Tubeless tyre technology for bikes is exactly what you’d imagine from the name – it does away with inner tubes, working in much the same way as the tyre and rim of a modern car.

Tubeless is now the default option for mid-range to high-end mountain bikes and gravel bikes, and it’s becoming increasingly popular for road bikes too.

This guide covers the basic principles of tubeless, and we’ve got separate advice on tubeless setup for road bikes and tubeless setup for mountain bikes.

Don’t miss our guides to the best tubeless road tyres, the best mountain bike tyres and the best gravel tyres.

Also, if you want to optimise your tyre setup for speed, comfort, grip and puncture protection, we've got in-depth guides to road bike tyre pressure and mountain bike tyre pressure.

If there are any technical terms or jargon that aren’t familiar, scroll to the end of the article for a full glossary.

What is a tubeless tyre? How does a tubeless tyre work?

A tubeless tyre looks like a standard tube-type clincher tyre but requires no inner tube and, once ‘seated’ (seating is the process of snapping the beads into position), it forms an airtight seal with the rim.

A valve just like the one you’d find on an inner tube is fitted directly to the rim.

For the system to work, neither the rim nor tyre can leak air, so the tyre needs to fit tightly to the rim.

Sealant, poured into the tyre or injected through the valve, helps plug any tiny leaks. This sealant stays liquid inside the tyre and will heal small punctures suffered while riding.

Tubeless tyres are not to be confused with tubular tyres. Tubulars (also known as ‘tubs’ or ‘sew-ups’) are a traditional type of tyre that’s glued or taped to a tubular-specific rim. They are still widely used in road racing and cyclocross but have otherwise largely been replaced by high-performance clinchers.

What are the advantages of tubeless tyres?

The number one advantage of tubeless tyres compared to standard clinchers with inner tubes is they can be run at lower pressures without the risk of pinch flats.

A pinch flat occurs when your tyre hits an obstacle (such as a rock or the edge of a pothole) and deforms to such an extent that it squashes the inner tube against the rim. This leads to a characteristic ‘snake bite’-style double puncture.

With no inner tube to trap, and sealant in the tyre to heal small punctures, a tubeless setup is much less prone to flatting overall, and so enables you to reap the benefits of lower tyre pressures.

These include greater comfort, and potentially more grip and speed too, although the relationship between tyre pressure and performance is complex, so it’s hard to generalise.

Tubeless tyres may also have lower rolling resistance and therefore be faster than an equivalent tubed setup, but again it's hard to generalise because there are many variables. It depends exactly what you consider to be an apples-to-apples comparison.

There is a general consensus that tubeless tyres roll faster than tubulars, though, and this is driving a gradual adoption of tubeless by pro road racers.

The advantages of tubeless are pretty clear-cut for mountain bikes and gravel, but the picture is more nuanced for road use – many riders feel the added complexity is not worth the benefits.

What are the disadvantages of tubeless tyres?

Tubeless setup and maintenance is inherently more onerous than using inner tubes, tubeless tyres cost more than non-tubeless tyres, and you’ll need to keep buying sealant.

Some tubeless tyres mount easily and will seat on the rim using a normal pump. However, this often isn’t the case and some tyres are tricky to mount and/or need a dedicated tubeless inflator or air compressor to seat.

Sealant can be messy and needs to be renewed periodically – typically every few months – because it gradually dries out.

Tubeless tyres also need to be pumped up more frequently than tubed tyres – it’s advisable to check your pressures before every ride.

Do I need special tyres and rims to go tubeless?

For the best and safest results, tubeless requires both tyres and rims designed specifically for the job. Tubeless tyres have stretch-resistant beads to prevent blow-off under pressure and casings that are sealed to prevent air loss.

