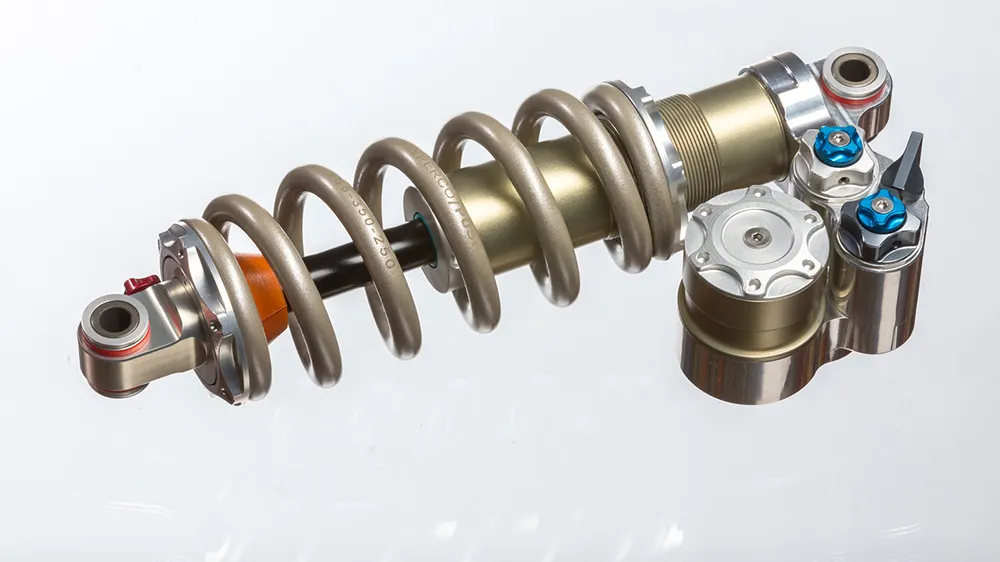

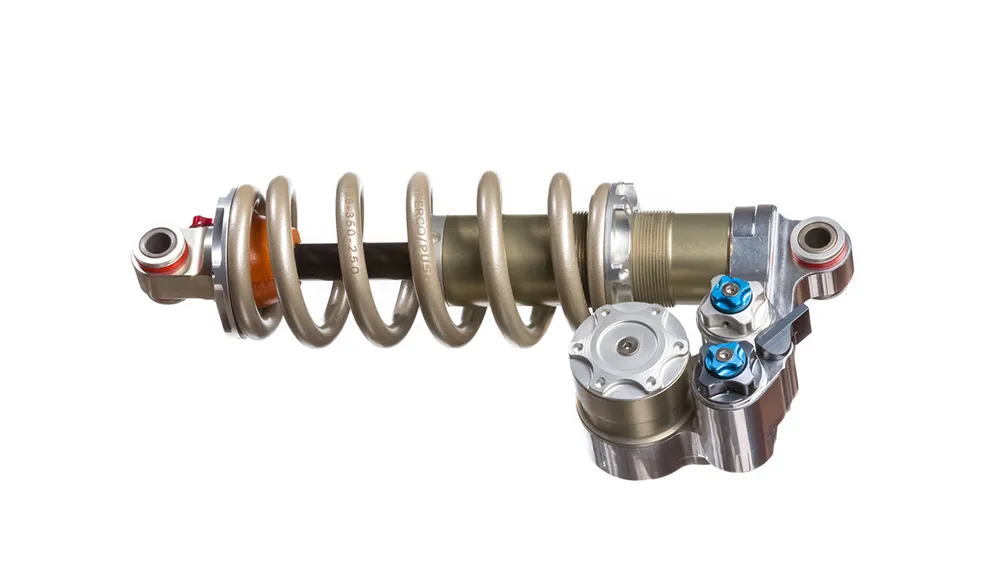

Many BikeRadar readers may be familiar with Push Industries as one of the leading mountain bike suspension tuning outfits. Today, the Loveland, Colorado-based company is broadening its offerings with the launch of its first production shock, the Elevensix. This American-made coil shock comes with a hefty US$1,200 price tag, but seeks to back it up through the use of high-end materials, precision manufacturing, and class-leading customer service.

Not just an off-the-shelf shock

Darren Murphy, the founder and owner of Push Industries, wants to make it very clear that the Elevensix isn’t a production shock in the traditional sense; it’s a bespoke unit manufactured by Push.

