It’s not often that we get to try something genuinely new. The bikes we review are most often evolutions of existing designs, and most of the componentry we test aims to be lighter, stiffer, or cheaper than its predecessors, but it’s rarely fundamentally different. When we first caught wind that Rotor was planning to enter the groupset market we weren’t sure what to make of it. The market is dominated by Shimano and SRAM, with Campagnolo bringing up the rear. Rotor's UNO group is fundamentally different, in that it is hydraulically actuated. This isn't completely uncharted territory, however. The German company Acros already makes a hydraulic mountain group.

Who, what, where and why?

On the face of it, introducing hydraulics to shifting might seem like needless complexity. Cable shifting does, after all, work quite well, and for those that don’t want to maintain a cable system, electronic shifting offers fit-and-forget adjustment and less onerous installation requirements. (Electrical wires don’t mind going round tight bends.)

Rotor product manager Lars Janssen says the UNO groupset combines the best features of mechanical and electronic systems. It’s designed to offer a degree of mechanical involvement, low weight, low maintenance, easy cable and hose routing, and to be a natural match for disc brakes.

By moving the indexing mechanism to the derailleurs, UNO aims to ensure consistently accurate shifting. At the lever end, all you’re really doing is operating a hydraulic switch, meaning that the shift quality isn’t reliant on the hydraulics for its accuracy. As a result, Rotor anticipates extremely long service intervals – you’ll likely need to bleed the system after shortening hoses, but once set up it should work properly for years without intervention. In a similar vein, the braking system uses a non-water absorbing fluid (Magura Royal Blood), which reduces the need for frequent bleeding.

Rotor describes the UNO groupset as “its baby”, one its been pregnant with for six years. (This is almost a direct quote.) Final prototypes have been on the road with sponsored teams since November and Rotor has incorporated their feedback into the final product. The company is finally ready to give birth…

Details, details, details

For a complete hydraulic disc groupset excluding cranks, Rotor claims that UNO weighs just 1604g. According to its figures, this represents a saving of 10g over the equivalent SRAM Red 22 setup, 99g over eTAP, and 417g over Shimano Dura Ace Di2. Read on for details of UNO’s individual components.

Shift/brake levers

The shift/brake levers have a claimed weight of 333g (per pair) and have plenty of ergonomic detailsAvailable in two non-interchangeable versions for disc and (hydraulic) rim brakes, these have a lightweight carbon brake lever and a CNC’d aluminium shift paddle. The rubber hoods cover a fairly wide body, which Rotor says it designed for comfort based on rider feedback. Down the line, sizes may be available to suit different hand sizes. A screw allows for reach adjustment, but the bite-point is pre-set.

The UNO groupset has two completely separate hydraulic systems for braking and shifting. The former uses Magura’s Royal Blood mineral oil, while the latter employs a glycol-based fluid that’s stable from -15 to 85 degrees Centigrade.

Shifting is somewhat similar to SRAM’s DoubleTap. The brake lever is for braking alone, and all shifting is carried out with the single paddle. A small push gets you smaller cogs (or the inner chainring), while pushing through to the second position moves the chain up the cassette or onto the big ring. Rotor hinted strongly that satellite shifters may be in development too, noting that it’s relatively straightforward to tap into a hydraulic line to add additional switches.

The shift hoses are small and flexible

Hoses

Braking comes via Magura 5mm reinforced hose – pretty standard stuff. Shifting on the other hand is delivered by a flexible 3mm hose which can be routed around tight corners. It’s thin enough that it can even be fitted to frames that are designed for electronic shifting only. Weight is to be confirmed, but Rotor quotes 146g for ‘extras’, i.e. everything not included in the main components.

