If you’ve ever dreamt of having a mountain bike that’s totally designed around you, then Robot Bike Co’s new R160 could well be the answer.

Rolling on 27.5 wheels and sporting 160mm of rear wheel travel the bike may look relatively conventional, but that’s where the similarity with anything else currently on the market ends. By using a combination of additive manufacturing – that’s 3D printing to you and I – and clever software technology, each and every bike is tailored to the exact dimensions of the rider, allowing a fit that’s fine tuned like never before. It could well point to the future of bike design, certainly at the high end of the market.

- Dutch robots have made a rideable 3D-printed stainless steel bike

- Mojo/Nicolai's GeoMetron plots a future for mountain bike design

- Best enduro bike: buyer's guide and recommendations

Fit as you like

The four people behind Robot Bike Co are a trio of engineers plus time-served mountain bike journalist Ed Haythornthwaite. While the idea about using additive manufacturing and carbon tubing to create a bike had been floating about between them for a long time, it was the restrictions of current high end bikes that was the deciding factor in kicking the project off. As Ed says when speaking about bikes currently on the market: “They’re supposedly no compromise bikes, but they’re compromising on one of the most important elements – fit.”

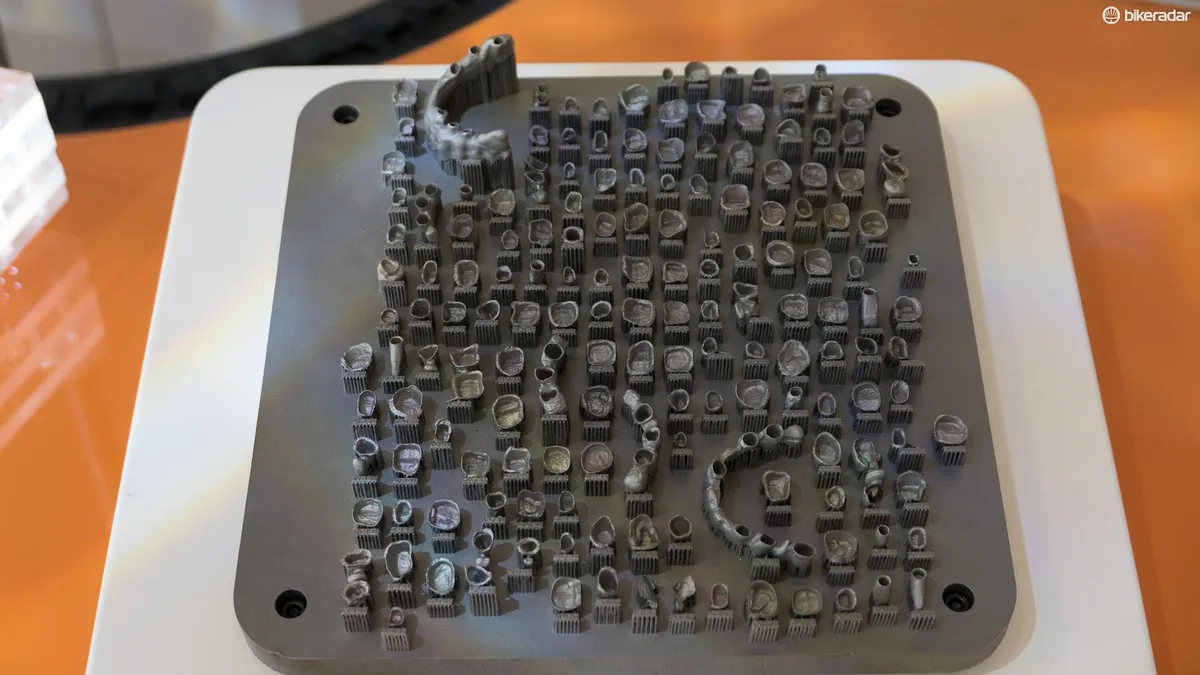

Instead of a fixed mould and set sizes, the R160 is instead made by bonding carbon tubes to 3D printed titanium lugs. As bicycle construction techniques go, lugged tubing is one of the oldest, but taking this technique and throwing the latest technology at it has huge implications. Computer generated designs can be created from titanium powder that's sintered into a solid form by a high power laser in layers just 60 microns thick, allowing an unprecedented design freedom.

The most important element is that they've been freed from the constraints of conventional carbon fibre bicycle manufacturing, where costly moulds limit the sizes on offer and preclude any flexibility beyond the layup of the carbon weave. The additive manufacturing process means that the shape of the lugs and hence the geometry of each R160 can be altered with very little difficulty on a bike-by-bike basis. It's all to ensure that no matter what shape the rider is, they're getting a bike that'll feel and fit exactly how Robot Bike Co intended.

Custom as standard

Most exciting of all, it points towards a future where customisation might be the norm, rather than the exception. Bikes will be sold direct through the Robot Bike Co website, where buyers are asked to input their height, arm breadth and inside leg measurements. Within a few seconds, the software will calculate and generate all the data needed for a 3D printer to create a set of titanium lugs entirely specific to that design, morphing the angles of the lugs to match up perfectly.

Once that process is completed and the metal parts are carefully measured and precision machined, filament wound carbon fibre tubing made to their own specification is then cut and bonded to the lugs. With 11 lugs and eight carbon tubes plus 3 CAD models churning away, a total of 225,720 different possible geometries are available, which rather beats having your pick of small, medium or large.

While the bike fit is custom to the dimensions of each rider, the geometry that’s generated is still based on what Robot Bike Co feel is the ideal, simply scaled to suit the exact dimensions of the rider. The power of the process does mean that should you wish to alter this further, then that’s entirely possible too.