Customers will follow a process similar to the one Push uses to tune its customers’ Fox and RockShox forks and shocks. The process starts by having a discussion with a Push suspension tuner and letting them know your make, model, rider weight, riding style, the type of terrain you frequently ride and how you generally want your suspension to perform. Using this data, Push will then build an Elevensix specifically for you. Following that, your shock will arrive with contact information for the tuner who built it, should you have any setup questions.

“We know this isn’t going be to a shock for everyone,” said Murphy.

To that end, Push doesn’t plan to attempt to design the Elevensix to fit every make and model out there, but rather, to target popular models in the 140-160mm category.

Push currently offers the Elevensix shock for the Santa Cruz Nomad and Bronson, the Yeti SB66 and SB6, the Niner WFO 9, the Pivot Mach 6, and the Ibis Mojo HD. Other bikes are currently in the pipeline, including the Banshee Rune, Specialized Enduro 29, Ibis Mojo HD3, Giant Reign, Transition Patrol, Knolly Chilcotin, Norco Range and the Trek Slash.

Elevensix specifics

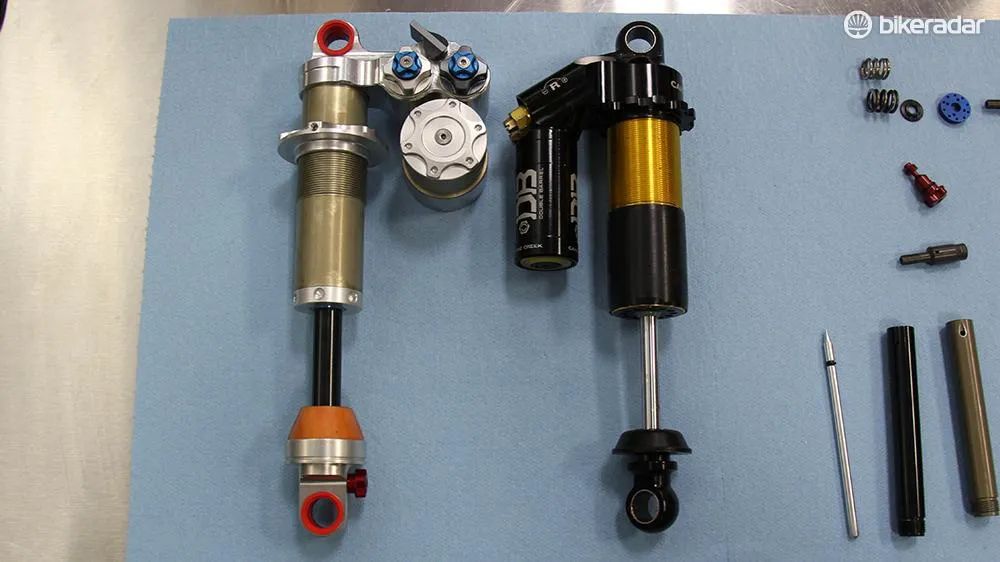

What sets the Elevensix apart from its peers is that it combines custom shock tuning with a limited, but usable adjustment range (think Cane Creek’s Double Barrel meets the Öhlins TTX rear shock).