Rear derailleur

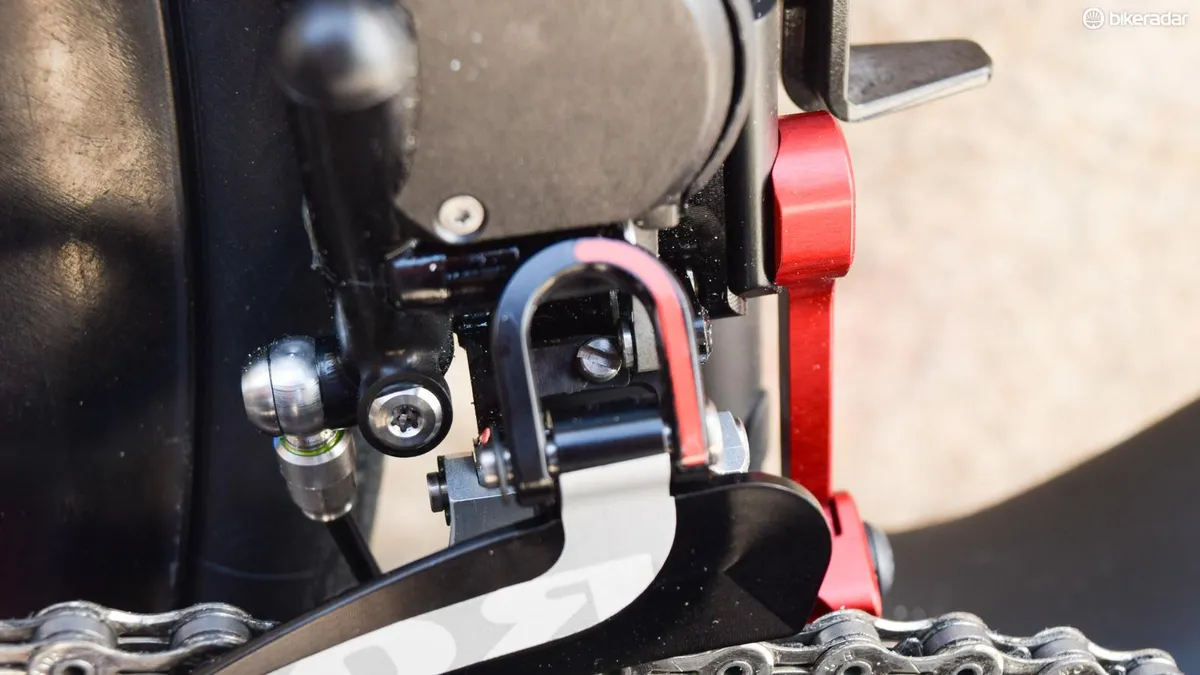

Rear derailleur set-up is more straightforward than with mechanical or electronic rear derailleursA work of CNC art, the rear derailleur is made from steel, aluminium, and a smattering of carbon on the cage. As the shifters are effectively just hydraulic switches, all of the indexing is built into the derailleurs and the jumps between cogs are permanently fixed. Because of this, there are no limit screws, and the only adjustment during setup involves turning a single bolt to align the derailleur with the cassette. We do wonder if this might be an issue in the event of a damaged hanger since there’d be no way to prevent the derailleur shifting into the spokes, but that’s likely a worst-case scenario only.

Wheel changes are made easier by the ‘return to origin’ switch, which moves the derailleur to its outermost setting (i.e. the smallest cog). In the event that the hydraulic shift hose is damaged, the derailleur can be set to any gear manually .

While the default setting allows riders to shift one gear in either direction, unscrewing the multi-shift bolt allows up to four downshifts (shifts to larger cogs) with a single sweep of the paddle.

The claimed weight for the rear derailleur is 212g.

Front derailleur

Like the rear, the front derailleur has no limit screws and relies on a single bolt adjustment. Once again, the indexing is entirely within the derailleur, and it has four positions – two for the inner chainring and two for the outer. Construction looks similarly polished to the rear, with some lovely machined details on the cage. The claimed weight for the front derailleur is 114g.

Brakes

Rotor relies on MT8 brakes from MaguraFor the calipers, Rotor has partnered with German manufacturer Magura. The disc units included with the groupset are its MT8 with UNO branding, while the rim brake is the same RT8 TT found on Cervelo time-trial bikes. Rotor is sticking with 160mm rotors only, citing heat concerns with the 140s found on many road and ‘cross bikes.

Post mount disc calipers will be shipping with the first retail groupsets, with flat mount standard ones to follow a month or so later. The claimed weight for a pair of disc brake calipers is 413g.

Cassette

Compatible with standard Shimano/SRAM freehubs (and using the same cog spacing), Rotor’s cassette is manufactured entirely in-house. It’s made up of three major sub-assemblies, with steel used for the smaller cogs and aluminium for the largest two. If you’ve got wheels with a Campagnolo 11-speed freehub and cassette these will work fine with UNO too, as the cog spacing is close enough not to matter. The claimed weight for an 11-28t cassette is 150g.

