Last year, Polygon and Marin released two bikes, which looked very different to anything we’d seen before. The Marin Wolf Ridge and Polygon XQUAREONE EX rocked the boat with their innovative approach to rear suspension.

Both brands outsourced the back-end to a company called Naild, whose “R3act 2Play” suspension system promised unparalleled pedalling efficiency and sensitivity, using a sliding suspension element and a very lightly-damped shock.

Since then, Polygon team riders Tracey and Mick Hannah have been riding a conspicuously camouflaged downhill bike on the World Cup circuit. It too uses the distinctive suspension layout.

Mick piloted his to a very close second at last year’s World Championships in Cairns, Australia — narrowly pipped to the top spot by Specialized rider Loic Bruni. In the same race, Tracey finished third despite a considerable crash.

Recently, I had the chance to ride that very bike – albeit a less camouflaged version — and it is now available to buy. Before we get into how it rides, here are the juicy technical details.

Suspension explanation

The Polygon XQUAREONE DH boasts 218mm of rear suspension travel, driven by a downhill-focussed version of the R3act 2Play system. That means it has slightly less anti-squat than the all-mountain system, yet Polygon claims it “can also be pedalled back up a majority of trails.”

Whether you’d want to do that on a downhill bike is another matter, but pedalling efficiency is clearly high up the list of design considerations.

The carbon-fibre mainframe is designed by Polygon, while the rear swingarm (also carbon) is supplied by Naild, but is specifically designed to work with this bike. The rear swingarm — or strut — slides up and down on a large, cylindrical stanchion, using a pair of large bushings with a seal at the base of the strut.

The stanchion, in turn, pivots on a pair of bearings which connect it to the mainframe, just in front of the chainring. The motion of the strut is controlled by this stanchion, along with a pair of short rotating links that connect it to the mainframe higher up.

These links also provide all the back end’s lateral stiffness — the strut would otherwise be free to rotate on the round stanchion. The suspension is controlled by a trunnion-mounted Fox Float X2 shock with a very light damping tune.

Friction is an obvious concern with a sliding element. But when I removed the shock, the system moved with remarkably little friction, even when a side-load was applied on the swingarm.

Polygon XQUAREONE DH9 geometry

Whatever the suspension does, it’s the geometry that defines the ride more than anything else.

The XQUAREONE DH offers a four-size range, from small to XL, with reach figures from 400mm to 475mm.

The bottom bracket is moderately low for a bike with so much travel, at 351mm, and the rear-centre is similarly middle of the road, at 441mm.

Polygon XQUAREONE DH9 specs

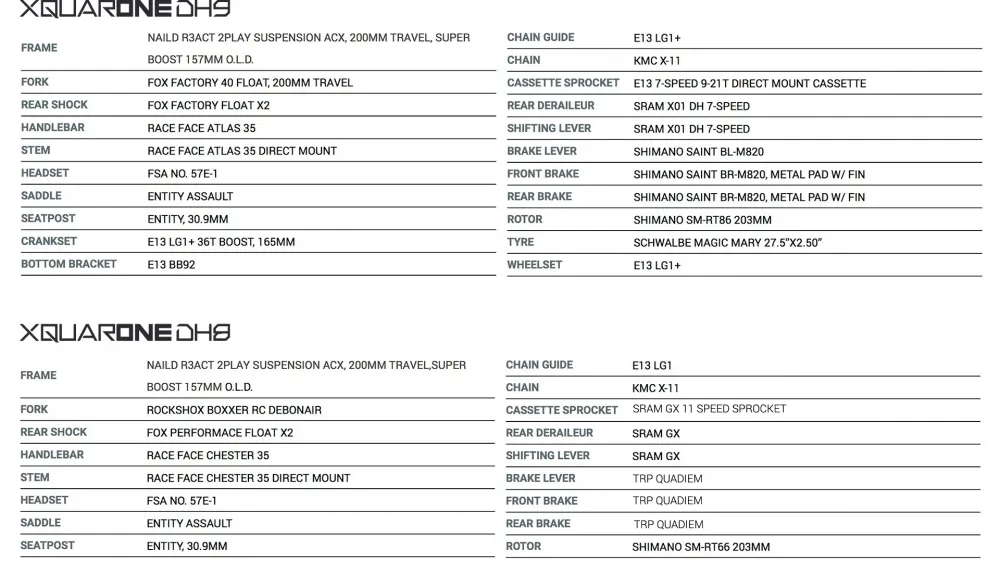

The top-spec model, the DH9, comes equipped with a Fox Factory X2 shock, Fox 40 Factory fork (with its four-way adjustable Grip 2 damper), and Shimano Saint brakes. E*Thirteen supplies the cranks and wheels, which are shod with huge 2.6in versions of Schwalbe’s Magic Mary DH tyre.