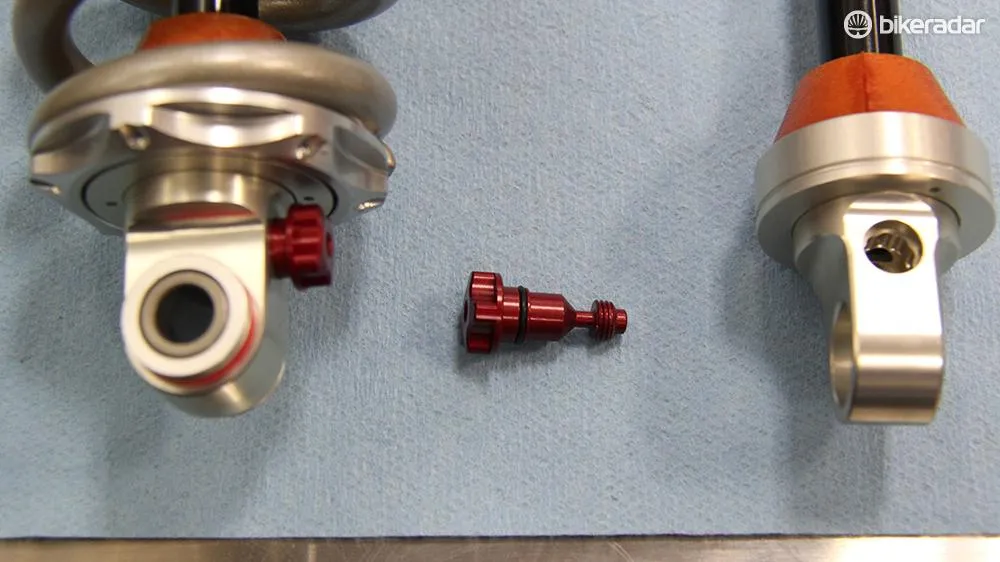

Unlike Cane Creek’s Double Barrel, the Elevnsix is custom-tuned to the bike and rider, so there’s no need for such a broad range of adjustment. All the adjustments are also tool-free, an added plus for the user. Unlike the Öhlins TTX, it offers a wider range of compression damping.

The tool-free adjustment of the Elevensix makes trail-side adjustments much easier

According to Murphy, Push didn’t want to overwhelm users with too many adjustments or too broad of a range. “Even if you get the adjustments somewhat out of whack, it is still going to ride well, as the range of adjustment is limited,” said Murphy.

In terms of external adjustments, the Elevensix offers the rider dual high- and low-speed compression damping as well as low-speed rebound adjustments. The lever on the Elevensix may resemble Cane Creek’s Climb Switch, though its function is completely up to the user.

The patent-pending pair of compression circuits, dubbed “dual-overhead valve,” offer two independently adjustable high- and low-speed compression circuits. The rider can adjust these to suit their needs, such as setting one circuit up with more low-speed compression to slow the shocks movement while climbing, while dialing in the other circuit for optimal downhill performance. The lever allows the rider to toggle between the settings at will.

The Elevensix offer the user two independent compression circuits. Low-speed compression is controlled by the blue knobs, while high-speed compression is controlled by the larger silver and grey knob underneath them. The lever allows the rider to toggle between the two compression circuits

“Some people will set it up so they have a climb and descend mode, other riders might use it for bike park days with one setting set up for fast and flowy trails and the other for rocky trails — you get off the lift, decide which trail you’re going to ride and flip the lever to suit the trail,” explained Murphy.

Since Push plans to build each shock for every rider, they can add or subtract shims for more or less of a platform feel as well.

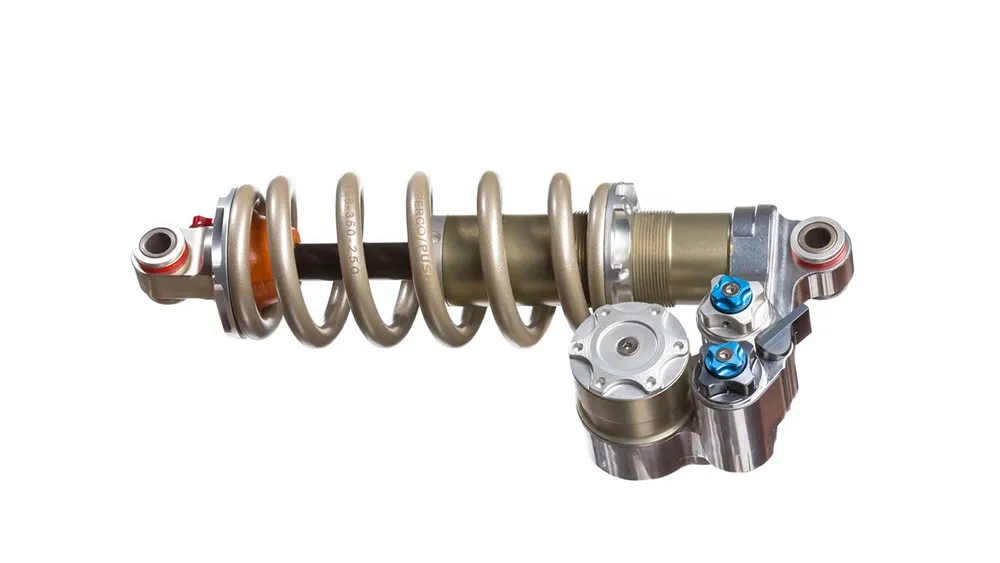

Why use a coil?

