Back in November, BikeRadar reported on a drivetrain efficiency study by Friction Facts, and our relationship with the component tester continues to bear fruit, with this instalment investigating the efficiency of a conventional chain drive vs a toothed belt drive. Which is faster? Well, that depends.

The Gates Carbon Drive toothed belt drive has proven – especially in commuting and singlespeed circles – to be quiet, practically maintenance free, and remarkably smooth. It's also lightweight, reliable, and, because there's usually no lubricant required, everything stays clean.

But is it more efficient than a conventional chain drive? According to Jason Smith at Friction Facts, the answer is no. By his measurements, a conventional chain drive consumes 2.92 watts on average, while the belt eats up 3.93 watts. Although the difference is just 1 watt – not enough for most people to care – this works out as a substantial 34.6 percent.

That data does have some caveats, though. While the chain drive was tensioned to a typical 2lb, Gates recommends a much higher preload tension of 85lb in order to prevent slippage under load.

"The efficiency differences of the installed systems are obviously good to know for track racers and any rider who has often wondered about the efficiency of the Gates CDS compared to a chain drive," Smith told us. "However, I don't feel the results are surprising. As installed per the manufacturer's guidelines, the belt drive is fairly less efficient than the traditional singlespeed chain drive."

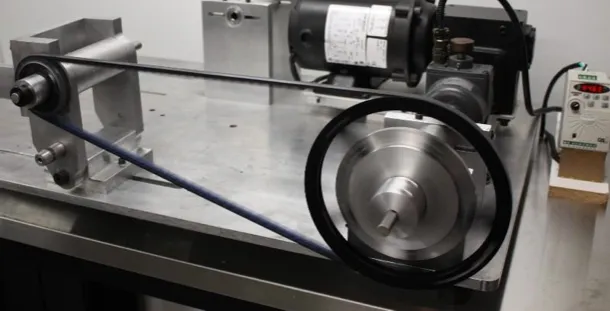

The Gates Carbon Drive during testing

Out of curiosity, Smith also ran the tests with zero preload, and it's here that the results get really interesting. The chain drive exhibits almost no friction when there's no preload applied, while the belt still eats up 1.73 watts.

Smith noticed that the slope of the two lines wasn't equal with respect to increasing applied load, though – in other words, the chain generates more friction than the belt with increasing applied load. Smith calculates that the crossover point falls at about 208 watts in terms of constant pedaling output, and the belt's advantages only increase from there.

So what, you ask? Good question. Most recreational – and even most enthusiast – riders aren't likely to notice much of a difference. However, top level track racers might certainly be interested in reducing frictional losses, given their much higher power outputs and the fact that races can be won or lost by hundredths of a second.

The standard Gates installation protocol means that even with the system's shallower slope in terms of generated friction versus applied load, the 85lb preload is simply too much to overcome. However, if one were to theoretically supplement a zero-tension Gates system with a lower roller to prevent skipping on the cog, it's then possible that track racers could benefit from a toothed belt drive system.

"The unexpected portion of the results becomes apparent when the efficiency of the belt itself is analyzed in an apples-to-apples tension comparison to the chain, without preload," Smith said. 'These results show the belt becomes more efficient above 208 watts."

"These findings will hopefully open the door to new drivetrain concepts, which would be able to take advantage of the belt's inherent high efficiency for power transfer, but without the efficiency-robbing preload requirements."

Additional details – and the full test report – are available via free download at Friction-Facts.com.