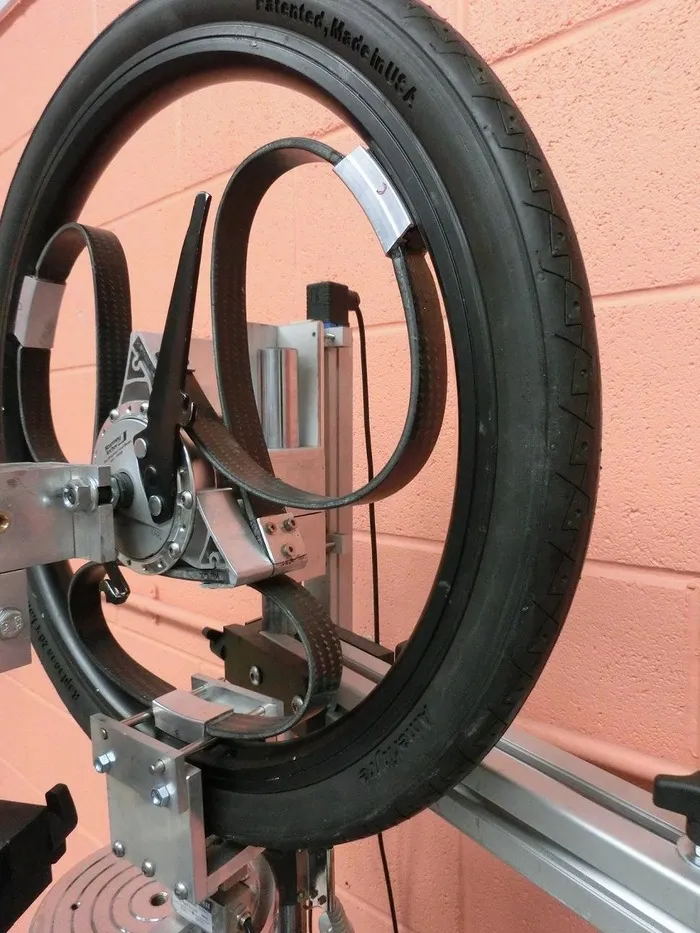

When BikeRadar attended last week's Bespoked Bristol show the last thing we thought we'd come across was someone who had reinvented the wheel. How wrong we were...

Step in Sam Pearce from Loopwheels, who has reinvented the conventional bicycle wheel.

Loopwheels do away with conventional spokes in favour of three carbon fibre springs or limbs. The idea is that this wheel offers integral suspension and in-turn additional comfort to the rider by flexing in a way that a conventional wheel never could.