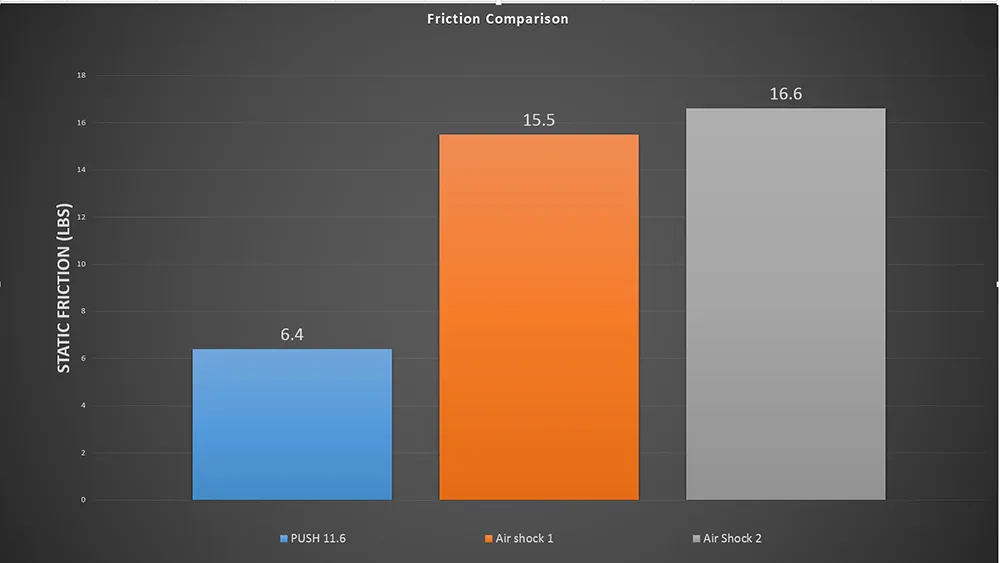

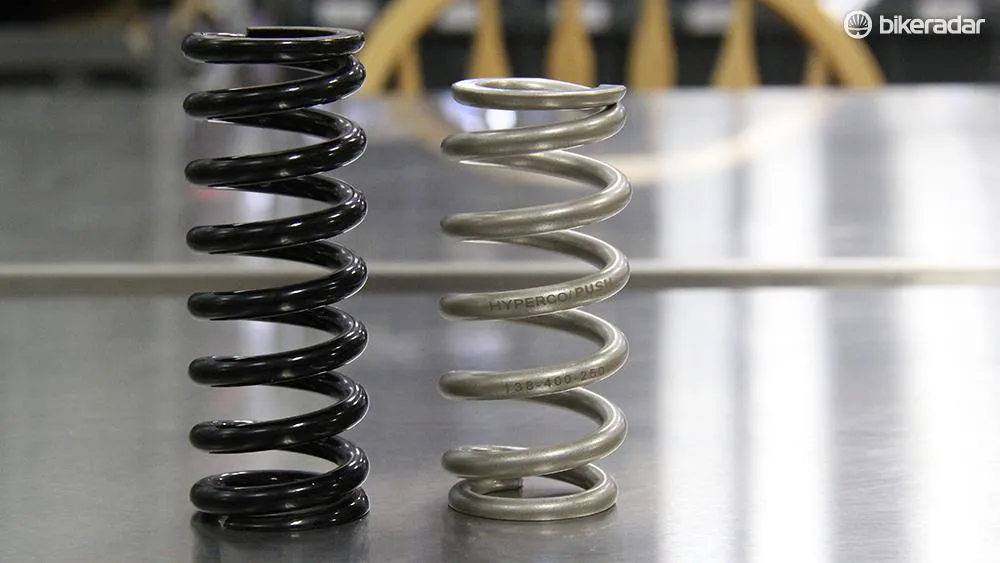

Coil shocks have steadily lost popularity over the last 10 years. Even some World Cup downhill racers have swapped the supple feel of a coil for the weight savings of air shocks such as the RockShox Vivid Air.

