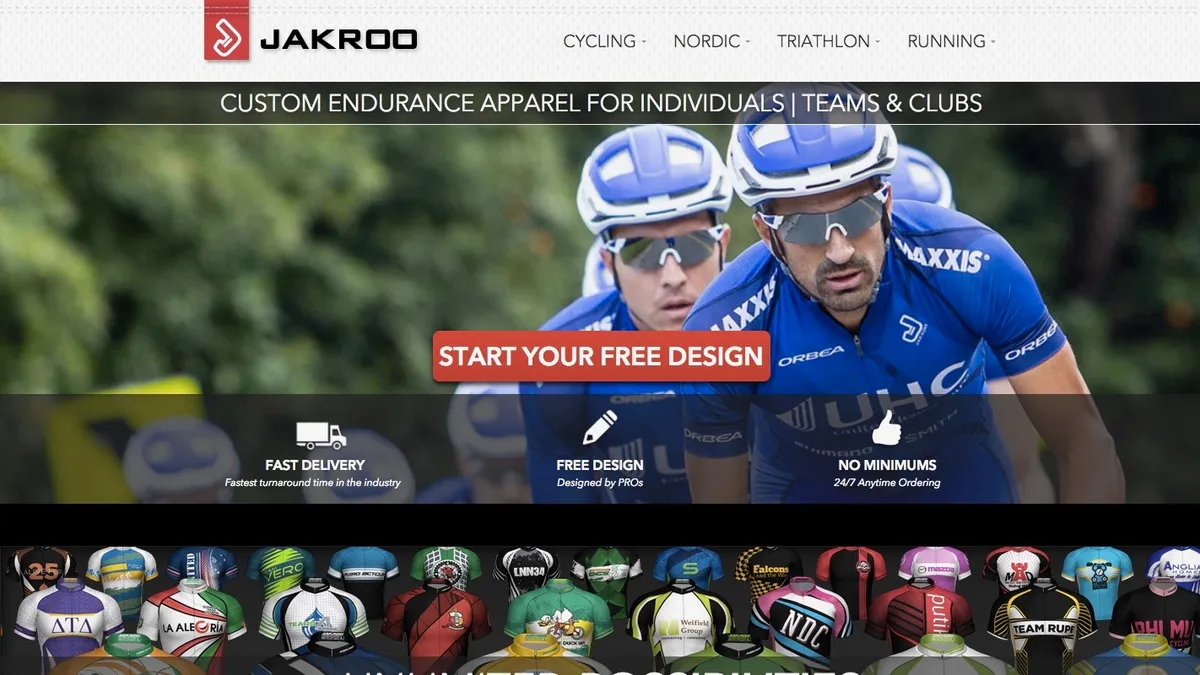

Cyclists have more options than ever for buying custom-printed cycling kits. Whether shopping for head-to-toe clothing for a huge club or just a single jersey, you can find a company that will design, produce and ship to your home.

- Rapha launches custom clothing tool for quick and easy online kit customisation

- Endura launches new custom kit option

- Custom MTB jerseys from Sombrio now available

Type of clothing, turnaround times, pricing and minimum-order requirements vary considerably, and this guide will help you determine the best fit, based on your priorities.“It is important to figure out what your needs are,” says Doug Williams of Curve. “Do you just want custom graphics on whatever piece made wherever? Do you want a really custom approach with options for your needs in climate, fit, amount and type of use, price and turnaround time? A free event jersey for 500 people does not need to be the same level as that which a team member will train and race in all season — or more. Don't be afraid to ask specific questions.”

Pactimo co-founder Karl Heidgen echoes this philosophy of choosing a custom company based on your team's priorities. "There are many viable options when it comes to clothing suppliers," Heidgen says. "Make a list of the three most important things to your team — delivery time, reliability, customer service, quality of clothing, print quality, price, selection — and then stick to finding the best solution based on those needs."Once you have settled on a supplier, make sure every last detail is spelled out in an email or in a contract. "Get it in writing!" Heidgen says. "Pricing, delivery date, everything that has variable expectations. Leave nothing to be interpreted. Finally, get your team organized. Your order is only as fast as the least organized member of your team."Delivery typically takes between two and eight weeks from the time the order is approved, so get started now by reading the tips below.

Size of order

As the chart below illustrates, companies vary in how many pieces you must order to get a custom kit going. The more you buy, the cheaper each piece is. Typically, once you have placed the first order, reorders require much smaller minimums (even a single piece), since the artwork is already produced.

A high-mileage masters racing team has different demands than a club looking to make custom jerseys for a one-time charity ride. Some companies, like Capo, specialize in quality garments but require a 35-piece order. Other companies, such as Pactimo and Mt Borah, can get you going for an order of only five or six pieces at a reasonable cost. And a few companies like Jakroo and Louis Garneau will design and sell you a single piece, but you will pay a premium for this.

