Who doesn’t like a deep-section rim to make you go faster, but have you considered that your spokes may be slowing you down unnecessarily? DT Swiss certainly has in a recent patent we discovered.

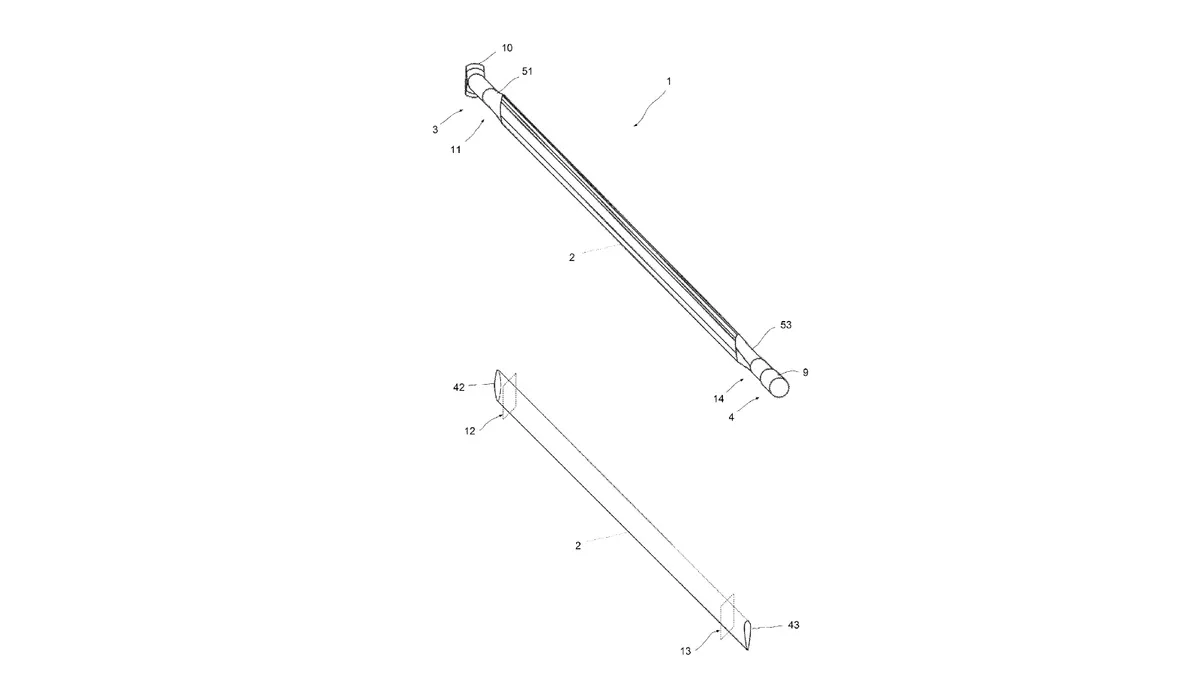

High performance wheels often come with bladed spokes, but usually these simply use either a flat or elliptical profile. The DT Swiss patent, filed on 14 June 2017, describes using an actual aerofoil profile to “markedly reduce aerodynamic drag".

A variable profile spoke

There are a few interesting things that are going on here. Some special consideration has to be made when considering the drag of spokes because their movement consists of both a rotational component (your wheel spinning) and a translational component (your bike moving forwards).

