Brothers Jay and Jeremy Sycip design, build and paint lugged, TIG and fillet-brazed steel bicycles in their Santa Rosa, California workshop. Artists by trade, they've been making handcrafted bicycles since 1992, and their once-eclectic integrated stem and bars, custom racks and fenders, and townie bikes set them apart years before the current handmade craze.

The popularity of handmade bicycles keeps increasing and framebuilding brothers Jay and Jeremy brothers are delighted. Their road to success in this exacting arena wasn't smooth, but it has been fulfilling.

Jay (L) and Jeremy Sycip in their Santa Rosa, CA shop

For the past decade they have been building 150 - 175 frames per year and unlike some framebuilder who have multi-month or even multi-year waiting lists, Cycip aims to get a frame into a customer's hands in 8 - 10 weeks.

"I've noticed that people don't like waiting longer than that; it pays to communicate with the customers," Jeremy said. "Ninety percent of our orders are for TIG, which is less expensive, quick and clean. Now that we're painting in-house it helps with turnaround time and delivery."

Jeremy Sycip, brazing away at the table

A glance through the photo galleries from the recent North American Handmade Bicycle Show in Portland, Oregon reflects a trend toward handmade racks, stem and bar combos, and a flowing line that's pleasing to the eye, all Sycip trademarks. The brothers have no ill thoughts about the newbies stepping into their territory.

"There's a new surge of framebuilders, which I think is great!" Jeremy said. "It reminds me of when we first started, handing out flyers at cyclo-cross races and attending shows wherever we could. We just started having our own stainless dropouts made by Paragon Machine Works. The new-look integrated bar-stem came about because I got some close-out Tange steel tubing years ago, and it caught on pretty quick. It's cool to see others taking the same path. Doing stem and bar combos is tricky alignment-wise, but the end-result is cool.

"I bought a frame jig, fork jig and stem jigs when I first started," Jeremy added. "We still build most of our stuff here, unless someone wants something less expensive, then we buy Tange or other forks and paint match them."

The new Sycip stainless dropouts, designed by Sycip and made by Paragon Machine Works

From art school to the torch

The Philippine natives, who emigrated with their family to the United States in 1983, attended the famous Pasadena Art Center in the late '80s, where Jay, three years younger than the now 37-year-old Jeremy, studied illustration and graphics, which he graduated with in 1992. Jeremy, fascinated with transportation, studied product design for a year before dropping out to work at a bike shop. Curiously, 1966 'Batmobile' creator George Barris graduated from the Center decades earlier.

Jeremy caught the bike bug in a big way, contacting Salsa Cycles about a job. This set off a chain of connections that lead to the current Sycip bicycle building operation, including learning at the feet (and hands) of master framebuilders Albert Eisentraut and Paul Sadoff, known for his brand Rock Lobster.

The shop, a rather large space in the historic railway section of downtown Santa Rosa, was taken over by Sycip when the brothers outgrew their San Francisco space in the early 2000s. They also took advantage of the in-house powder coating equipment, which they use to paint their own and other builders' frames, forks and components. Occasionally Sycip will outsource their custom wet painting to Spectrum Powderworks in Colorado.

"Jay and I both attended the Pasadena Art Center in the late `80s," Jeremy said after giving me a tour of their facility. "I dropped out to work with Paul Sadoff of Rock Lobster in Santa Cruz. He took me in to be an apprentice.

