Frame manufacturers typically have to slice frames open in order to examine internal structural details but German direct-to-consumer company Canyon Bicycles will soon begin using a custom built, non-destructive CT scanner that will lend valuable detail while also leaving the test subject wholly intact.

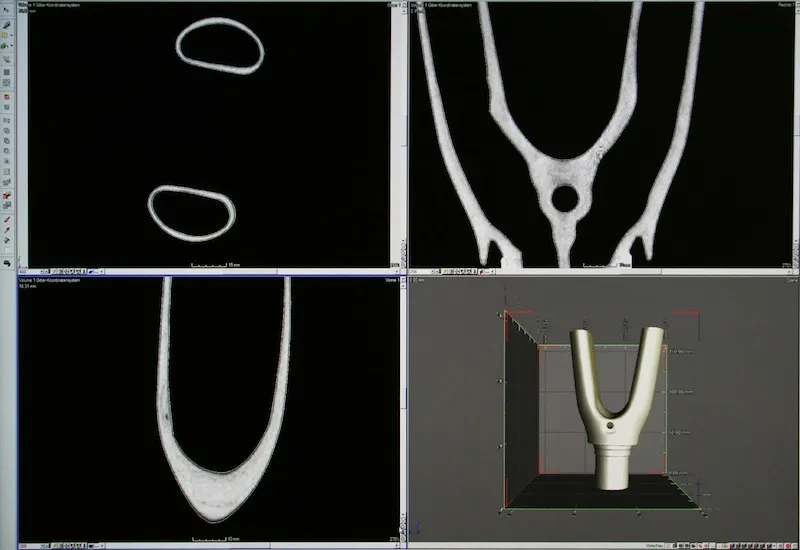

Computed tomography essentially takes a series of X-ray 'slices' of a subject, which are then stitched together to form a highly detailed, 3-D structural model that can then be analyzed and manipulated on a desktop computer — sort of like slicing a loaf of bread to determine where the raisins are. Resolution is said to be on the order of a millimeter or so.

Canyon have only just begun using the new machine a few weeks ago but plans on integrating the technology into quality control and product development. “This brand new acquisition represents a new benchmark in the cycle industry and is at the same time a further expansion of our pioneering role in that industry," said Canyon CEO and founder Roman Arnold via press release.

Canyon Bicycles recently took delivery of a new CT (computed tomography) machine that will be used for non-destructive quality control and product development

Canyon say the results compiled from these tests will be used to conduct further studies. For example, they say, the X-rays could help to analyze the possibility of reducing the weight of a product whilst at the same time increasing its strength.

Canyon plan to use CT scanning to evaluate carbon and aluminum frames, as well as carbon fiber components such as the company's forks and seat posts.