedals also don’t tie you to a set crank length, or crank and bottom bracket system, like crank arm or crank spider options do, which can be an issue for some cyclists with more than one bike.

There’s also an argument that, because they’re measuring power as close to the source as possible, they also have a theoretical accuracy advantage because they don’t need to account for as many losses in the system.

Given these advantages and benefits to the end user, why didn’t Shimano (and everyone else) just make power meter pedals to begin with?

Most likely because it was previously too difficult and/or expensive to shrink everything to the degree required to fit within a lightweight road pedal – there’s a lot more room to fit strain gauges, accelerometers, processors, transmitters and batteries on, in or around cranks, for example.

Even now, as of November 2020, only Garmin has managed to bring a power meter pedal to market which has everything housed completely within the pedal body and spindle.

This isn’t necessarily important for functionality – Favero’s Assioma Duo pedals work perfectly well with the somewhat bulbous pods on the spindles, after all – but Shimano may not have been as willing to compromise on the aesthetics of its much-loved pedals.

From a functionality point of view, there’s room for a much larger battery in and around cranks, too. Shimano’s FC-R9100-P power meter offers 300 hours of rechargeable battery life, compared to the 50 hours the Favero Assioma Duo offers, for example.

Cranks are also more protected from crash damage than pedals, meaning they offer a potential durability advantage, especially for racers.

Like most products then, there are advantages and disadvantages to both types of design.

What’s next?

We’re still expecting to see Shimano’s flagship Dura-Ace road groupset get a complete refresh in the near future. (Update 31/08/21: The new Shimano Dura-Ace R9200 groupset has now been launched).

Given the direction of the market – training with power is more accessible than ever and an increasing number of high-end bikes are being specced with power meters as standard – it seems fairly likely that Shimano will refresh its Dura-Ace power meter offering at the same time.

Could we even see a Shimano power meter option at the second-tier Ultegra level?

As of yet, we’ve not seen hide nor hair of the new groupset components. We do have a few predictions for what we might get from the new Dura-Ace, but until we see the cranks or pedals either in person or in photographs, we likely won’t be able to determine exactly what Shimano is or isn’t planning.

One recent (and significant) development in this sphere was Shimano’s acquisition of Pioneer’s Cycle Sports assets and IP, in February of this year.

As we commented at the time, Pioneer generally held a strong reputation for its power meters, which had been built around Shimano cranksets.

Although it’s only been a short time since that acquisition, it’s possible Pioneer may have had new products at advanced stages of development that Shimano could repurpose.

Despite the patents uncovered, if I were a betting man, I’d wager we’ll see Shimano continue with a crank-based power meter design, still based around its existing Hollowtech II technology, rather than an SPD-SL power pedal.

Given patents can typically only last up to 20 years from their filing date, could it actually be more likely that we’ll sooner see SPD-SL compatible power meter pedals from a third-party manufacturer instead?

With the SPD-SL design originally launched in 2003, any patents Shimano has for the platform could expire in the next few years, potentially opening the door for power meter companies to build their products around it.

Either way, it looks like the rapidly expanding power meter market won’t be slowing down anytime soon, which is great news for riders.

Whether from Shimano or a third-party, we at BikeRadar would very much like to see SPD-SL compatible power meter pedals at some point.

Some (myself included) feel that Shimano SPD-SL is a slightly superior cleat system to Look Keo-style systems. The SPD-SL pedalling platform is a little wider, for example, giving a larger, more stable contact area between the cleat and the pedal body.

SPD-SL cleats also have a marginally larger fit adjustment range than Look Keo-style cleats, and Shimano SPD-SL pedals are legendary for their reliability.

For those riders already using Shimano SPD-SL cleats (and that's a large number of road cyclists), an SPD-SL power meter pedal system would represent an extremely easy and enticing option for training and racing with power.