2008 Tour de France winner Carlos Sastre will start the Giro d'Italia Saturday with new Rotor 3D cranks, designed with input from himself, fellow Cervélo TestTeam riders, and team mechanics.

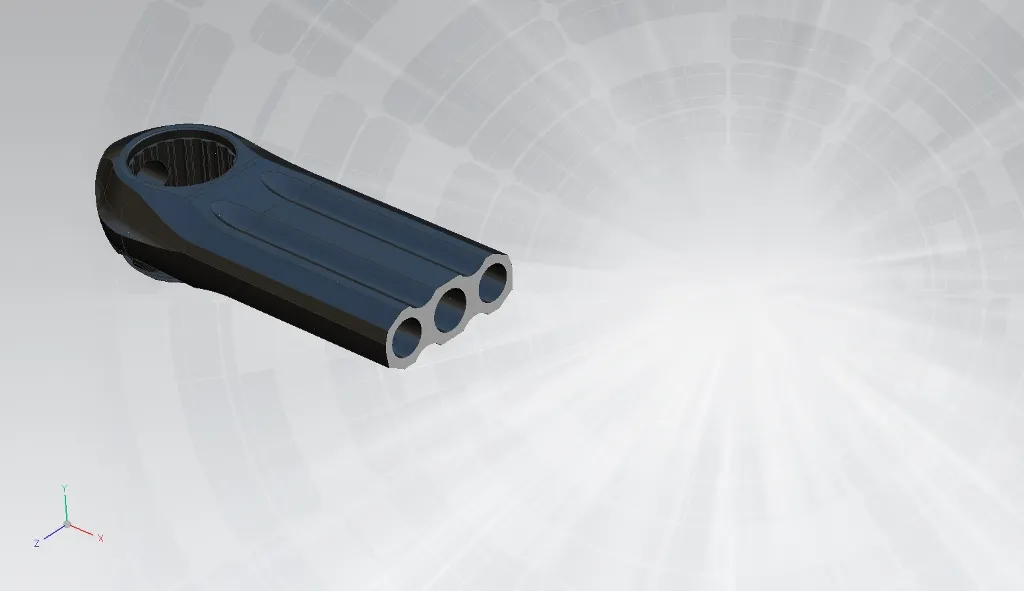

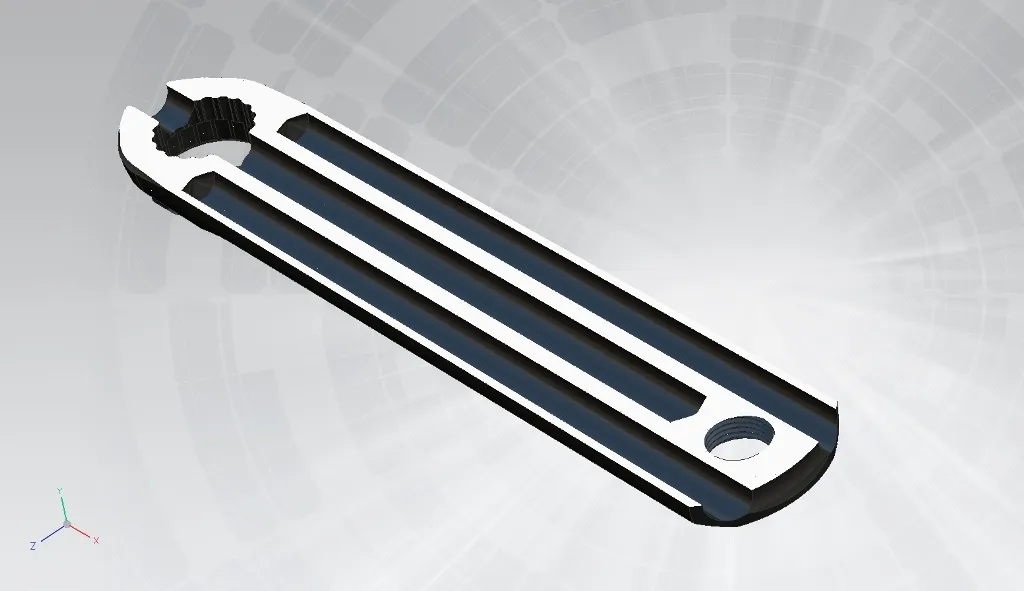

An extruded aluminium bar is CNC machined with three drilled holes through the length of the crank, which TestTeam engineers call the Trinity Drilling System. The result is a unique triple hollow crank arm, removing excess aluminium in the core while still maintaining the structural strength of the crank.

“We have a four-step protocol for product development with the TestTeam,” explained Damon Rinard, Cervélo TestTeam Race Engineer. “A partner -- in this case Rotor -- develops and tests the proposed new product. We then review it and check the in-house data, testing it in different riding situations.

"Then the Cervélo TestTeam mechanics install it and the riders try it in training; both provide us with their feedback. Once it’s been approved at these three levels, the product is then available for the fourth level: use in races,” he added.

According to Rotor, this new system has significantly improved the Hollowminum technology they developed for their Agilis Evo cranks.

"We still do not have a production date; we will decide along the Giro," Rotor marketing manager Curro Nieto Rozalén told BikeRadar. "Think September, just after the (trade) shows." No official weight or pricing was provided.

A special limited edition version of the product, with pink stripes along the crank (in a nod to the Giro) has been created for Sastre, with a special symbol that the Spaniard contributed, etched with his name.

For more information, visit www.rotorbike.com.