“If you come to us looking for a two-week turnaround, with your names on the jerseys, for a club of five people, that’s not in our wheelhouse,” says Capo co-founder Gary Vasconi. “But if you’re a bigger team with higher-quality needs looking for a complete clothing solution, that is absolutely our specialty. I’m never badmouthing any of our competition; we all have a place in the market. It really depends on the needs of the customer.”Some companies do minimums by a type of item, such as a bib short. Others, like Champion System, do it based on total number of pieces. “Our CS-10 program has a minimum of only 10 total main pieces,” says Champion System’s Kelly Reed. “There is no per-item minimum; this means any combination of 10 total main items, for example three jerseys, two cycling shorts, two bib shorts, a trail jersey and two jackets.”

Pricing based on minimum order / 10-piece order

Array

Note: All these companies offer multiple levels of clothing; prices listed are for their most inexpensive offerings.

Quality of the fabrics and construction

All companies will tell you that they use high-quality materials and construction techniques. But how can you know what’s great and what’s not?

“The difference between average kit and great kit is fabric and chamois pad,” says Panache founder Don Powell. “Great fabric means great color, compression that will last multiple years, and technology in the process that does not blur. Great chamois pad means comfort, pliability and breathability.”

We would also add that a great chamois pad means proper placement, too. Also be sure to check the feel of the seams; are they stiff or pliable?

Asking around for recommendations is always a good practice. Ask people on group rides for their thoughts on last year’s team gear, and their experience with custom companies.

At BikeRadar (both for BR gear and for other teams’ wear), we have appreciated custom clothing from Alé, Castelli, Capo, Giordana, and Panache.

Try on the clothing if you can. Many companies will ship you a fit kit once you've decided to do business with them. This is a good way to get a feel for the product — but getting your hands on a sample beforehand is even better. Just make sure that what you check out is what you buy, as many companies have different levels of product. “Look closely at the chamois offer,” says Louis Garneau's Heidi Myers. “Think about how much time you will spend on the saddle.”Most custom clothing is manufactured in China, Eastern Europe or Western Europe, but a few custom operations do exist in other regions such as North and South America.

Companies like Alé and Giordana will tell you Italian production is the best way to go, while companies like Jakroo or Pactimo that build in China defend the quality of their product, as they own their own factories there.Bottom line: Do whatever you can to get a good feel for the product before you buy.

Artwork design

"Art is the most time-consuming part of a custom project,” says Patrick Tess, Castelli’s custom team sales manager. “Make sure you have high-resolution art files to submit the company you choose to work with so you can get through their art process efficiently."

