Technology that originated in bicycle frames looks set to aid the automotive industry in its pursuit of more efficient vehicles thanks to a new project headed up by Caterham Cars.

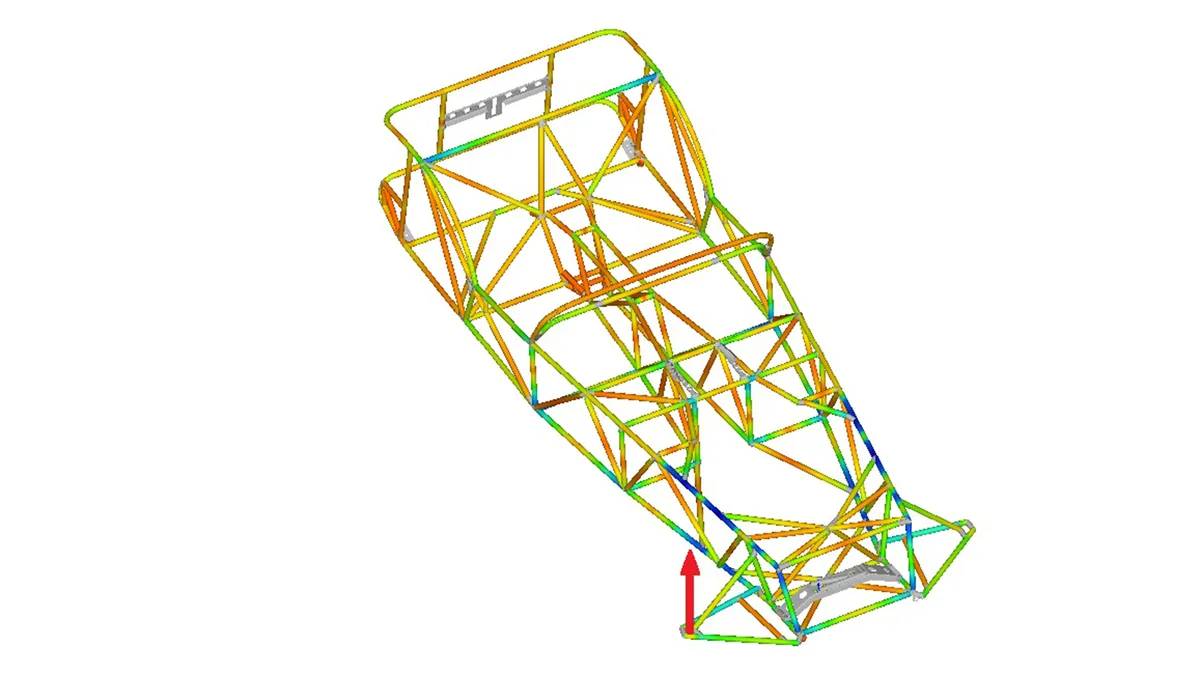

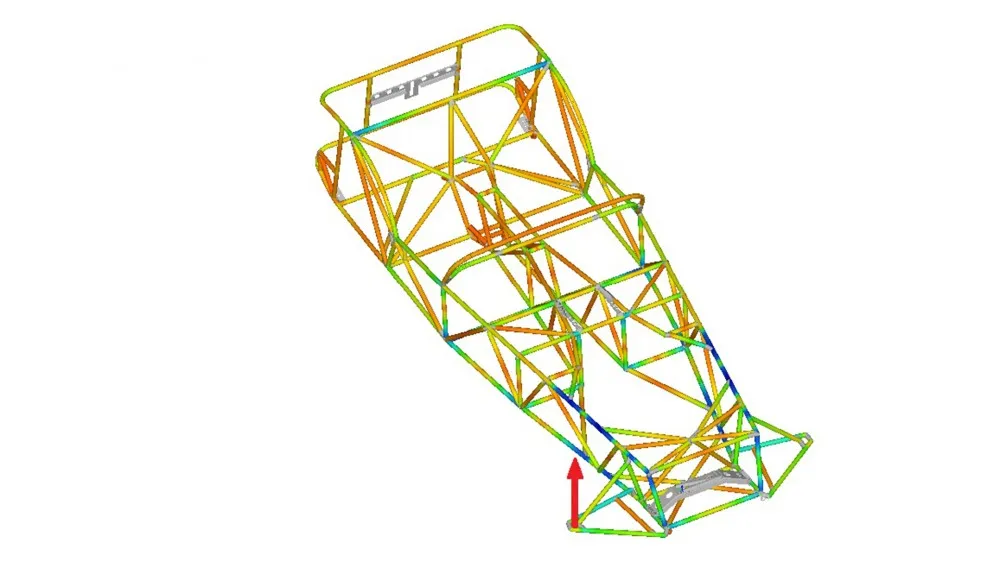

Caterham has teamed up with tubing manufacturer Reynolds, and computer-aided engineering consultancy, Simpact Engineering, in a project that will see development of the world’s first double-butted space frame chassis.

Related: Reynolds tubing handmade bikes gallery

The project, which borrows technology proven from bicycle frames, aims to prove the viability of butted tubing for use in automotive chassis.

Patented back in 1897 by English firm Reynolds, butted tubing was originally developed for use in bicycle frames. Essentially, butting allows for tubes that feature different wall thicknesses throughout – it’s a way of reducing weight from a tube without losing significant amounts of strength.The technology is now commonplace in bicycle frames but remains remarkably little used in the automotive world.

Caterham aims to drop 10 percent of the total weight from a regular Seven frame, thanks to the use of Reynolds butted tubing

Caterham intends to make use of double-butted tubing in a chassis of a prototype version of its longstanding lightweight sports car, the Seven. The goal from all this added butting is to create a chassis that is 10 percent lower in overall weight than the existing space frame design. Reynolds will provide the tubing technology for the initiative, Simpact will conduct the virtual analysis and testing to fine-tune a chassis design and Caterham will build the first prototype car.

Simon Lambert, CTO of Caterham Cars, said: “Overall, the automotive industry is under huge pressure to provide more solutions to make vehicles lighter and decrease emissions.This is something Caterham has been doing since inception more than 40 years ago, thanks to Colin Chapman’s original ethos of ‘adding lightness’, so we are well-placed to undertake experiments in this are that could benefit the much wider industry.”

Keith Noronha, from Reynolds Technology, added: “Our butted tubes have contributed to weight reduction in diverse applications from bicycle frames to NASA spacecraft projects. This project aims to prove that car designers can rethink how to use steel – a sustainable and recycleable material – while meeting challenging targets on stiffness and driveability. The Caterham Seven should be the first car to incorporate these innovative aspects.”

The Caterham Seven is of course a niche application, but Caterham and the other partners in this lightweight space frame project could soon hold knowledge key to providing a low-cost solution to the production of other lightweight vehicles.

So there you have it, people, we could well have been riding the future of car design for over a century.

What's the best material to build a bike from?