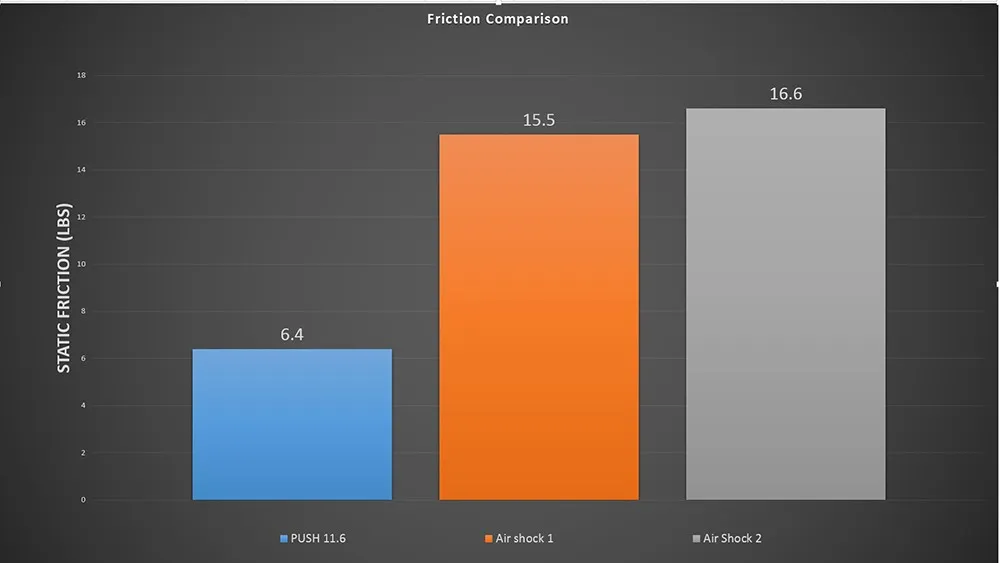

But Push still sees a lot of merit to coil shocks. For one thing, coil shocks have air cans beat when it comes to small bump sensitivity — air shocks have more seals and must overcome more seal friction. Additionally, coil shocks have more oil volume and are more capable of coping with heat build up than lower-volume air shocks. This means they are less likely to experience fade during extended downhill runs.

When it comes to small-bump sensitivity, coil shocks still take the cake

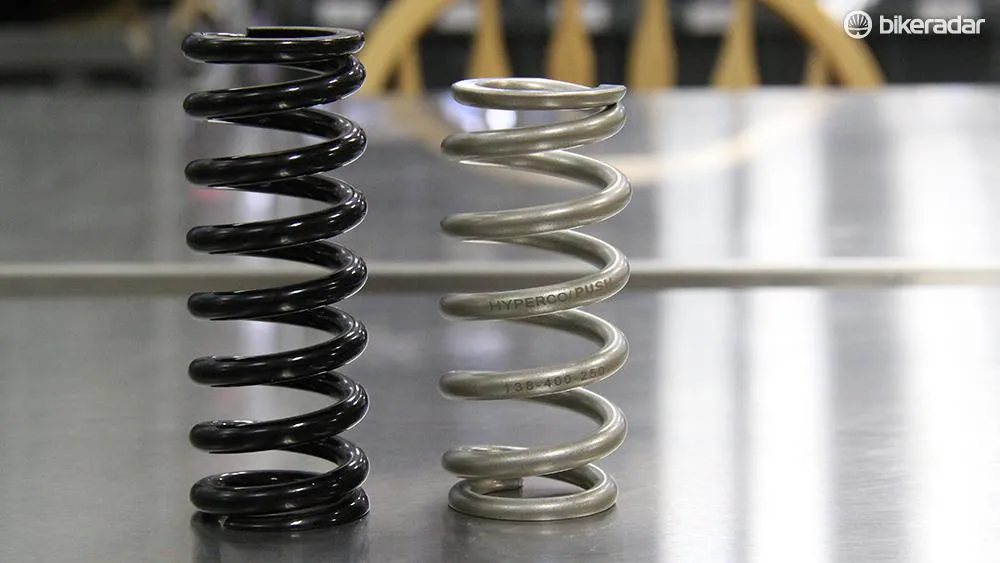

On the flipside, air shocks are lighter and can be more tunable. Push worked with Formula One spring supplier Hyperco to develop springs in 25lb increments (versus the 50lb increments commonly used on other coil shocks) to allow the user to really dial in the shock. The entire shock assembly is also quite light, with a claimed weight of 850g. “We’re a full 100g lighter than our closest competitor,” said Murphy.

Muphy said the company opted not to pursue further weight savings by incorporating a titanium spring because of inconsistencies in the manner in which they are wound.

Details make all the difference

The company began the project on November 6, 2013 (hence the name Elevensix). This seems like a very brief development period from prototyping to production shocks, but many of the technologies included in the Elevensix were honed through more than a decade of manufacturing components to improve other companies’ products.