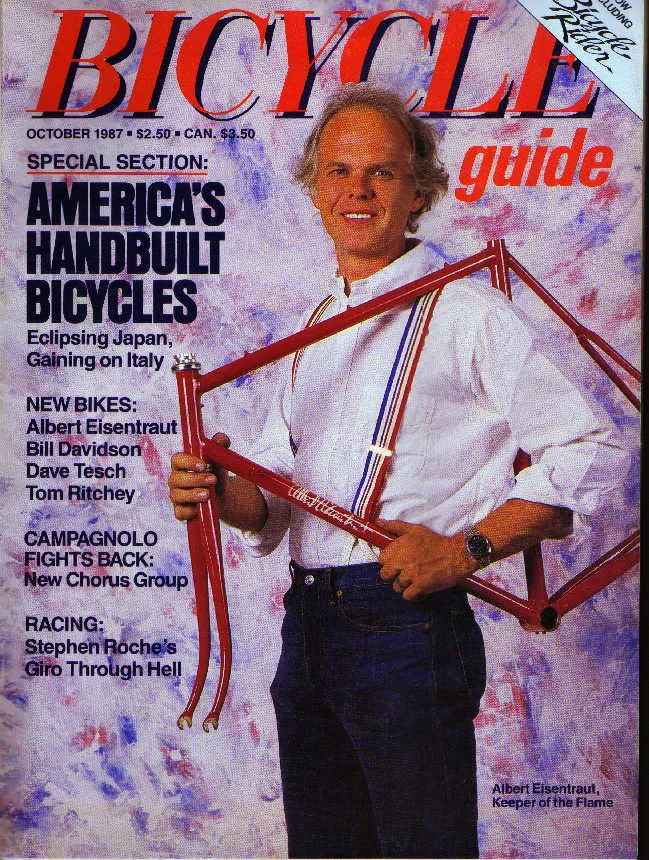

"Early on I took a two-week framebuilding class at United Bicycle Institute. Albert Eisentraut was teaching; it was his last class, so that was cool to learn from Paul and Albert. They knew their craft well. When Jay graduated from Pasadena we started our business and moved out on our own. I still did work with Paul, though, because there was so much to learn."

Framebuilding teacher Albert Eisentraut in October 1987

Eisentraut began building frames after apprenticing with Schwinn Paramount master builder Oscar Wastyn in 1959. He, in turn, shared his proficiency with many popular builders, among them Petaluma, CA-based Bruce Gordon, who still wins awards. For decades Eisentraut would travel the country and teach framebuilding seminars before fate brought Jeremy Sycip to his classroom in Oregon. Sycip explains his chain of events that lead to mastering the torch.

"I started learning more about Salsa and Bontrager after dropping out of Pasadena; I called Salsa to get a job there, and Ross Shafer referred me to Paul," he explained. "At the time Paul, who never had an employee, just apprentices, needed help, so he had me cleaning, prepping and filing dropouts; nothing glamorous, mainly that and cutting tubes.

"It wasn't until I had my own business that Paul let me do any braze-ons for him. It took him awhile to trust me with a torch! I worked for Paul for four years, into the mid 1990s. Working for Paul was a learning process; I wasn't paid. I was a true apprentice. Jay worked at a cafe to make money to support our first shop in Fremont, California," Sycip added.

The first Sycip frame, a handpainted lugged beauty

With Jeremy as the metal worker, Jay's role has been taking care of graphics and marketing. According to Jeremy, his younger brother has a keen eye and a good sense of colours.

"One of the things that got our name out there quickly was Jay's hand painting each frameset, like flowers and stuff clearcoated over," the elder Sycip said as he showed my Sycip frame number 1. "People liked it, but it got too time-consuming, and that means a pretty expensive frame."

Details of the beer-tap handled Sycip townie, with stainless headbadge

The casually hip graphics and unique colours brought attention to the brand, and it was only a matter of time before a custom headbadge was developed, sometime in the late 1990s.

"Headbadges came out in the late '90s; we wanted something nicer than a decal," Jeremy said. "A friend of ours at Pasadena came up with the Sycip logo."

And for several years now, customers still like the subtly quirky Sycip brand, many who return to buy another model once they start with a mountain or road bike. Sycip's peak employee count was six people. Currently there are four, including Daniel, the full-time painter. Jocelyn, Jay's wife, does the books and is the glue that holds everything together.

A Sycip road fixie with disc brake at the crank, not something you se on the streets everyday

A typical sight in the Sycip booth - photographers capturing the unique fixie with integrated bars/stem, custom powder coated rims and topped off with a leather Brooks saddle

"All the bikes we took to Portland were built three weeks prior; I think our ideas come about better that way," he said with a chuckle. "The beer-tap-handled shifters bike and the disc-brake fixie got the most attention in Portland. We just wanted to show off some different stuff for a show."

