Imagine never having to clean your bike ever again, even after the muddiest or wettest ride. That may sound like a pipedream but a new laser etching technology developed by researchers at the University of Rochester's Institute of Optics brings that fantasy a little closer to reality.

The idea of a self-cleaning surface is nothing new and spray-on treatments such as Ultra-Ever Dry and NeverWet are already on the market. While they work quite well at repelling mud, dirt, oil, and water, they're also messy to apply, prone to wear, and produce a hazy, matte finish – all of which makes both products only marginally appealing to the cycling world.

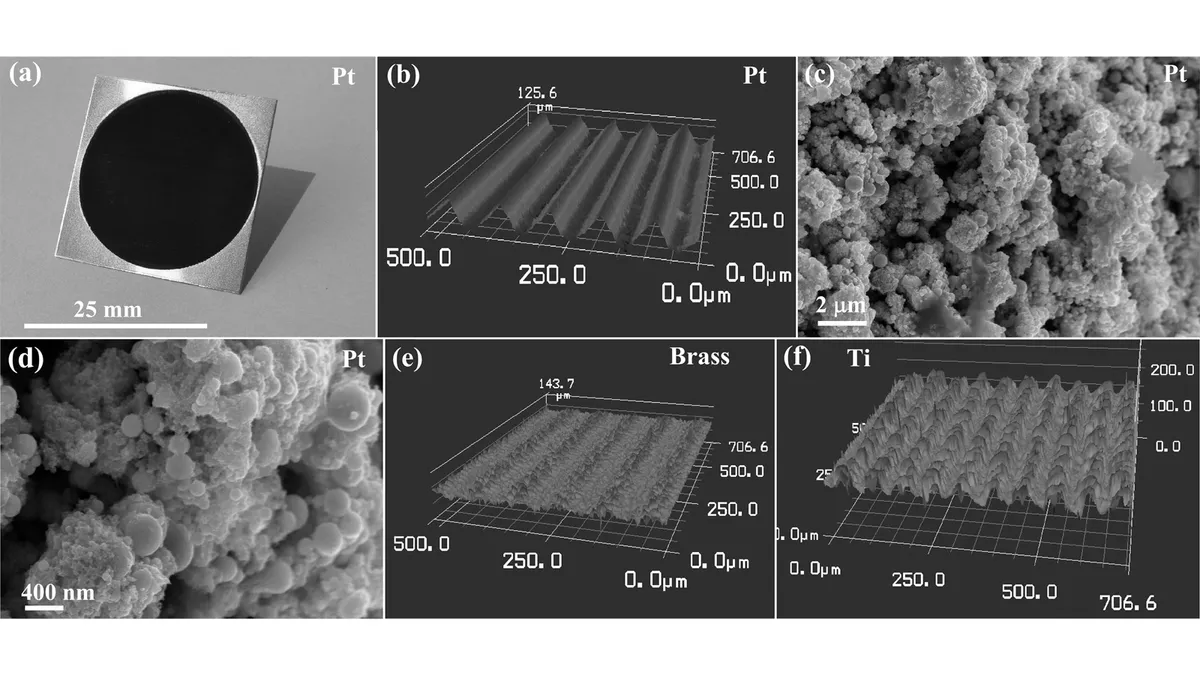

This new technology, however, instead uses a novel, ultra-fine laser etching technique to produce a microscale texture directly on the material itself while still retaining a glossy outward appearance.

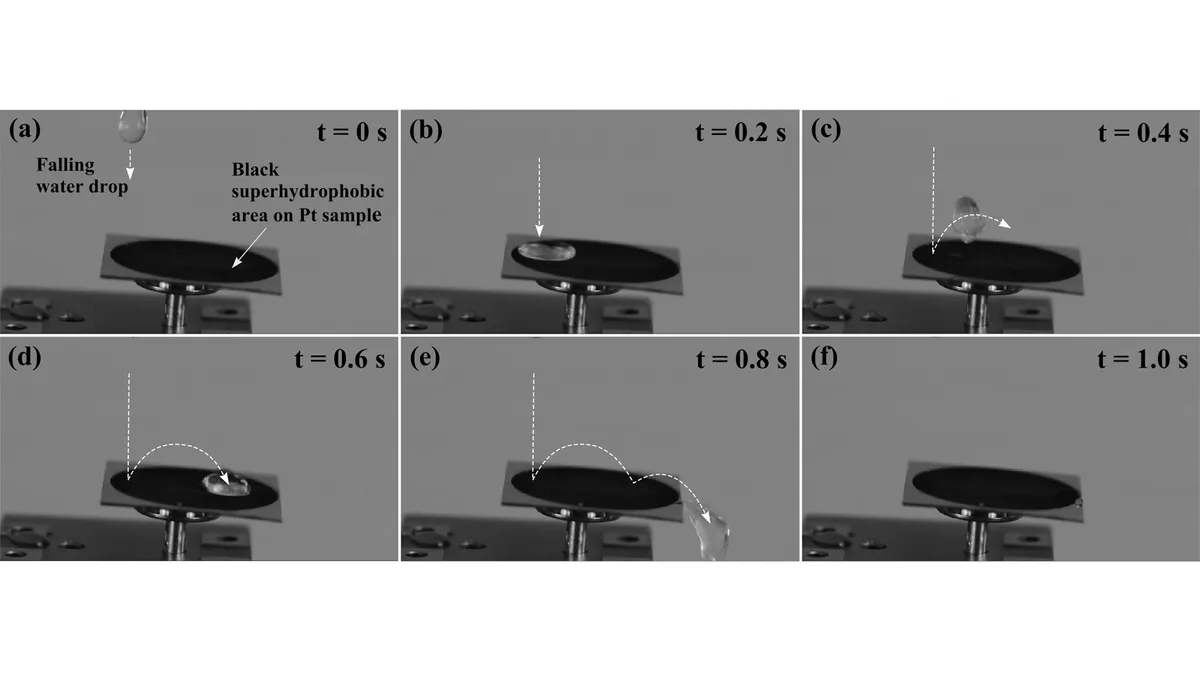

Dirt and other contaminants would not have sufficient surface area to stick to and thanks to the ultra-hydrophobic properties, water droplets don't just slide off the surface – they actually bounce off. Just like the leaf of the lotus plant, whose unique surface is artificially replicated here, those water droplets also tend to carry with them whatever particles do manage to stick, effectively creating a truly self-cleaning surface.

Just imagine how clean your bicycle would stay if water and mud bounced off the surface like this

Video: Just imagine how clean your bicycle would stay if water and mud bounced off the surface

While a PhD in physics is certainly helpful in developing such technology, it doesn't take much to see how cyclists could benefit from treated frames, components, and wheels. Mountain bikes would stay clean after even the sloppiest rides, 'cross racers would have almost no reason to pit, and your road bike would look like it was freshly prepped by a Tour de France team mechanic every time you rolled out the door. Meanwhile, winter fat bike riders would never have to worry about ice buildup.

The concept is not without its limitations, of course.

The technology currently only works on metallic materials, which are not only rendered pitch black in the process but also end up with a matte finish. It's also unclear how such a finely etched surface pattern would hold up to abrasion or if the process can be practically applied to larger objects.

Read the complete paper to learn more, and in the meantime, head over to our forum to discuss this technology's potential benefits.

While you don't need a ph.d. in physics to see the benefits of a self-cleaning material, you might need one to develop the technology

Video: While you don't need a PhD in Physics to see the benefits of a self-cleaning material, you might need one to develop the technology