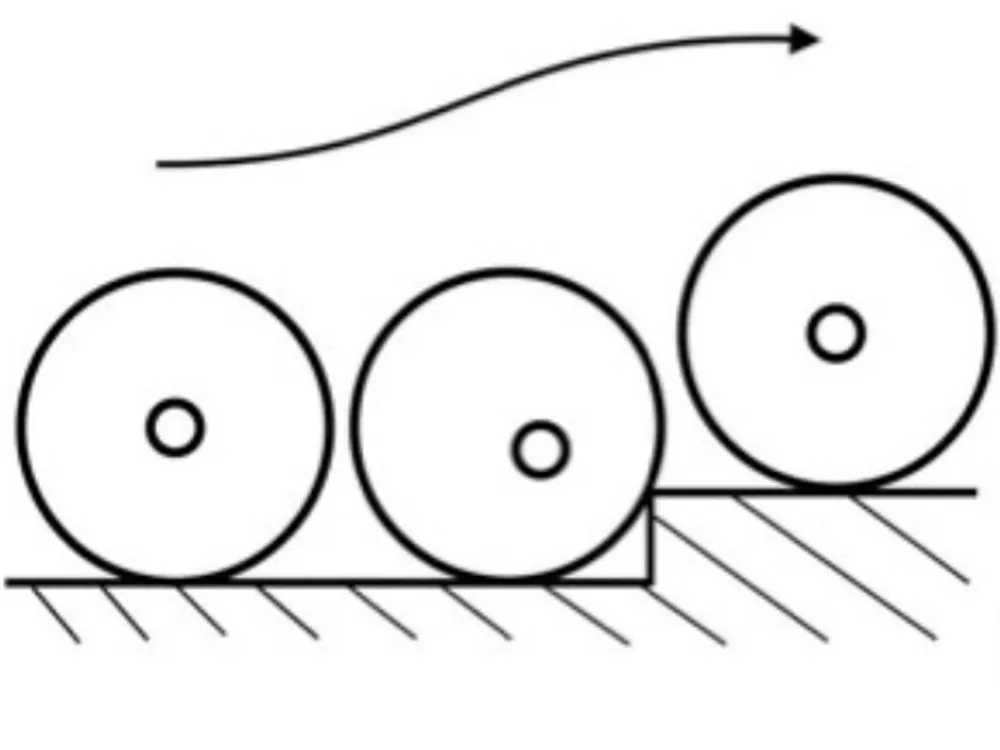

The design allows the wheel to absorb impacts in a unique way. Take for example hitting a kerb head on - the outer rim of the wheel resists flex like any ordinary rim yet the carbon fibre sections will deform in a way that would bring the hub closer to the rim. It's not only a slight bit of give either - the wheel can offer a full 45mm of travel.

This new-found shock absorption is also said to allow riders to fit narrower and more efficient rubber. This is due to the suspension value of large volume tyres becomes less important when twinned with a Loopwheel.

A diagram displaying the unique shock absorption offered by the Loopwheel

Loopwheels are the brainchild of designer and mechanical engineer Sam Pearce, the idea of an integral suspension wheel first entered his head in 2007, yet it wasn't until 2009 that Pearce got the Loopwheels to a prototype stage.

Sam explained his thought process to BikeRadar: “I first had the idea of a wheel with suspension inside it when I was sitting at an airport waiting for a flight. I saw a mother pushing her child in a buggy. The front wheel hit a slight kerb and the child jolted forward because of the impact. It happened several times in the hour I was there and that’s what sparked my idea for better suspension, within the wheel itself.

"I love cycling, so I thought it would be awesome to ride a bike with in-wheel suspension. But it took many, many prototypes, designs and re-designs to get a wheel that really worked well. Then we had to put it through a lot of testing, to check strength, durability and performance, so it’s been over four years in development to get to the product you see today.”

Advancing the design to the near-production stage that it's at now has taken a further four years and a lot of experimentation. Initially Pearce was experimenting with his own composites, with much of his time going into trying to find the optimum spring rate for the composite springs. That's not an easy task as each wheel needs a different spring rate. The rear wheel has to be tuned to manage torque effectively and efficiently under both acceleration and braking whilst still being supple enough to provide the desired suspension effect.

Loopwheels eventually twinned with a UK-based archery firm, whose knowledge of composites proved invaluable for development and now the firm produce each carbon section to Loopwheels' spec.

The design allows for compatibility with nearly all hubs through interchangable connective components between the rim and hub. A loopwheel can also be built to a wide variety of offsets just like a regular spoked wheel, as a result both derailleurs and disc brakes are also compatible. The only real restrictions are that loopwheels don't support rim brakes and they also require adequate clearance between the top of the tyre and the fork crown to make way for their own deformation. This is not usually a problem with a lot of fat-tyred bikes, however, as users can normally scale down the tyres accordingly.

What does the future hold for Loopwheels? We can report that the first generation loopwheel is close to production stage. It will be a 20 inch wheel designed primarily for use on folding bikes. We actually had a brief test ride at Bespoked Bristol on a Dahon folding bike equipped with some pre-production loopwheels, we were immediately impressed at the ride quality but our ride was sadly cut short by a disapproving security guard.

Both Sam Pearce and his devoted wife and business partner Gemma have announced a pledge on the Kickstarter crowdsource funding site. The couple aim to raise £40,000, the money being put towards upfront tooling costs necessary to get Loopwheels on the market.

What is perhaps even more exciting is what is in the pipeline for the future, Sam assured us that both 26 and 29" versions of this design are being worked on. The introduction of this technology in the world of mountain bikes could certainly cause quite a stir.