The team over at Hayes Bicycle Group have been busy this winter working on new products. The biggest buzz surrounds the new Hayes Prime disc brake, but both Manitou and Sun Ringlé also have new bits that offer big performance at relatively low prices.

Prime time

We brought you initial details of the latest stoppers from Hayes Disc Brake back in February, and production models should hit the shops in June. In developing the new brake, Hayes set out a few goals, according to product manager Joel Richardson.

The main focus was on incorporating stroke adjustment and creating the most powerful brake on the market. “We wanted a fully featured brake with tool-free reach and stroke adjustments, but at a reasonable weight – definitely below 400g per wheel,” said Richardson.

Almost all hydraulic bicycle brakes use an open system, which is meant to deal with the heat that builds up during braking. The design also accommodates for pad wear. In the past, Hayes used timing ports drilled in the brake bore to allow for fluid exchange from the reservoir when open and to close the system to build brake pressure when the lever is pulled.

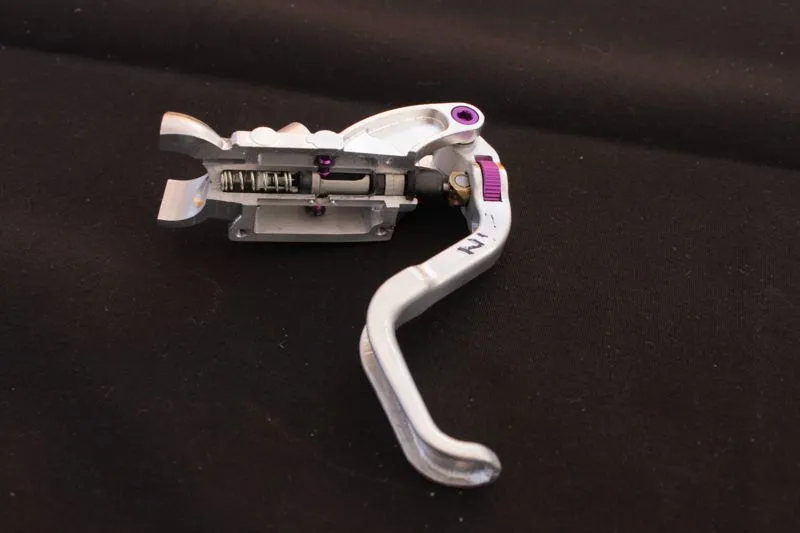

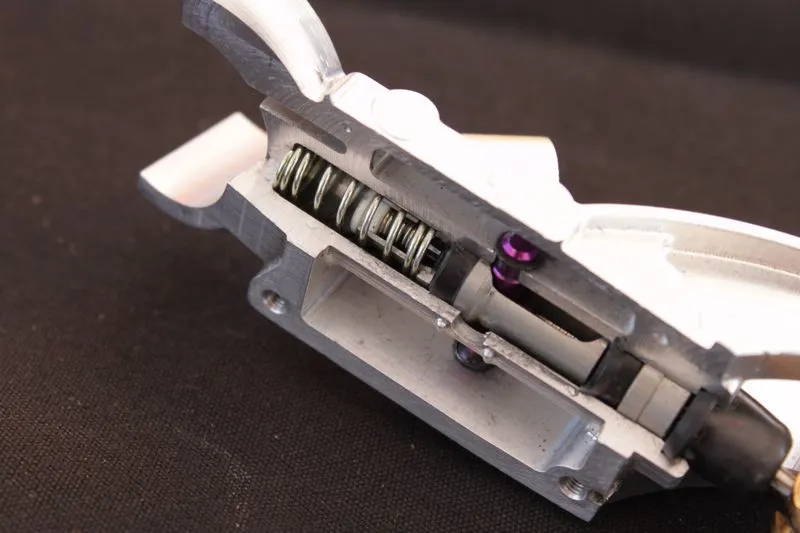

The inner workings of the Prime are displayed in this cutaway

The new system omits the holes in the bore in favour of a hollow piston. Fluid travels through a compensator hole on the reservoir side of the piston. The system is closed when the head of its fluted needle valve, called the 'poppet', enters the O-ring found at the front of the piston. By adjusting the placement of the fluted needle, the brake’s stroke is modified.

“All you’re doing is changing the home position of that poppet, that needle,” said Richardson. “You either travel a lot of dead stroke before sealing or almost no stroke. That’s our stroke adjust and it works really fast and it’s really easy. It’s a compact design. Basically, being last to the game with a stroke adjust system it had to have multiple features and be easy use.”

The system has three benefits, according to Richardson: it provides the brake’s stroke adjustment; it offers increased fluid flow, which betters heat resistance; and it's more durable than a system using a timing port. The Prime uses DOT 5.1 fluid for a better dry boiling point than mineral oil or DOT 4 fluid.

The front dial rotates 180 degrees to give the full range of 'dead stroke' adjustment

On Hayes' Stroker brake, the tool-free reach adjustment is incorporated into the lever’s pivot, which reduces the mechanical advantage of the lever. With the Prime, the reach adjustment is connected to the piston push rod with a pivot that’s housed inside a slide. This allows the pivot to remain in a static position with the lever either extending from it or dropping over it, so that only its position changes, not the mechanical advantage.