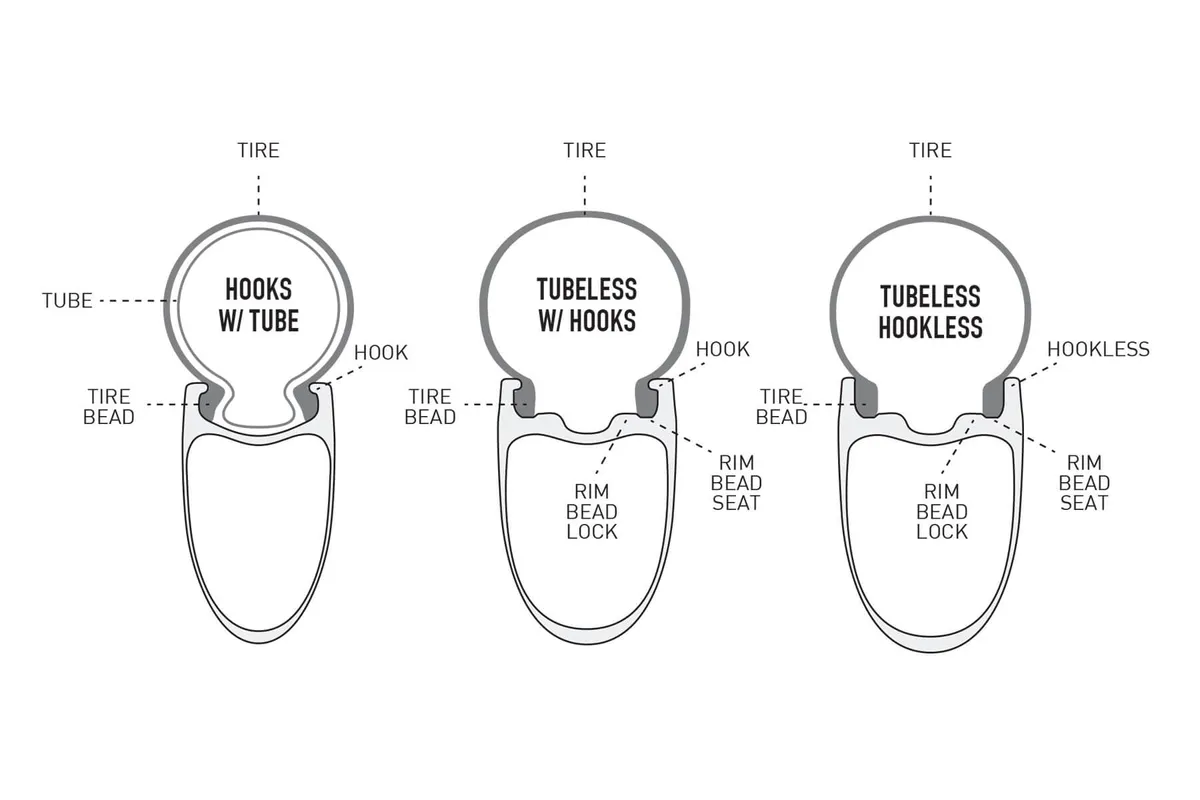

Rims vary in design but usually have a central channel to make tyre fitting easier, and humps that keep the tyre beads locked in position. The majority also have bead hooks to aid tyre retention, but hookless rim designs are also common and some brands claim these offer an advantage.

The benefits of hookless can be a stronger rim construction, a decrease in weight, increased aerodynamic performance and typically lower manufacturing costs. However, tyre choice is limited with hookless rims compared to more conventional rims with bead hooks.

Some brands take variations on hooked or hookless rims. Campagnolo, for example, uses a ‘Mini-Hook’ standard on its Levante gravel wheelset. This is claimed to combine the advantages of hookless and hooked rims while fully complying with ETRTO clincher and tubeless tyre safety standards.

It used to be common in the mountain bike world – and cyclocross/gravel to some extent too – to run standard tube-type clincher tyres and/or standard clincher rims tubeless.

However, with the choice of proper tubeless tyres and rims now on the market, there’s not much incentive to do this. Results with homebrew setups vary greatly, and it’s definitely not the easiest or safest option.

With a road bike, you should never run a non-tubeless tyre tubeless or attempt to convert a standard tube-type rim. The higher pressures used on the road make this dangerous and the consequences of failure can be serious.

Tubeless-ready vs. tubeless-compatible

These terms are sometimes used interchangeably and don’t have standardised definitions.

For some brands, a tubeless-ready rim is exactly that, and all you need to do is insert a valve (which may or may not be included with the wheels), fit an appropriate tyre and add sealant.

If a wheel is described as tubeless-compatible, it’s likely you’ll also need to fit tubeless tape to seal the rim.

In the road world, it’s not uncommon for bikes to ship with tubeless-compatible wheels, but non-tubeless tyres.

That means you’ll need to fork out for a set of new tyres in addition to the other bits if you want to ditch your inner tubes – a significant extra outlay.

Hookless rims are only suitable for tubeless-specific tyres. You can usually fit an inner tube if you need to (for example, as a get-you-home measure – you’ll need to remove the tubeless valve first, of course), but you can’t fit a standard tube-type tyre because there’s a risk it will blow off the rim.

Tubeless standards are a bit of a mess

For mountain bikes, tubeless compatibility is mostly straightforward but tyre designs vary and some will be more porous (and hence require more sealant to hold air) than others.

In the late nineties, Mavic created the UST standard (Universal System Tubeless), and this is only designed to work with UST-conforming tyres and rims.

These tyres are made to an exacting specification and are heavier and more airtight than many ‘tubeless-ready’ designated tyres.

Otherwise, you should expect any tubeless-ready mountain bike tyre to work with any tubeless-ready mountain bike rim, unless the respective manufacturer explicitly forbids it.

For road and gravel bikes, things are a bit messier. Shimano and Hutchinson introduced a road tubeless standard in 2006, but unlike the UST mountain bike standard it wasn’t widely adopted.

This led to a long period when lots of different systems were put on the market, causing headaches for many people who wanted to adopt this technology.

