We’d long heard rumblings of a new 11-speed mountain bike group coming from SRAM. We expected it to be an updated XX with a wider range that more closely replicated a conventional triple. Instead, SRAM have developed a progressive, dedicated, single-ring 11-speed group called XX1. The company hope it will change mainstream thinking in terms of mountain bike drivetrains.

We happened to score an in-depth look at the prototype during our recent visit to SRAM’s European headquarters, where we got a lengthy sit-down with drivetrain product manager Chris Hilton. We also got to pedal the bits around a little, too.

What is XX1?

SRAM aren’t pitching XX1 as having 11 speeds. Instead, they’re describing it as a 1x drivetrain that just happens to have 11 cogs out back. The heart of the XX1 concept is its ultra-wide, 10-42T cassette, which provides a generous 420 percent range. That still falls short of the XX’s rough 470 percent but it’s a big improvement over current 1x10 drivetrains that many riders already run. In essence, the XX1 cassette adds a gear on either end of a current XX cassette while retaining reasonable jumps in between.

“We’re not trying to start an 11-speed war,” Hilton says. “A 1x11 war? Fine, but a 2x11 war isn’t beneficial to anybody.”

SRAM also don’t intend for the XX1 to replace current 2x10 groups. Instead, they’re aiming it at trail and enduro riders who are often already strong enough to power a single-ring drivetrain. The target group often also place a major emphasis on chain retention and impact protection with dedicated guides and bashguards.

Nonetheless, SRAM are fully expecting a smaller faction of forward-thinking cross-country riders to jump on board as well. As well as being simpler and more secure than the XX, the XX1 is also lighter. Target production groups are 200-300g relative to the ultra-light XX.

“Almost all of that is from omission, not from anything getting lighter,” Hilton tells BikeRadar. So there shouldn’t be any drop in overall durability, either.

Final pricing is still to be determined but SRAM plan to launch the XX1 later this summer.

Unable to load media

Video: SRAM's prototype XX1 drivetrain

New cassette, new freehub body

The XX1 cassette construction is very similar to that of XX, mostly machined from a single block of steel to form a hollow, domed structure. That dome is then capped with an aluminum innermost cog – in this case, one that’s much more dished than the one on XX. This also transfers all the drive torque to the splined freehub body. Instead of having the smallest cog as a separate bit, XX1’s 10-tooth cog is now integrated into the rest of the steel structure.

Squeezing on a 10-tooth cog required some doing, as it’s too small in diameter to fit on a conventional freehub body. So, SRAM created a new ‘XD’ driver body that’s essentially a slight modification of what’s currently in use. The end where a conventional lockring would normally thread into is lopped off. And almost all the splines on the outside of the body are shaved smooth to leave a mostly bare cylinder.

The new 'XD' freehub body is essentially just a modification on a standard SRAM/Shimano 9/10-speed driver. The threaded end is cut off as are most of the splines, then new threads are added at the base of the body to secure the locking tube. Otherwise, the body is unchanged so it rides on the same bearings, bearing locations, and axles

A Delrin-lined aluminum locking ‘tube’ replaces the conventional lockring. The ‘tube’ snaps into the inside of the 10-tooth cog but is otherwise free to rotate. Threads at the inner edge then match up to new threads added just outboard of the remaining freehub body splines. The Delrin lining is sized to provide a light press-fit on the freehub cylinder. When it’s all secured, the locking tube keeps everything firmly concentric on the freehub body, with no chance of cogs digging into its surface. It’s not very different to how a non-driveside SRAM GXP crank arm attaches to a bottom bracket spindle.

Because all the freehub body modifications are restricted to the exterior, an XD body can be adapted to current hub designs with no changes to things like axles, bearings and spoke flange spacings.

The XX1 cassette fits onto a modified XD cassette body

For now, wheels will be available from SRAM and DT Swiss only for sure although recent imagery released by SRAM suggests Mavic is on board as well. Hub spacing will remain unchanged at 135mm or 142mm. Licenses to other makes are under discussion, but given the prevalence of DT Swiss drivers in other companies’ wheels that should open things up to the likes of Specialized, Reynolds, Enve Composites, and others right away.