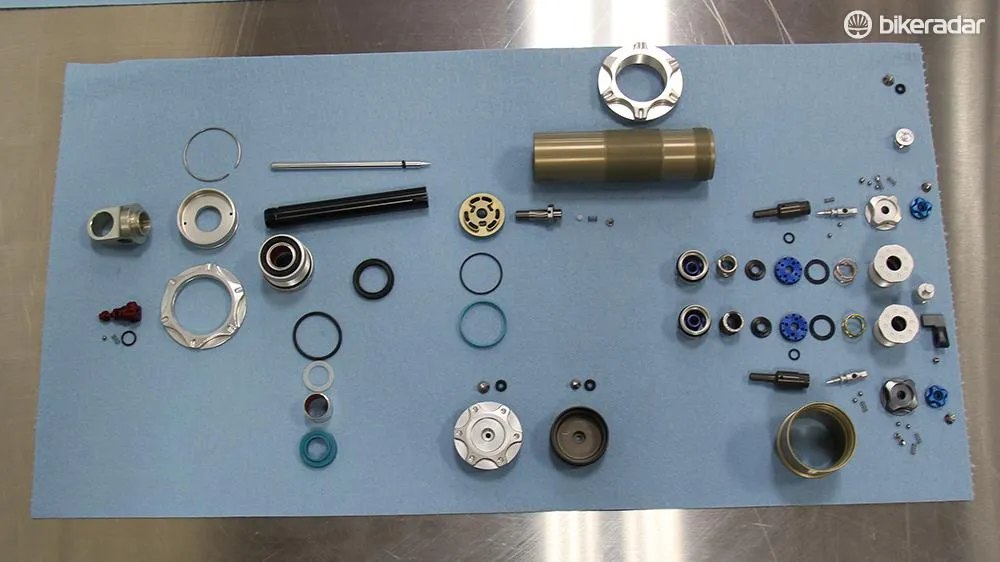

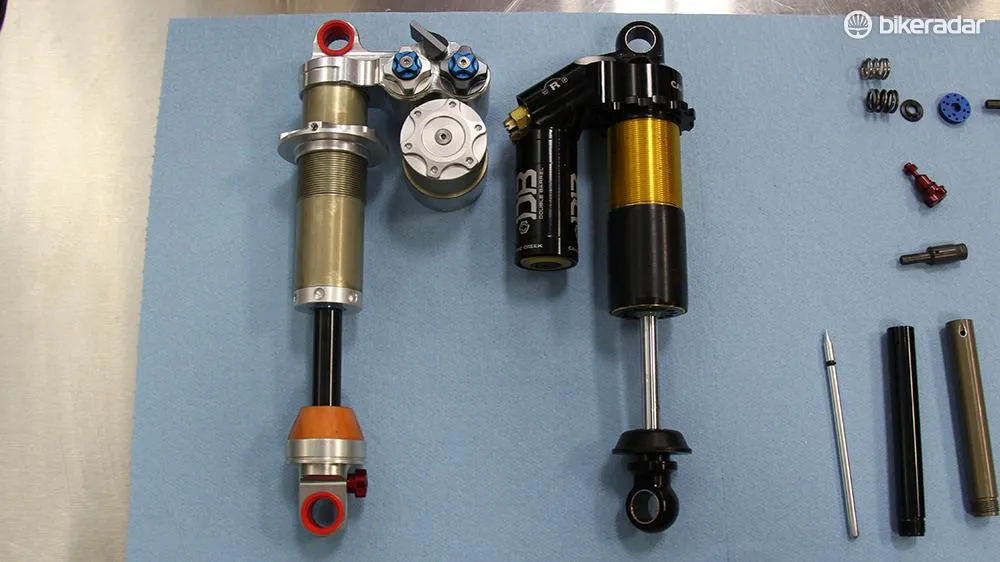

If the devil is in the details, then Push must have sold its soul. Murphy and his team sweated every detail of this shock. All the components are either made at Push or sourced from domestic suppliers to meet the company’s stringent quality standards.

Where other shock manufacturers use 6000 series alloys for shock bodies, Push opted to construct the Elevensix body from 7000 series aluminum, which is twice as costly, but can be machined with thinner walls to reduce weight.