They will charge a small amount extra for this however, not because it’s more costly to create – which is isn’t – but more to cover the time needed to discuss any alterations the buyer wants to ensure that they get a final product that they’re happy with and that works properly for them.

We did note that while the length of the carbon tubing is altered, the diameter and stiffness characteristics of the tubing used is always the same. Ed said that even in the longest possible configuration, it should be more than stiff enough, adding that he feels an overly stiff bike can often be a drawback when it comes to ride and handling in the real world.

Suspension specialist

While everyone at Robot Bike Co is a specialist in their own field, when it came to the suspension platform, they realised they needed to get someone else involved. A quick email to designer Dave Weagle later and he was on board with the project. What he came up with, called the DW6 system, is a rather complicated design that has the goal of being able to isolate pedalling and braking forces as well as keeping tight control over the suspension leverage curve and axle path.

To that end, the heart of the system is two small links that are mounted above and below the BB shell, giving a virtual pivot point slightly in front of the lower shock mount. It's designed to work well with chainrings around 30-32t, though Robot say it's possible to alter the layout of the design to work with larger chainrings, should you wish to run one.

The pivot on the chainstay means that the system should stay active under braking, much like a conventional Horst-link style design, while the rocker-driven shock allows progression to be controlled. Having the shock vertically packaged and mounted to the BB avoids the need for anything to be mounted directly to the down or top tube, keeping things simple and the weight lower.

Talking of weight, at a claimed 7lbs/3.2kg for the frame and shock, it's certainly not the lightest machine in this class out there. For example, a Mondraker Dune Carbon frame tips the scales at around a pound lighter. Even so, a complete bike build should come in at around 29lbs. Robot reckon that they could go around 200g lighter on the frame weight, but that they'd much rather make it able to last a lifetime and accordingly, it's got a lifetime guarantee. Indeed, when testing the tube-to-lug bonding, the five-times safety limit of 6kN of force before failure was exceeded by a large margin - in fact the test machine broke before the bond did at 26kN.

You'd better be sitting down when it comes to the price tag. At £4,395 for the frame, this is not a cheap bike, but the level of technology involved means it was never going to be. Robot don't plan to do complete bikes - they feel anyone wanting something so personalised is unlikely to want a set menu approach to finishing kit - but they can build you something up if you desire.

In a day and age when it's perfectly possible to spend similarly serious money on a mountain bike prised from a mould in the Far East, having a totally custom bike made especially for you is a rather special thing. Compared to conventional custom bikes, which can often take months from design to delivery, their unique process means they estimate a turnaround time of just four weeks, depending on demand.

On the shoulders of engineering giants

Obviously the technology that powers the manufacture of this bike is out of the reach of most major brands, never mind a tiny start-up. The bike is actually the product of collaboration between Robot Bike Co and engineering firms Renishaw, HiETA and Altair, all of whom brought a different skillset to bear on the project.

Fancy Ti teeth? Renishaw can do that...

Renishaw is a giant company best known for high precision measuring probes, but one that is also at the forefront of additive layer manufacturing. Their technology is hugely widespread in military, medical and industrial applications, but the sensitive nature of these projects and the commercial partnerships involved mean they don’t often get to show off just what they can do with this rapidly developing technology.

They're keen to do this because, at present, the process is still relatively unknown and it's this that prevents real progress from being made. At present, many designers are unsure of how to apply the technology when they've been used to more conventional machining or manufacturing processes for so many years.

Helping more people understand the process and realise the alternative ways they can create things will drive greater adoption, which will then mean that the currently sky-high costs for materials and machines will start to drop as they are produced in bulk.

So many Ti teeth...

If the name Renishaw seems familiar, then it's because they've been involved with some bike based projects before, namely Empire Bike's MX-6 R, which was made entirely from 3D printed titanium. It'll come as no surprise that this project was simply to expensive to be a viable commercial product, something the R160 definitely is.

Altair is an engineering design company that specialises in software and services. A particularly impressive and important software package allowed the basic design of elements of the bicycle to be highly refined by inputting the forces they'll be subjected to and then calculating exactly where and how much material will be needed to provide suitable strength and stiffness.

For example, the chainstay yoke went from being a fairly conventional looking item with a cross brace to an amazingly delicate and almost organic form. It's a prime example that shows that this soft of software combined with the additive manufacturing process can free designers up to create components in ways that simply haven't been possible before.

HiETA are also additive manufacturing specialists based nearby to Altair and when Robot Bike Co approached them for advice on setting up a business, they quickly became involved, with two of the Robot crew joining the company. For HiETA, it's a chance to show the power of additive layer manufacturing and to demonstrate that this is a technology that's ready to be commercially exploited right now, rather than a niche and specialist process only used in applications where cost isn't an issue.

Are Robots the future?

There's no doubt that the R160 is an extremely niche proposition. It's a premium product at a premium price, but it does offer something never seen before; namely the completely new approach to fit and sizing. It's obvious that the technologies used to create this bike are only going to more advanced, less expensive better understood and therefore exploited in even newer ways.

Will this replace the way entry-level bikes are made? Almost certainly not, but at the high end, it could point to a future where the idea of buying off the shelf is an unthinkable as this sort of mass customisation is now.

We can't wait to get out on the bike and see how it rides in the real world, something we hope to be able to do soon. Regardless of performance, the R160 could be one of the most influential machines ever made, simply because it points to a future where what was previously unachievable becomes commonplace

If this has intrigued you enough, then the robotbike.co website is now up and running and ready to take orders. Do let us know what you think in the comments below...