XX1’s 11-speed cog spacing will be unique to the group, however, and isn’t shared with 11-speed offerings from Shimano (more on that soon) or Campagnolo. Of course, there’s a dedicated 11-speed chain as well, with a slightly narrower external width. Inner plate spacing and roller width are unchanged from SRAM’s 10-speed chains, though, so wear supposedly isn’t adversely affected.

Weight weenies shouldn't be concerned about the XX1 cassette's huge size, either. According to Hilton, "at present, the 10-42T 11-speed cassette is lighter than an XTR 11-36T 10-speed."

Straight P derailleurs

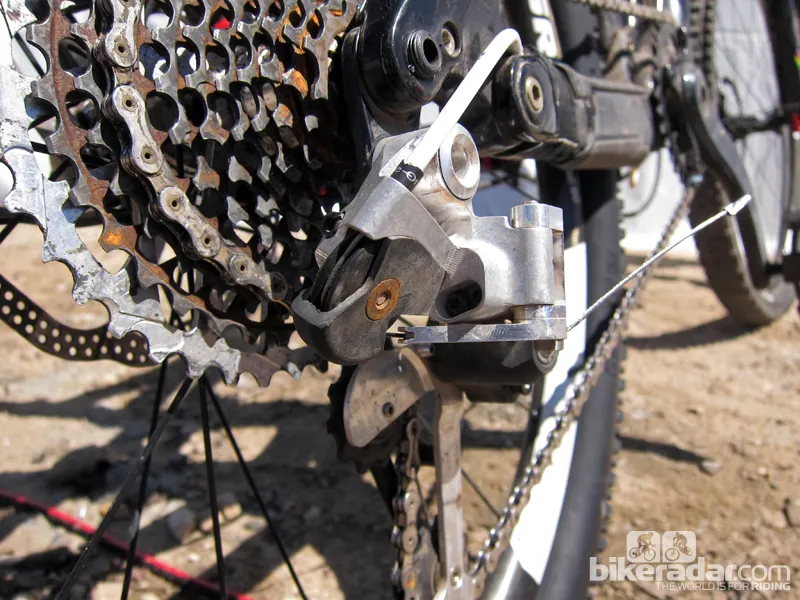

The XX1’s rear derailleur will signal a radical departure from current designs. With a conventional slant parallelogram the derailleur body simultaneously moves the cage in and out as well as up and down. But the XX1 will use a so-called “straight P” layout where the body only moves along the horizontal plane. It’s an idea Hilton admits has been floating around within SRAM for the past eight years but is only now seeing the light of day with the rise of 1x drivetrains.

Hilton acknowledges that a straight parallelogram is counterintuitive. One would assume that the derailleur body should follow the contours of the cassette, but the XX1 cassette’s extreme gear range and tighter cog spacing necessitated a change in thinking.

“Originally, the first prototype of this was built for a downhill bike,” Hilton says. “We built it because when bikes hit bumps, the derailleur absorbs the shock of that chain. So you hit a bump today and you’ve got your chain mass and your derailleur mass. It can actually activate the parallelogram and cause ghost shifting. If you add a clutch to that and you’ve really significantly stopped that force, you’ve actually added to the potential for ghost shifting. We’ve compensated for that [in current Type 2 rear derailleurs] by not decreasing our spring tension in derailleurs.”

Because XX1 doesn’t rely on a slant parallelogram to control chain gap, the upper pulley is now hugely offset from the lower derailleur body knuckle. As the chain shifts across the range, more or less chain is wrapped around the cassette, pulling the cage fore and aft and the upper pulley up and down.

XX1 will only be offered with a single 10-42T cassette ratio, so that upper pulley pivot offset could be precisely calculated to keep chain gap consistent across the entire range.

“The chain gap is exactly the same in every single cog no matter what cog you’re in, even if you were to change the cassette, because it’s driven by the amount of free chain length,” explains Hilton.

The XX1’s “straight P” design also means it will only work with a single-ring crank. Likewise, suspension designs with lots of chain stay growth could be problematic.

Naturally, the XX1 will feature SRAM's new Type 2 roller bearing clutch to squelch excess pulley cage movement on bumpy terrain. Other details include an integrated cable pulley at the rear of the derailleur, just like on Avid’s long-defunct Rollamajig, to decrease cable friction. We expect production units to be built with cold-forged parallelogram plates and a carbon-fiber pulley cage.