However, things have changed in recent years. In 2017, Mavic launched a ‘Road UST’ standard specifying dimensional and pressure requirements.

This standard was then used by the ETRTO to develop road tubeless standards that were implemented in 2019.

Mavic itself introduced the standard to its wheels and tyres in 2020.

The new tubeless road standards dictate the necessary bead seat diameter of the rim, the height of the sidewall and the shape of the rim’s central channel. Tubeless Crochet (TC) covers traditional hooked rims and Tubeless Straight Side (TSS) refers to hookless designs.

These standards act as a guideline for rim and tyre manufacturers, but there is no law forcing manufacturers to adhere to these standards. So, while things are a bit clearer, there's still a level of confusion around which tyres can be used with which rims.

Can I run any tubeless tyre with any tubeless rim?

When it comes to mountain bikes, you are mostly free to use any tubeless tyre and rim combination. You should still use some caution though because there can be variations in tyre sizes and internal rim widths that fall outside of ETRTO standards.

For road and gravel, you will need to check rim and tyre compatibility. Some brands, such as Zipp and ENVE, offer tables of which tyres are compatible with their wheels.

This is particularly important when using a hookless rim. If you use an incompatible tyre with a hookless rim, you run the risk of the tyre rolling off the rim, potentially causing injury or even death.

Can I run tubeless tyres and rims with an inner tube?

Yes, you can run tubeless tyres and rims with an inner tube without issue.

Many tubeless-compatible rims are designed to be used with an inner tube, so you can repair a puncture that sealant alone wouldn’t fix.

The only thing to bear in mind is that you must use a compatible, tubeless-specific tyre if your rim is hookless.

How to fit a tubeless tyre

We’ve got separate guides on tubeless setup for road bikes and mountain bikes, but here are the basics for setting up your wheels tubeless:

- Fit appropriate tubeless rim tape according to manufacturer guidelines.

- Insert tubeless valves through rim tape and tighten down the retaining nut.

- Work tyre onto rim, one bead at a time. If you’re pouring sealant into the tyre rather than injecting it through the valve, do it before pushing the second bead into place. If you’re injecting it through the valve, remove the valve core first.

- Inflate tyre. Depending on your rim and tyre combo, your energy levels and the alignment of the planets, this might work with some vigorous pumping of a track pump. If not, you’ll need a tubeless inflator or a compressor.

- Give the wheel a shake so the sealant can coat the inside of the tyre or, better still, head out for a short ride around the block.

What happens when I puncture a tubeless tyre?

Overall, you should experience fewer punctures with tubeless. The beauty of the technology is that small punctures are healed by sealant as you ride, sometimes without you even noticing.

Larger punctures or slashes require more intervention. Your options are:

- Attempt repair with a tubeless tyre plug kit

- Remove the tubeless valve from the rim and install a standard inner tube

We've got a separate guide on how to repair a tubeless tyre.

Is tubeless worth the hassle?

It depends. For mountain bikes, it’s an unequivocal yes. For gravel bikes it’s a yes, assuming you want to get the best out of your bike and you do actually take it off tarmac.

For road bikes, it’s a yes if you want the performance benefits or you suffer a lot of punctures, but the differences are less stark.

At BikeRadar, we’re broadly pro-tubeless, but we recognise it’s not for everyone and we certainly wouldn’t recommend it for a bike that’s used infrequently because the sealant will simply dry up.

Tubeless tyre tech glossary

- Bead: Outer edge of a tyre that sits against the rim (a tyre has two beads). Tubeless beads are made from strong materials such as Kevlar to resist stretching

- Bead hook: Protruding lip at the upper inside of the rim walls that helps hold the tyre bead in place (a hooked rim has two bead hooks)

- Clincher: Standard bicycle tyre design with a horseshoe cross-section and beads that push into the rim under pressure. Tube-type and tubeless tyres are both types of clincher

- Hookless rim (or Tubeless Straight Side (TSS)): Rim design that omits bead hooks

- Sealant: Liquid poured into tyre or injected through a valve that aids sealing and heals small punctures

- Tubeless Crochet (TC): The ETRTO / ISO standard for a hooked rim

- Tubeless inflator: Device to aid seating of tubeless tyres. Can be integrated into a pump or an entirely separate canister-style unit

- Tubeless-ready: Designates components suitable for tubeless but means different things to different brands. 'Tubeless-compatible' is similar

- Tubeless tape/rim tape: Tape applied to the inside of the rim to seal spoke holes and rim joins

- Tubeless valve: Valve that fits through the valve hole in the rim and is secured with a nut to form a seal. Commonly Presta-type, but Schrader also available

- Tube-type: Designates tyres designed to be used with inner tubes and not to be run tubeless

- Tubular: Traditional tyre design that’s glued or taped to a dedicated rim type

- UST: Mavic’s Universal System Tubeless standard. A number of tyre makers produce UST tyres, but only Mavic and Mavic’s licensees produce UST rims