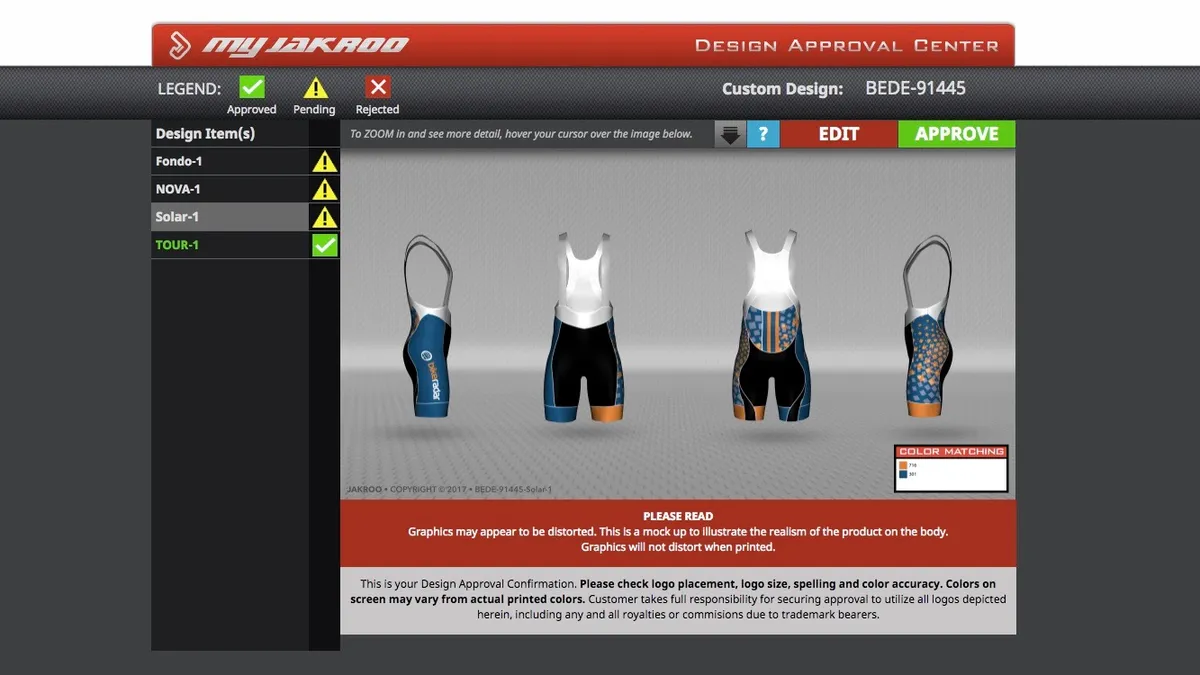

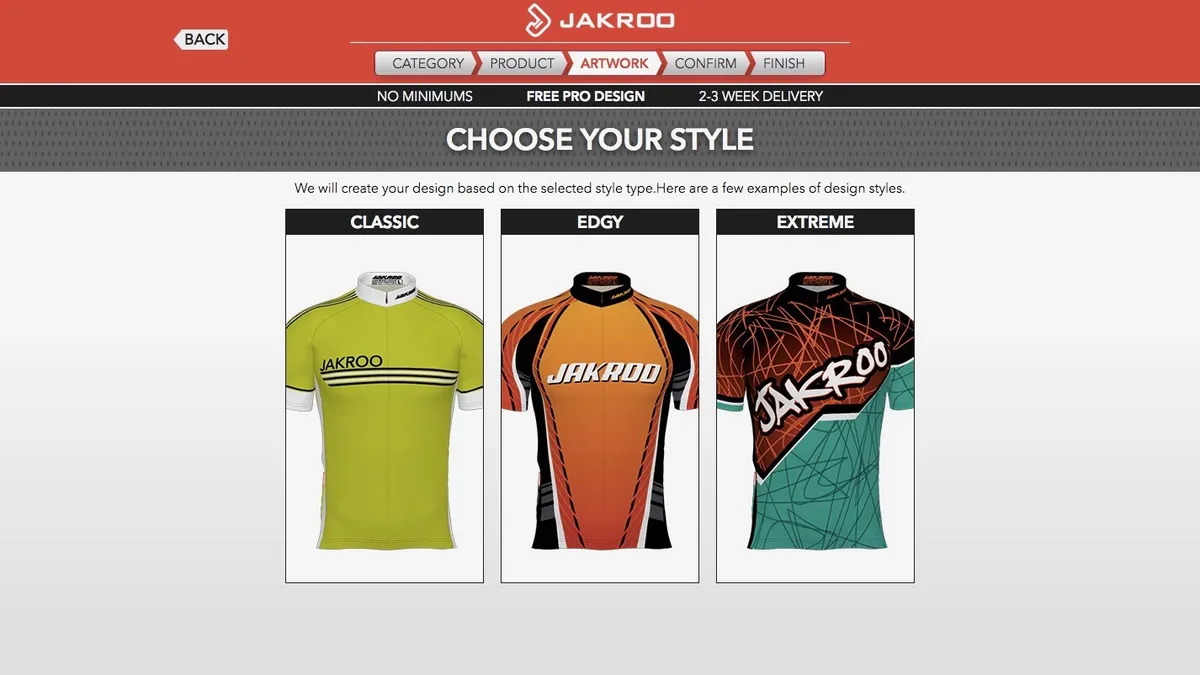

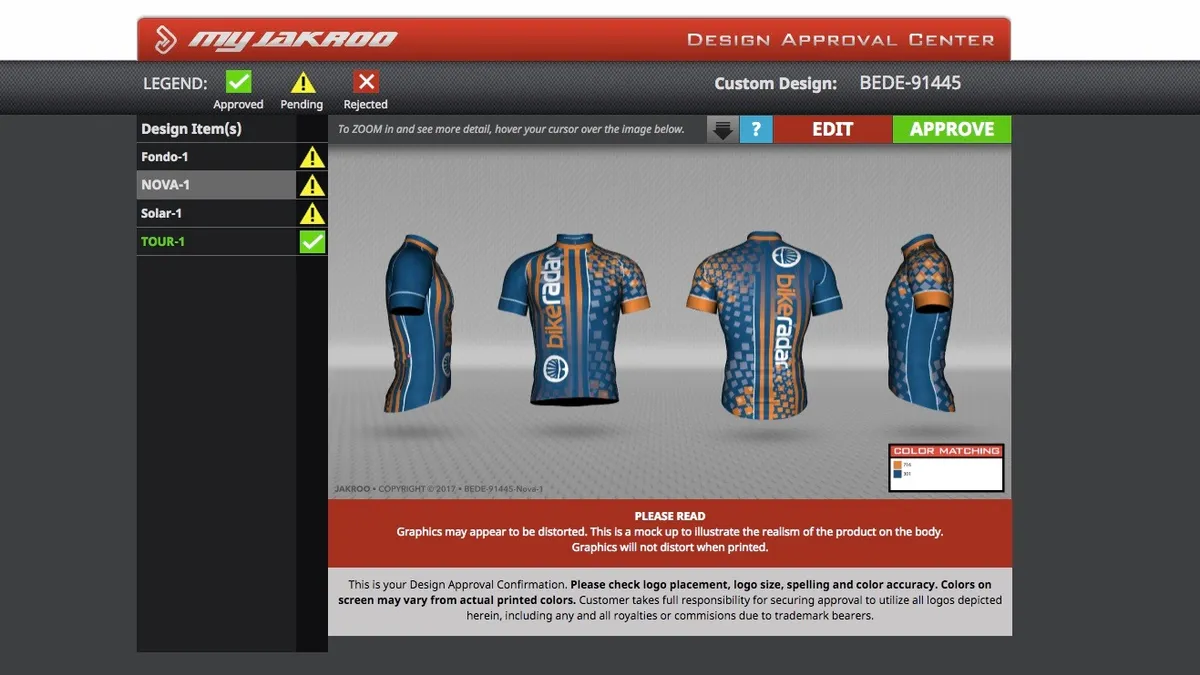

All companies will help you design your kit, but policies vary on cost. Some companies include it, others charge hourly. Make sure to ask for the specifics of how the process will work, says Verge vice president Kurt Sheerer. “Once you pick a US-based vendor, are you surprised when you have to work with an artist in a 17-hour-different time zone? At Verge we have an in-house art team that is always ready to work with customers during normal US business hours.”Some companies like Jakroo have integrated the design into their websites, so you can upload your logos, choose colors and select the general direction of the design. Then, there is some iteration back and forth until you are happy with how it looks.As with other steps in the process, ask plenty of questions about what to expect.

“Don't be afraid to ask questions and ask for help when needed," says Alchemist founder Jeff Wu. "The good companies in the business welcome your questions and input. You should not only get the product you want, but your experience along the way should be enjoyable. Designing a jersey or kit should be fun."

Ordering process

An increasing number of companies offer online ordering systems, which can simplify some steps of the ordering process, but can also disconnect you from the people involved. Ask how the company operates, and whether (and when) live customer service reps are available. “We set up an online store with your team's types of clothing and the team's unique design so team members know what they are ordering,” Powell said of the Panache process. “Called 'My Team Store,' this is the same platform as our own panachecyclewear.com store, including Quick Order shopping and a fast shopping cart. The My Team Store is private and only accessible to team members via a unique URL. Individual team members place and pay for their orders, thus no Excel spreadsheets, no tracking of orders and changes by the team manager. Once the My Team Store closes — at the discretion of the team manger — we go to production, and four to six weeks later we direct-ship the individual orders to each team member."

Jakroo and other companies offer a similar deal where each team member can get their own order at home.