The 1x11 concept doesn’t require a huge re-engineering of shifters. Therefore, XX1 models will essentially be the same as current trigger and Grip Shift offerings, albeit with different badging, an extra click and specific internal spacing.

No chain guide required?

XX1 was conceived as a single-ring drivetrain, allowing engineers to rethink the chainrings as well. Conventional 2x or 3x chainrings are designed with elaborately shaped teeth to improve shift performance but this also affects ability to retain the chain on bumpy terrain.

“As we make chainrings shift faster and smoother, we’re taking material away, making them more expensive, limiting their lifespan and potentially affecting chain retention capability,” says Hilton. “There's no question that making a chain shift makes a chain fall off.”

As a result, XX1’s chainring teeth are unusually tall and quite squared-off, similar to those found on dedicated singlespeed rings. However, they’re also built with alternating tooth thicknesses that are syncronized with the gaps in the chain – slightly narrower to fit between inner chain plates, and wider to take advantage of the extra space between outer chain plates.

Combined with XX1’s improved chainline, Hilton claims this improves chain retention to the point that you won’t need any sort of guide in most applications, while also slowing down wear and reducing drivetrain noise. Hilton admits that aggressive trail and enduro riders might still choose to run some sort of minimal upper guide, if only for peace of mind.

“I like to say that chain retention is sort of like birth control – there are various levels of safety,” he quipped. “You could choose to use a full-on X0 DH guide with bash protection and a lower roller in addition to this whole system but that would be like abstinence."

The XX1 drivetrain fits in well with the 'new school' of trail bike kit, which includes wide bars and short stems

The synchronized design of the chainring teeth will limit the XX1’s chainring choices to even numbers. But the overall range is admirably broad – all the way from 28-38T. That variation will require a dedicated bolt circle diameter, but the spider will be shaped so that users won’t have to remove the cranks to swap rings. The production crank will feature hollow carbon-fiber arms and be offered in both narrow and wide stance widths (we’re guessing 156mm and 166mm, as for current XX cranks).

1x11 drivetrains: the bonuses

Why go to all this trouble just to eliminate a chainring, though? Don’t current 2x10 systems already work well enough? That all depends on who you ask.

It’s true that modern two-ring drivetrains work well. But they still can’t match the security of single-ring setups, which are increasingly finding favor in the mainstream marketplace, especially with more aggressive riders. If you need proof of that, just note the explosion of two-ring chainguide models in recent years.

Moreover, single-ring drivetrains are simpler and lighter, as well as less confusing to newer riders. Hilton doesn’t refute the idea of eventually bringing the 1x11 concept to much lower price points and XX1’s gearing range sounds generous enough to be useful for a wide swath of riders.

“As long as you choose your range properly, this type of system is applicable to a majority of people,” Hilton says. “It’s not intended to replace 2x10. Some people need a bigger range, and that’s fine – we still have 2x10. But if you’re Ross Schnell or various other people, this is a radically improved 1x10.”

Hilton also points to the difficulties an OEM company can face in terms of getting front derailleurs to play nicely with the huge range of rear suspension designs.

“Front derailleurs are limiting because there are so many choices,” Hilton says. “It’s limiting because of where you can move the wheel to, where the suspension pivots are placed, where the cable routing comes from – all those things are limitations to a drivetrain. Front derailleurs are one of the most expensive engineering and tooling costs on a bicycle, yet it’s the first place manufacturers go to cut money.”

So why not use a 2x11 setup? Combined with that 10-42T cassette, such a drivetrain could easily replicate the full range of a traditional triple but with the advantages of a double.

“2x11 is certainly feasible – it’s not impossible,” Hilton says, though he also adds that the cassette’s added width presents problems with chainline if more than one chainring is used. “11-speed is a by-product of wanting to make a wider-range cassette without funky steps in there. We want to sell it as a 1x drivetrain solution that just happens to have 11 gears. The eleventh gear becomes problematic because the overall spacing is now wider.”

Could the XX1 concept be further expanded with a revamped HammerSchmidt or high-performance, internally geared setup, though? Hilton doesn’t rule out that possibility but says it’s not imminent.

Either way, XX1 sounds awfully appealing on paper. And after a brief test ride inside SRAM’s Schweinfurt facility, in Germany, it certainly seems to work. We’ve been promised parts for testing in the near future so we’ll know for sure soon.