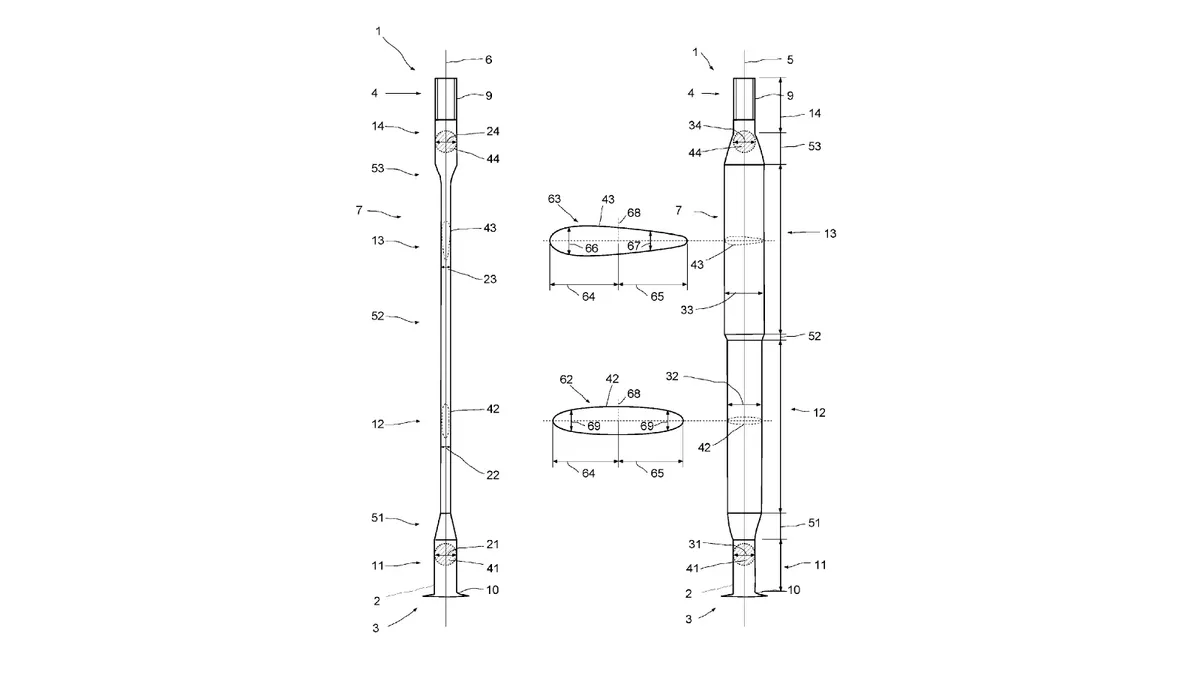

As a result, DT Swiss suggests using a symmetrical elliptical profile at the base of the spoke by the hub, which morphs into a tear-drop profile moving towards the rim.

That can either be applied continuously or with a step between different profiles. DT Swiss also mentions that the base of the spoke can be smaller to save weight, and the end more profiled for better aero performance.

The science

Let’s get into the reasons for this.

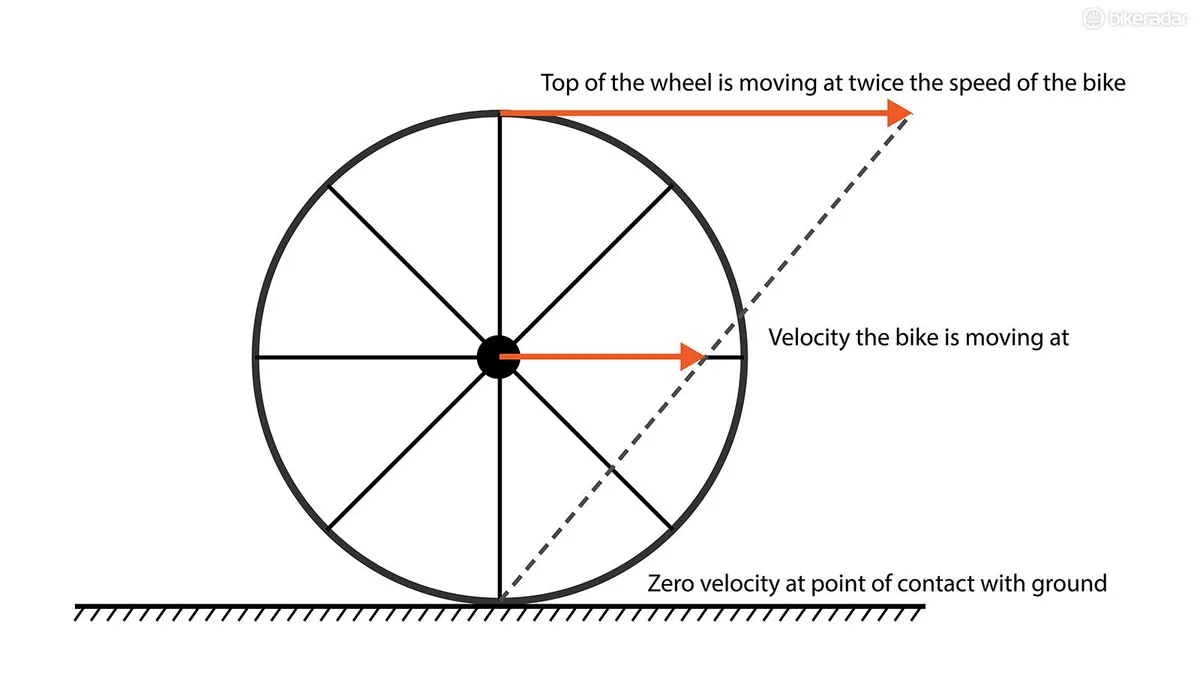

If you consider a rolling wheel, at an instantaneous moment, the bottom of the wheel that is touching the ground is moving at zero velocity relative to the ground.

On the other hand, the top of the wheel is moving at twice the speed you are moving forward (relative to the ground). There’s a linear increase in velocity from the ground to the top of your wheel that each point on the wheel at a given height is experiencing.

(The velocity i.e. speed and direction, varies slightly for the spokes that aren't vertical due to the additional effect of the rotation of the wheel that sees the spokes move in a different direction to the forward motion of the bike, but the analysis below ignores this for simplicity)

In the middle, at the hub, that velocity will equal the speed you are actually travelling on your bike.