Chain

Unsurprisingly, Rotor hasn’t chose to make its own chain, instead choosing a top-end model from specialist KMC, with colour-coding to match the Spanish company’s branding. The X11SL has the latest ultra-hard DLC coating and is compatible with all 11-speed systems. Claimed weight for the chain is 273g.

What about cranks?

Rotor already makes a range of cranks for riders to choose fromAlthough the UNO is packaged as a groupset, it doesn’t actually include a dedicated crank. Rotor takes the view that different riders will prefer different models from the line-up, and of course some will choose a power meter over the standard option. Our test bike was fitted with Rotor’s latest 2INpower power meter.

Pricing and availability

A full groupset including shifters, derailleurs, brakes, cassette and chain (but excluding cranks) is to retail on the Continent at €2499, with prices for other regions to be confirmed. UNO is expected to be available with post mount calipers from July, with flat mount versions to follow around a month later.

First ride impressions

A Cervelo R3 Disc was my test sled At the launch event in Spain, Rotor provided me with a Cervelo R3 Disc kitted out with a full UNO groupset (apart from a Shimano cassette and a standard KMC chain in place of the matchy-matchy UNO version). My test ride was abbreviated by poor weather in the mountains (snow in Spain in April! Who’d have thought?) but we managed 71km and nearly 1,300m of climbing — enough to get a feel for how the groupset behaved in the real world.

Initially braking was poor, but this purely down to brand new pads and rotors which hadn’t bedded in yet. After a little use I had no complaints – the lever feel is fairly linear, and while they don’t bite as hard as say, Shimano road discs, power from the Magura calipers is certainly ample. The lever shape works well from both the hoods and the drops, and I was happy to brake with one finger from the latter.

Shifting was the real unknown quantity. Although the principle is similar to DoubleTap, it feels quite different. With SRAM you feel like you’re compressing a spring, whereas Rotor’s shift is distinctly hydraulic in feel, more akin to pulling the brake lever on a mountain bike. It takes a moderate effort to move the shift paddle to its first position, and a fairly determined one to get to the second.

At the rear, this works rather well. I did most of my ride with the multi-shift feature turned off, and there was no faltering or inconsistency. Essentially, if you can handle DoubleTap, you’ll get on just fine with this. The front was slightly less impressive. For starters, with the chain in its outermost position (big ring, smallest cog) I experienced a little rub from the front derailleur cage. With no limits or cable tension to adjust, there’s not much that can be done about this (assuming the initial indexing setting is correct, which it appeared to be). One Rotor representative did comment that the Cervélo’s relatively short chainstays were right at the limit of specs, producing a less-than-ideal chainline.

More problematically, I had persistent issues with the chain refusing to drop onto the small ring under load. In a standard mechanical setup, a powerful return spring shoves the chain off the big ring. We’re not completely clear how the Rotor derailleur compares in this respect, but it certainly wasn’t as assertive as we’d have liked, and the ramping of Rotor’s outer ring was proving rather too effective, grabbing the chain back when we wanted it to drop down.

There was plenty of opportunity to explore shifting under load (photo: Rotor)

I also found that the combination of the four-position front derailleur and the DoubleTap-style shifter arrangement wasn’t particularly intuitive. Because the shifters aren’t tied directly to the movement of the derailleur in the way that they are with a cable setup, you can’t feel what the chain is doing.

At the end of the ride I had a Rotor mechanic activate the multi-shift feature for a quick try-out. It can be set to allow two, three, or four downshifts in one go, so naturally I went for the full four. It does work absolutely fine, but it’s quite difficult to tell exactly how many gears you’ve shifted in a single sweep of the lever. There are no clicks to act as indicators, and the lack of mechanical feedback means you’d need to spend a lot of time honing your muscle memory for it to be useful.

Verdict

The UNO groupset is at once hugely impressive and slightly frustrating. It’s a beautiful piece of engineering that’s truly original in a number of ways, and which appears to deliver on many of its promises: it’s light, seemingly practical from a maintenance point of view, and it does work. Some real-world niggles need addressing though, principally relating to the front shifting. We want to spend some more time with UNO before giving a final verdict, but we will say this: if you love clever engineering and are prepared to put up with some quirks, it’s a fascinating system that’s worth your attention. It’s not perfect, but it is very, very cool.