The beer-tap handled Sycip in Portland, with custom steel racks and rear wheel webbing

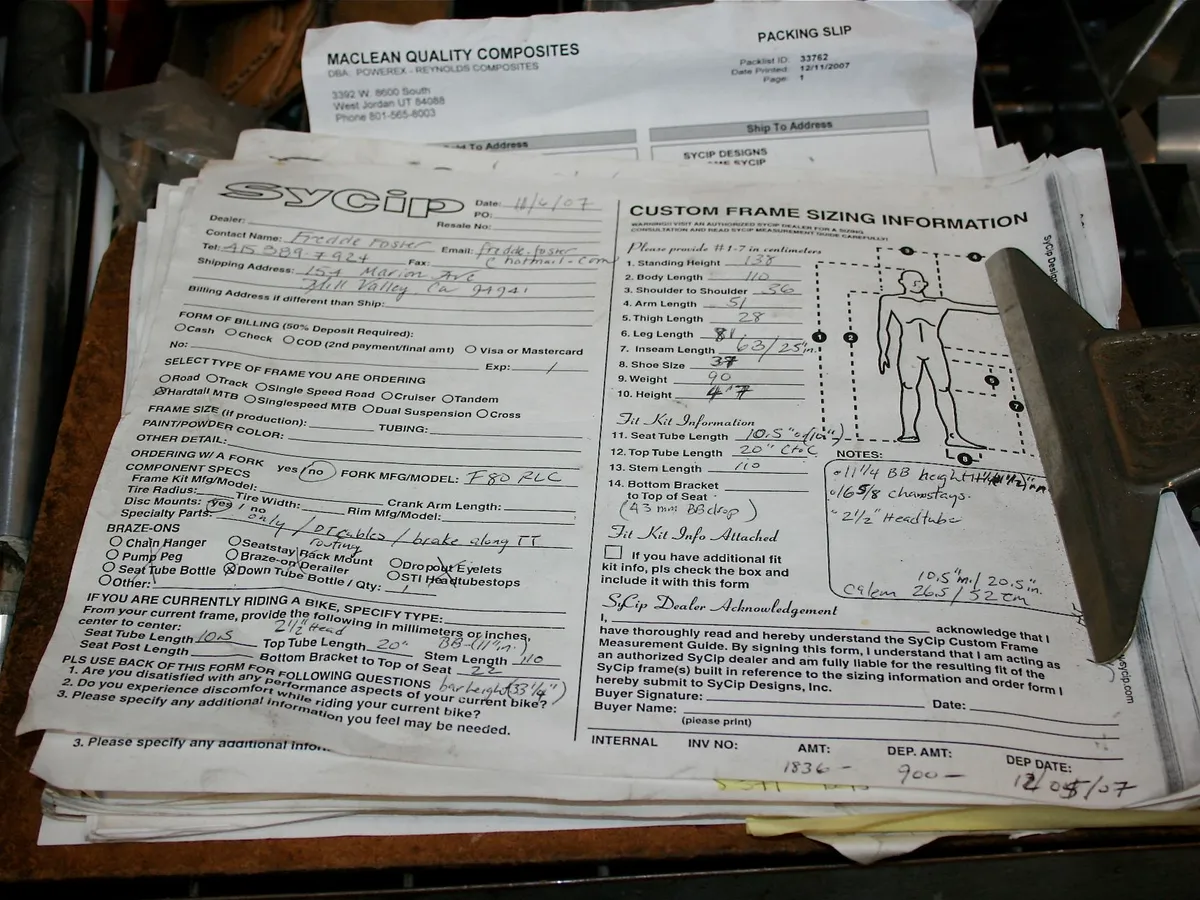

With a steady flow of frames built and painted in their workshop, the Sycip brothers still encourage tours and the occasional sizing session if a customer needs a helping hand.

"We like giving tours and giving visitors a chance to see what we do, how we do it," Jeremy said, waving his hand toward a row of show bikes and a Serotta sizing cycle in the corner. "We're totally open to having people come in for a sizing session if need be. Jay and I both share the sizing duties.

"There was one time when we tried selling through dealers only, but it wasn't profitable, so we sell directly in addition to having a handful of dealers. We don't undercut or anything, just make bikes available, especially to those from the greater San Francisco Bay area," he added.

Pennies brazed to the seatstay caps, a Sycip signature

In the cut-throat world of high-stakes bike selling at the top level, where the limited oxygen is fought over by Trek, Specialized, Cannondale and Giant, Sycip has also spawned its share of master framebuilders developing a flair and style all their own, even if they are two and three times removed from Wastyn and Eisentraut. Former Sycip apprentices include Greg Patrick Gardner (San Jose, CA-based Patrick Cycles) and Mauricio Rebolledo (Rebolledo Cycles in Glen Ellen, CA).

Jeremy Sycip and daughter Leah out for a northern California stroll

It appears the current of handmade bicycle builders is running strong, and the Sycip brothers are just happy to be a part of the scene.

A custom Sycip saddle bag, made of steel and not your typical waxed cotton

For more information, visit www.sycip.com.