Considering the velocity is important because aerodynamic drag increases as a square of velocity i.e. if you double your speed then drag will increases four times. That means that the 'fastest' spokes at the top of the wheel will benefit the most from an aerodynamic profile.

However, we also have to consider the rotation of the wheel. The top spokes above the hub are facing forwards, but the bottom half of spokes reverse direction and 'face backwards' as the wheel rolls round.

A directional tear-drop shape is aerodynamically efficient when moving in the right direction, but less so when the airflow is reversed — and this is the thinking behind DT Swiss’ patent, changing the profile along the length of the spoke.

Remember that close to the ground the velocity of the spoke is low, and drag is low as a result. While a teardrop profile won’t be the most efficient, the increased drag is relatively negligible, relative to the reduced drag when the spoke is at the top of the wheel.

As we approach the area around the hub the velocity gets higher for both the forward facing and backward facing spokes.

In this case it makes sense to stick with a non-directional and symmetrical elliptical profile, which provides the best efficiency in both spoke orientations.

Finally, as we approach the top of the wheel, the velocity is substantially larger than at the bottom of the wheel, which is where the directional tear-drop profile works its magic to reduce the drag experienced by the spoke.

Basically, this is a balancing act, and while the teardrop increases drag slightly at the bottom of the wheel, this is more than compensated by the non-linear nature of drag, meaning the profile can be optimised for forward motion at the top of the wheel.

Conversely, around the hub the velocity differences between top and bottom spokes are less pronounced, so it’s important to have a profile that works well in both directions.

Will it happen?

We would assume that it’s a when rather than if because this would be a relatively easy idea to implement from a manufacturing standpoint. We'd also assume that because the idea has a patent application it provides some measurable benefits.

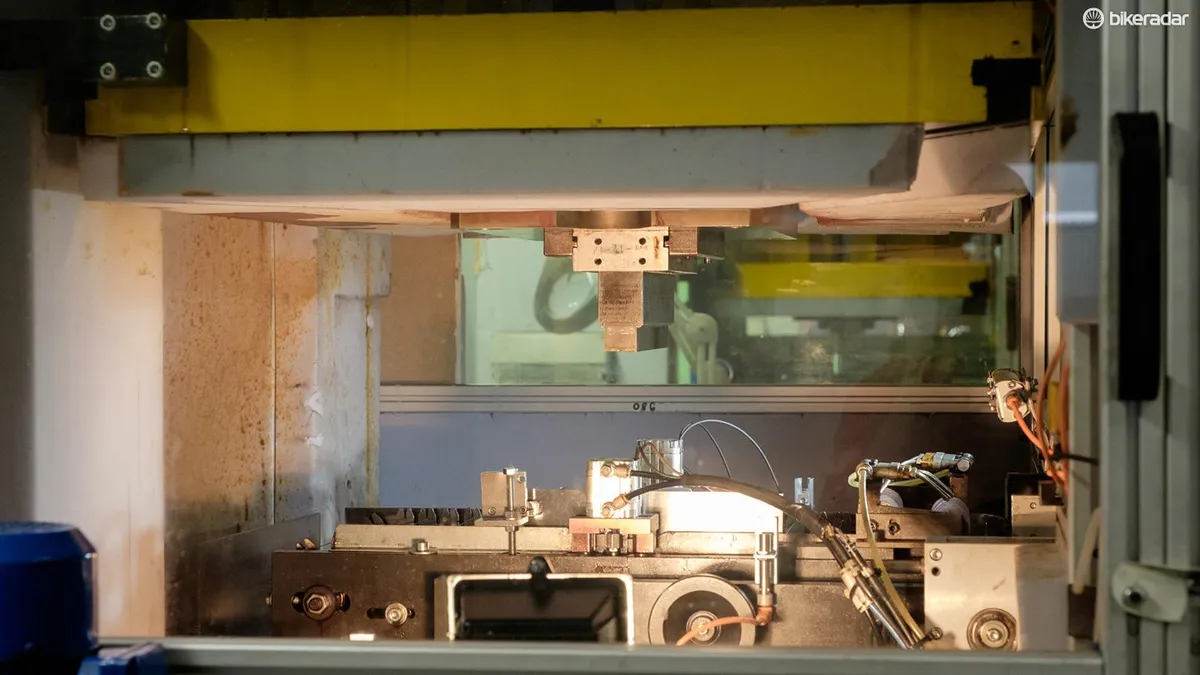

Currently DT Swiss spokes are simply stamped flat to blade them. Implementing this would essentially involve a change in the die used to form the profile, slotting in easily into the existing manufacturing processes.

While this patent outlines the theory, we assume that DT Swiss will have to do some more rigorous analysis and testing to define the best profiles and how to vary the spoke profile along its length, but we are very interested to see if this technology will show up in the future.