The more affordable DH8 uses a Fox Performance X2 shock, RockShox Boxxer RC fork and TRP Quadiem brakes.

I rode the top-of the range DH9, which will retail for $6,399 / €6,399. The DH8 costs $4,999 / €4,999.

Polygon XQUAREONE DH9 ride impressions

Before disaster struck (more on that later), I got to ride the XQUAREONE DH on the steep and rocky Glencoe downhill track. It’s just a stone’s throw from the more famous Fort William World Cup course, and just as technical.

The main thing to report is that the suspension does its job in a rather unusual way. For starters, yes it does pedal well. I wouldn’t like to climb on it, but for a downhill bike the pedal response is superb.

More importantly, when it comes to ploughing through boulder fields and braking bumps, the Polygon is even more impressive. The rear wheel tracks rough terrain very well indeed. It’s striking how little it hangs-up on larger bumps, and within a couple of runs I learned to drop my heels and let the suspension do its job.

Unlike the Marin Wolf Ridge, which uses its own version of the R3act system, I didn’t notice any issues with frame flex or shock binding. Nor did I perceive the pedal-kickback to be excessive during my short test.

Axle Path pondering

As an aside, it’s often said that a rearward axle path helps a bike to avoid hanging-up on larger bumps, because the wheel can move back and out of the way of bumps.

The theory is that by moving backwards relative to the bottom bracket, the wheel effectively hits the bump more slowly, thereby reducing the impact. Interestingly, the R3act system has an almost vertical axle-path, yet it seems to hang up very little indeed.

This surely is related to the lightly-damped shock, but according to Naild’s founder, Darrell Voss, the vertical axle-path minimises the time the wheel spends in contact with the bump, and therefore minimises the energy lost.

Personally, I think that in the case of bikes without an idler pulley, a rearward axle path is not necessarily desirable, because chain growth caused by a rearward axle path introduces additional pedal kickback into the system.

Damping dilemma

However, it’s not all roses with R3act. Because of the minimal compression damping, the shock needs to be run with a very high spring rate (just 20–25 percent seated sag). This makes for a less-than-settled feel on steep sections with large compressions or holes.

The reach on the XL bike (475mm) is shorter than I would like, and, at 190cm tall, the maximum bar height wasn’t quite high enough for me either. This certainly contributed to this feeling of instability in steep sections, but the suspension setup is also a factor.

Voss recommended running the rebound damping pretty much fully open on the Fox Float X2 shock. After some healthy scepticism and much debate, I agreed to try the bike setup as he recommended. While the suspension did track terrain brilliantly, and it was far less of a bucking bronco than I had feared, it still didn’t feel as settled and predictable as I’d like, especially over the larger features and steep sections.

I had a spin around the car park on Mick Hannah’s bike to see how it compared. It was set up with a very firm spring rate (roughly 20 percent seated sag with my 89kg), but the rebound was far slower than mine. The suspension barely over-shot the sag point after rebounding, indicating a slower setup than I would normally run.

Naturally, I was keen to test the bike with a slower rebound setting, but this was not to be.

Coming up short

On my third run of the track, I landed a little short on a large step-down jump, landing on the smooth, rounded knuckle in-between the downslope and the flat section above. The heavy landing was accompanied by a loud crack, which sounded like a large bolt sheering.

After coasting to the bottom, I noticed a huge crack on the down tube. That was the end of my testing.

The first thing to do was assess the level of impact which caused the frame to break. The fork had used around 175mm of its 200mm available travel, while the shock had used 72mm of its 75mm stroke. Neither front or rear had bottomed out, so why had it cracked? This is what Polygon says:

Polygon’s response

I asked Zendy Renan — product development manager at Polygon Bikes — about the cause of the frame failure.

“After the CYT scan and in-depth investigation at sample production line, (as was our prediction during the press camp) the cracking is along the mould clamping area, and the workers likely over sanded those clamping lines (they try to make it smooth) resulting in the wall thickness in that area becoming super thin and creating a structural issue.

So the concern for us is more on the Quality Control side and the procedure issue on the factory floor. But we've worked very closely with the factory to improve the control of the procedure, and to prevent this issue happening again we basically modified the procedure.

As an additional precaution, we also increased the length of 3K carbon bonding layer (the inner layer that works as a base on mould clamping) in every frame size, just to increase the safety factor — to make sure it’s still safe even if it is [sic] somehow it is over-sanded again.”

In other words, according to Polygon all the bikes which will be sold to the public will be structurally different to the one which I rode at the press camp at the end of May. They say my frame broke due to a manufacturing/quality control defect (over-sanding), which is more likely to be a problem on the Xl size, but which has now been addressed by the factory, and insured against with a longer inner layer of carbon in all frame sizes.

So hopefully, I broke a frame so you don’t have to.