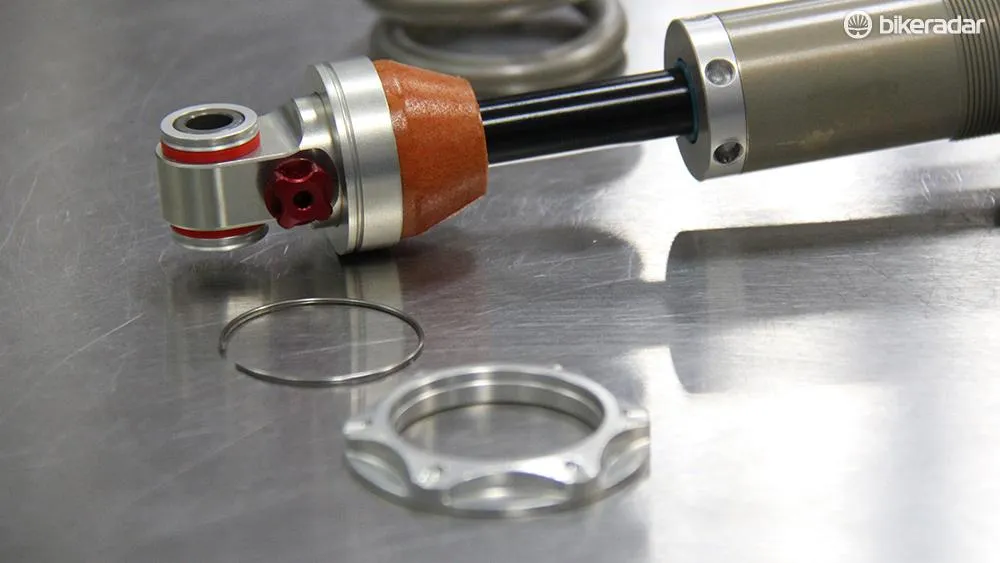

Items not manufactured by Push, such as the rod seal, glide ring and wipers are all top-shelf items from the company’s vendors.

A lot of parts go into the Elevensix, and they are all US-made

“We spared no expense; we wanted the slipperiest materials, the most intricate designs to get us incredibly low friction while maximizing sealability,” said Murphy.

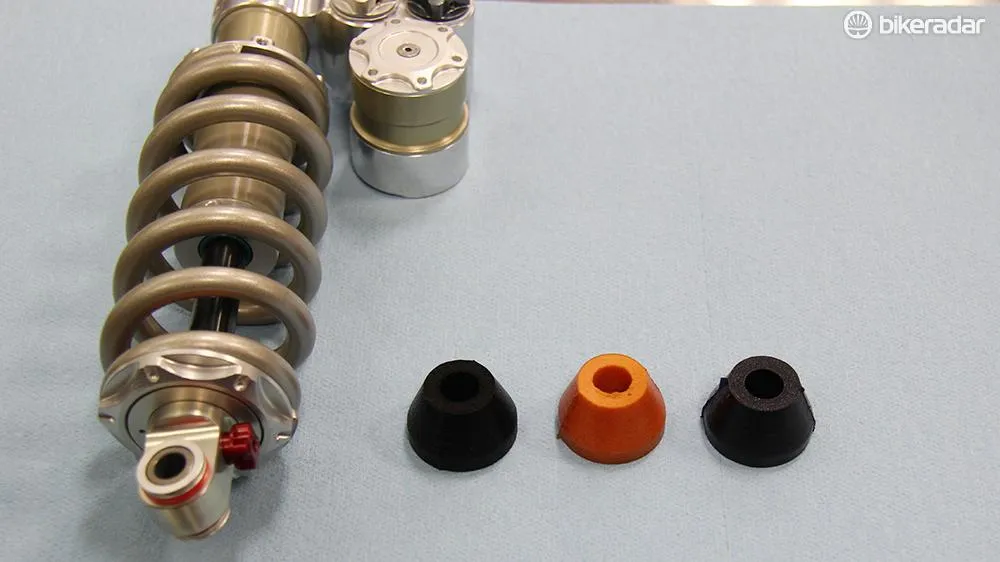

The Hyperco coil spring was designed specifically for this shock. The spring is wider in the middle to improve mud evacuation and ensure the spring doesn’t bind against the shaft.

Hyperco springs are manufactured in Indianapolis, Indiana, for Formula One and other high performance automotive applications. Note how the Hyperco spring widens in the middle

The lower spring retainer is fully captured, with no slot for installation and removal. This ensures proper spring alignment. The lack of a slot in the spring retainer prevents the bumpstop from being forced through the retainer under full compression, which also improved performance under extreme conditions.

The bumpstop is held in place with a small clip

The piggy-back reservoir uses an internal floating piston and sits perpendicular to the shock body, rather than in-line with it. This layout was chosen as it presents a lower overall shock profile, making the Elevensix compatible with more frames.

