Rotor readily pokes fun at itself in regards to the new Uno road groupset, rightfully calling it “one of the worst kept secrets in cycling.” That the group was in development may not have been in question but how exactly it works has been anything but clear – until now. We sat down with Rotor engineering manager David Martinez at the Eurobike trade show and got the full scoop on Uno’s oil-filled guts.

Martinez says that Uno will be “the lightest complete disc brake road groupset” when it eventually hits the market in spring 2016. Much of the weight savings comes from the use of lightweight aluminium alloys and liberal helpings of carbon fiber but it’s the hydraulic actuation system that ultimately puts it over the top. Rotor has yet to quote exact figures – either for pricing or weight – but low-pressure hydraulic line and oil is certainly lighter than equivalent lengths of steel cable and housing.

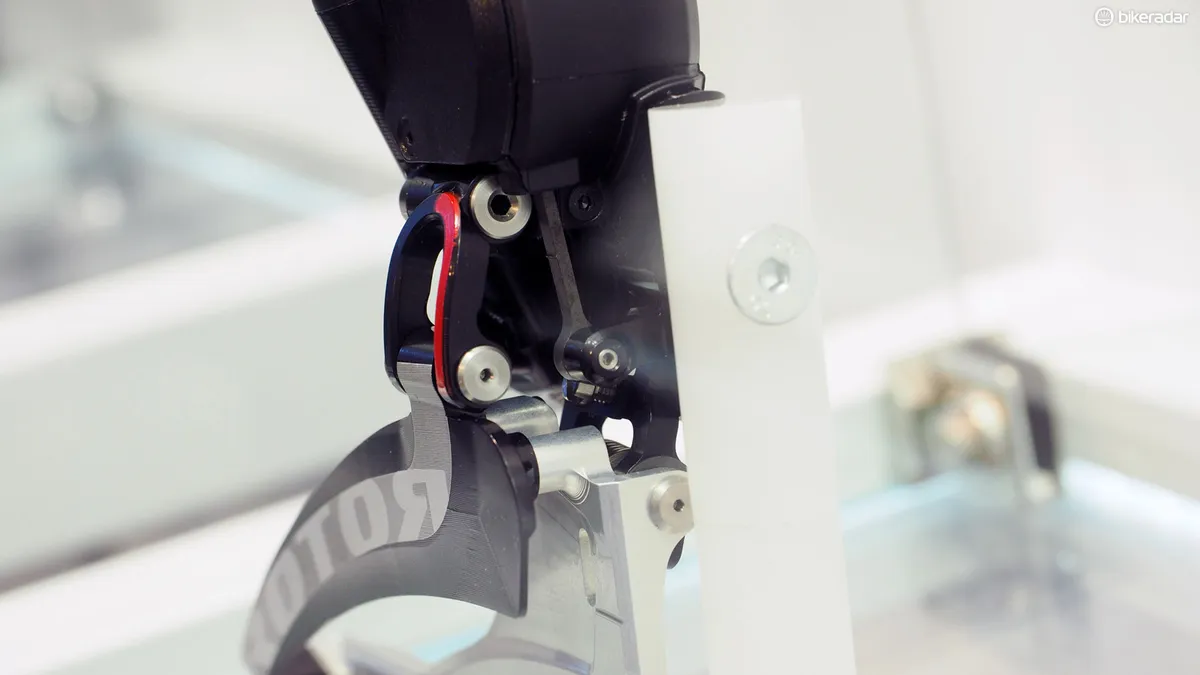

The indexing mechanisms are located in the derailleurs, not the levers

Unlike Acros’ A-GE mountain bike transmission – which uses two hydraulic lines per derailleur – the Rotor Uno setup uses just one. Each serves the same function as the cable does in a conventional transmission, moving the derailleur cage inward out back and outward up front. Strong mechanical springs handle the return motion.

Whereas conventional transmissions house the gear indexing functions in the levers, however, Uno relocates them to the derailleurs using a system called HyStep. The mechanism – at least for the rear – is somewhat similar to a geared ratchet wheel (or wristwatch internals) with discrete positions for each cog. Adjustment is apparently brutally easy, too: just set the derailleur’s adjustment ‘window’ to match up with the cassette sprocket positions, and then lock the assembly in place.