Correct sizing for everyone on your team

With custom clothing, the company is only making what you order, so get the sizing right. There is no sending it back for another size later. “Always request a fit kit,” says Primal Wear’s Tim Baker. “A fit-kit party is a great teambuilding exercise that can be held at local bike shop or sponsor’s facility. Most companies will offer the kits by simply reserving a credit card. Primal provides fit kits for all of our cycling apparel offerings. We have different cuts, including Helix, Race Cut, Sport Cut and Loose Fit. It is important to know which style is appropriate for your team or club.”

Primal doesn’t charge to ship fit kits; some other companies do, so ask first, but certainly have everyone try on every type of clothing they intend to order. Sometimes jackets fit differently than jerseys, for example, so just because you're a medium in one thing doesn't mean you're a medium across the board.Ladies — make sure you are happy with the chamois options, as well as the jerseys and the short and/or bib shorts. Some companies have minimum-order requirements about including women's clothing as part of the order; others do not. As with everything else, investigate and get the agreement in writing.

Cost

Even within a given company, there are typically varying levels of quality and corresponding price. The chart above only lists prices for starting-level jersey and bib short prices for a few custom companies. Better stuff usually costs more. And buying more brings the individual price down.

Beyond that, be careful to ascertain what other costs there may be. Does the company charge to ship you a fit kit? Do they charge for artwork set-up? Are there price breaks built into the contract should they deliver late?

Turnaround time

“Make sure that if you are promised a deadline, it’s on the contract. We see too many stories of orders produced in longer time than advertised,” says Louis Garneau's Myers.

When companies quote their turnaround times, they are referring to the period between your final approval of the order and the delivery of the order. Setting up the design and getting all your teammates to decide on what they want is not figured into this.

With that in mind, the earlier you order, the sooner you’ll be riding in your new custom gear.