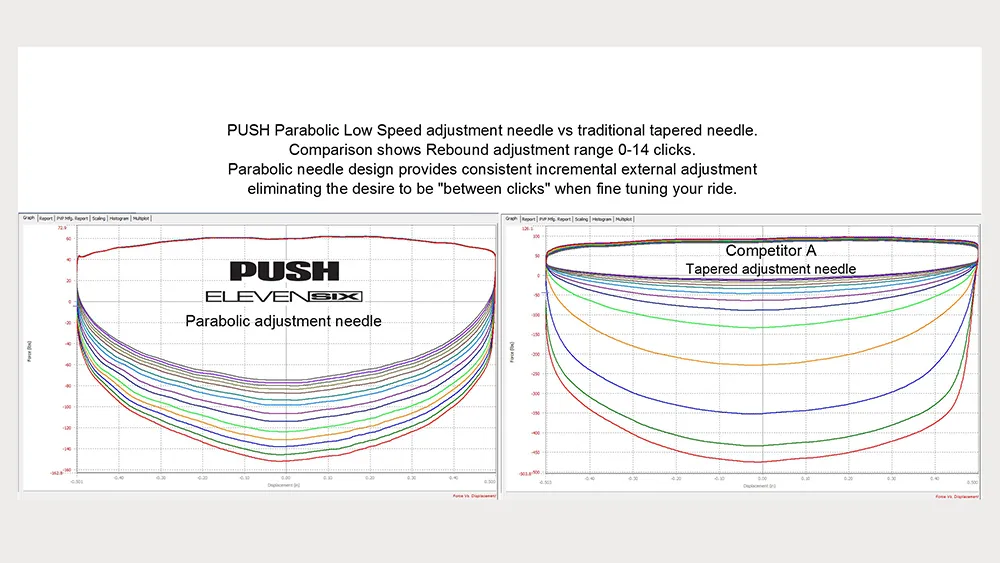

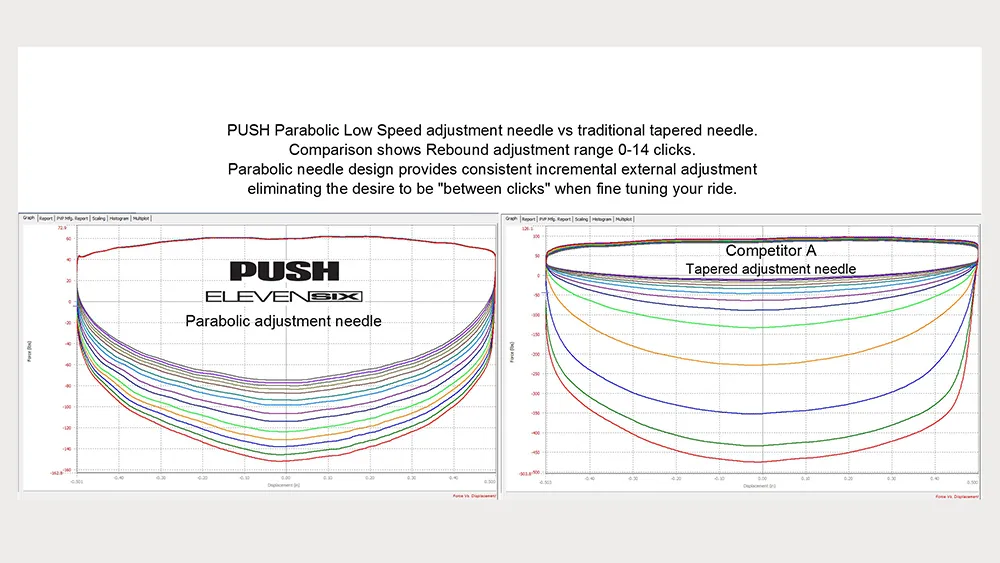

Internally, Push developed a parabolic needle design for the rebound circuit. According to Murphy, the parabolic design offers a more consistent range of adjustment — meaning one click of rebound damping should provide the same increase in damping as the next.

The Push parabolic needle at top provides more consistent rebound adjustments, according to Push

This may seem like much to do about nothing, but if you’ve ever found yourself searching for the Goldilocks sweet spot between too fast and too slow between two clicks of rebound, the shape of the rebound needle may be to blame.

Availability

The Elevensix is currently available directly from Push. Push has also partnered with TF Tuned in the UK, NS Dynamics in Australia and SuspensionWerx in Canada to support and distribute the shock. Visit www.pushindustries.com for more information.