Ripped a hydraulic line or had some other sort of mechanic failure? Flick the little grey lever and you can manually position the cage at will, and then lock it into place again

Rotor has also engineered a clever failsafe device for the rear derailleur in the event of a crash or other damage. A small lever on the upper knuckle unlocks the indexing mechanism and allows users to move the cage as needed – either for quicker wheel changes or to manually select gear positions in the event of a hydraulic failure. Martinez says that individual small parts will eventually be offered, too, meaning that (at least in theory) Rotor’s derailleur will be fully serviceable and repairable, much like old Campagnolo units.

That single hydraulic line architecture will pay dividends when it comes to installing the Uno group, too. Martinez says that each line measures just 3mm in diameter – small enough that two will fit through the same access hole as a Shimano Di2 or Campagnolo EPS wire (albeit with a different grommet). As a result, Uno won’t require frame or bike companies to make any changes whatsoever to existing internal routing layouts, and the group will also install on to most current bikes.

While the hydraulic brake lines will require continuous paths for internal routing, the small hydraulic derailleur lines are just 3mm in diameter and both will fit through a single Di2 or EPS frame hole

It may be a different story with the brake lines, however, as Rotor has designed Uno to work exclusively with hydraulic rim or disc calipers, meaning full-length lines front and rear. Development partner Magura will supply the brakes in both cases, using the compact one-piece MT8 caliper for disc applications and the RT8 for rim ones. The same lever will work for either setup with a simple leverage ratio change.

Interestingly, the Uno shifter paddles operate much in the same way as SRAM’s well-known DoubleTap system: push lightly to move to smaller-diameter cassette cogs or chainrings, and push further to move to larger-diameter ones. You can upshift just a single cog per lever swing but you can downshift up to four – and if that’s too many, you can even adjust that figure down to one.

Shifter operation is very similar to SRAM's DoubleTap levers, although with a very different feel

Levers ergonomics are similar to SRAM DoubleTap with the single, large paddle being easy to reach from either the hoods or drops. However, the action is markedly different from anything released to date from Shimano, SRAM, or Campagnolo (or FSA, for that matter) with a much heavier feel and a more muted and slightly disconnected sensation since the indexing is at the far end of the hydraulic lines. That heaviness carries over to the brakes, too, which seem very positive but also require a fair bit of effort to actuate.

On the plus side, however, Martinez suggested that remote shift actuators (such as for climbing, sprinting, and time trials) are already in development, installed via simple T-connectors spliced into the hydraulic lines.

Another surprise is that Rotor plans to supply its own cassette for Uno, utilizing a machined (mostly) one-piece steel construction similar to SRAM’s latest Red 22 models. Whereas SRAM uses an aluminum backplate pressed on to the steel main assembly, however, Rotor looks to be machining the largest two cogs from aluminum and then bolting everything together.

Surprise! Rotor plans to supply the Uno group with its own cassette

Currently it’s unclear where the chain is coming from but given the manufacturing and engineering challenges entailed with such a seemingly simple component (which, in actuality, is anything but), it’s unlikely that Rotor is doing this one on its own.

Long-term durability for the Uno’s hydraulic system sounds promising. Rotor is manufacturing and assembling all of the components in Madrid, Spain but then shipping complete assemblies to Magura in Germany for bleeding and final testing. As a further sign of confidence, there will even be the same 10-year leakproof warranty as on Magura’s hydraulic disc brakes.

At least in theory, the hydraulic mechanisms should be fully sealed and protected from the elements. Ignore the clear plastic housing; it's just for show

Keep in mind that the units on display at Eurobike were still development mules, and it’s still possible that final versions will feel different. So for now, we’ll reserve final judgment on performance until we’re able to actually ride production bits on the road. Regardless, the technology that Rotor has incorporated into Uno is truly innovative – and different – stuff, and we look forward to giving it a go.