Specialized have unveiled a new version of their S-Works road shoes at their 2013 product launch in Snowbird, Utah.

This is no evolution but a ground up redesign, a development which began over two years ago around the time the previous version hit the market. The team working on it was headed up Specialized's design head of footwear Rob Cook, with input from Dr Andy Pruit and Rob Pickles at BCSM (Boulder centre of sports medicine).

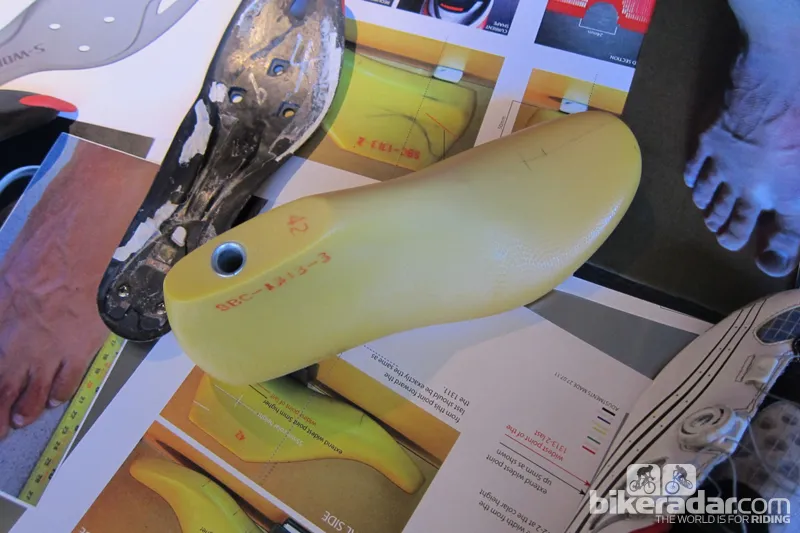

Some 37 prototypes have been made to produce the finished shoe, from a usable 100g shoe to a version with a carbon bathtub construction which because of a totally inflexible sole meant you could only squeeze your foot in with a large amount of force. Such extreme features divided opinion in the guinea pig testers, with the finished shoe a compromise between weight, stiffness and fit which has already been used by pros to great success.

One of their many prototypes

Tom Boonen received a pair of pre-production samples prior to the Tour of Qatar. Specialized wanted the Omega Pharma - Quickstep star to give them a try prior to the race and provide feedback on any changes he'd like to see, but he actually ended up racing in them -- to overall victory, no less -- and has continued to do so since, having the best Spring Classic season of his career.

Fit

The new shoe required the design of a whole new last (the form on which the shoes are manufactured), shaped by feedback and data acquired from both pro and amateur riders. It has a mapped 3D heel form with a plug-fit feel which holds your heel in the shoe better, all but eliminating the chance that your foot could lift away from the shoe under hard pedalling efforts.

This all-new shape and construction make for a heel section that’s significantly stiffer torsionally than the previous shoe. The shape has also evolved around the instep and arch, a more ergonomic fit which, when combined with the correct foot bed, one that offers better support, too.

Up front the toe-box has been reduced in volume for a closer fit. The shoe is also available in a women’s version that has all the same characteristics with the small but significant change being that the shoe collar is reshaped and lowered; anatomical data shows that women’s ankles are closer and shorter to the heel than men’s.

Material

After months of research to find the ideal material, Specialized found that one wouldn't be enough. They'd need different materials in different parts of the shoe as some areas needed more stretch than others.

Up front the fit has to be adaptive, so the mix is a lightweight air mesh and synthetic leather with plenty of stretch. The heel material is selected for lightweight and hi-tensile strength with minimal stretch for a highly supportive fit, anchoring the heel in place and extending all the way to the inner arch for a stable platform.

The carbon sole is also new, with a ‘power line’ design that concentrates stiffness along a rider’s big toe-ball-heel centerline

Construction

Each section of the shoe is laser cut, with the pattern cutting layout set to make sure the materials stretch characteristics are optimised. These pieces are thermo-bonded together (hot-plate welded) which creates a sock-like one piece upper.

Shape

The tongue section is now radically off-set with the dual Boa closures set further into the shoe's side, a feature Specialized say makes the shoe easier to adjust from the saddle.

The outsole is where most of the new design work is found. BCSM did a 99 point pressure test, which gave a map of pressure points as well as the size and amount of those pressures. It allowed them to design a sole that’s stiffer and thicker where it needs to be and minimal and lightweight where it doesn’t.

The carbon sandwich structure is just 4.5mm thick for a low stack height (the shoes ship complete with shorter bolts for this reason). The medial side of the sole is ‘L’ shaped to create a supportive form around the inner foot.

Testing

BCSM took the prototype of the final shoe and undertook tests on the all-new chassis. With the shoe optimised with pro foot beds and inserts dedicated to that rider, they found they were 28 seconds faster over a 10km time trial (on a roller set-up in lab conditions) against the previous version - a huge gain.

BCSM also tested the shoes straight out of the box with no optimisation and found over the same course that the rider had a 6.5 watt improvement, with less knee deviation. We can only take them at their word as we’ve yet to try the new shoes. We'll be testing them out over the coming days so we'll report back soon on our initial impression.

The new shoes are designed to work with a new line of Body Geometry insoles, which are made with new denser, foam said to last three times longer than the previous edition