The poppet design requires a large piston – at 26mm the pistons in the Prime are 2mm larger than those found in the Stroker Gram or Ace – and this increases the hydraulic ratio, and therefore power, of the brake by roughly 23 percent (depending on which Stroker model you’re comparing it to). Pad surface area is roughly the same as on the Stroker. The bigger pistons require a stiffer calliper and a stronger brake hose to ward off mushiness.

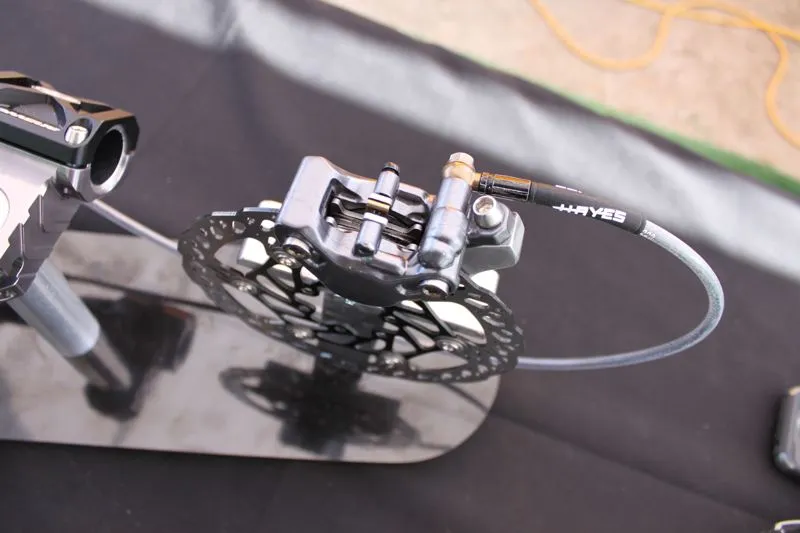

The final piece of the Prime package is a two-piece ‘floating’ rotor. Traditional floating rotors actually float and thus feel loose when rocking a bike back and forth on the showroom floor. The Prime’s rotor pieces are more firmly attached to eliminate this play, but they still allow the braking surface to expand when heated to prevent warping. The new rotor will be available in 160mm, 180mm and 203mm sizes. A one-piece steel rotor will be available in the 140mm size for rear, cross-country applications, which will save 11g over the two-piece 160mm rotor.

The steel braking surface floats on the aluminium carrier via rivet-like fasteners

“The concept behind a two-piece rotor is to maximise the carrier by making it aluminium, reducing the weight,” said Richardson. “You have to use more material in aluminium so that you get a torsionally stiffer rotor versus a one-piece stamped steel rotor. Apples to apples on the 160s, we’re taking about 10g of weight out of the rotor.”

Hayes will offer a choice of pad compound options for the Prime: fully sintered with a copper backing plate, semi metallic with a steel backer or semi-metallic with an aluminium backer. “Apples to apples, that aluminium plate configuration in the Prime is 13g lighter,” said Richardson.

Two Prime packages will be launched for the 2011 model year. The Pro (US$209 per wheel) sports a mix of titanium and aluminium hardware, which brings its weight down to a claimed 385g (front brake with 160mm rotor and all of its hardware). The Expert ($175) subs steel hardware and fasteners, and weighs 415g. Hayes will not offer a carbon lever for the Prime in its first year.

Manitou Circus

While the Dorado Pro is the Manitou fork that gets everyone excited, product manager Richard Travis is particularly proud of their new Circus dirt jump/four-cross fork. The key feature is its price: the Circus costs $399 with steel upper tubes or $449 with an alloy upgrade.

Simple and effective: Manitou say the Circus can compete with both the RockShox Argyle and Fox 831, at almost half the price of the Fox fork

Manitou’s two Circus models feature alloy steerer tubes, dual bottom-out bumpers and an adjustable seven-position ABS damping cartridge with a high-speed compression circuit. The fork uses a firm coil spring to hold the rider higher in the travel and handle hard landings. Travel is internally adjustable from 80mm to 130mm, and the fork comes with four sheets of stickers so you can customise it.

Sun Ringlé PRO

The big news at Sun Ringlé is their licensed use of Stan’s NoTubes.com BST rim technology in their BlackFlag PRO cross-country and Charger PRO all-mountain wheelsets. Both sets use 6061 alloy rims. The BlackFlag set has a 24mm outer width, while the Charger has a wider 28mm rim. The former has a claimed weight of 1,585g and the latter 1,699g, in their 26in configurations. Both wheelsets are also available in 29in versions.

The Sun Ringlé Charger PRO wheelset is one sweet looking, versatile and affordable wheelset

The wheelsets use Flee hubs with high-grade Japanese-manufactured steel cartridge bearings. The front hub is convertible between 9mm quick-release, 15QR and 20mm through-axle, while the rear adapts to 135mm standard, 135mm through-axle and 142x12mm through-axle use, all through use of an interchangeable end cap system. The wheels use 24 Wheelsmith double-butted straight pull spokes, front and rear, and come with Stan’s Yellow Sealing Tape, sealant and valve stems. Each costs $624.