Hubsmith is one of those companies which you probably haven’t heard of, even if you’ve used its products before. The Taiwanese manufacturer churns out 50,000 hubs a year from its base in the Fenyuan District of Taichung, making products for all riding disciplines.

Some are more garish than othersOnly committed bike dorks will get excited about this sort of thing, but Hubsmith’s latest range of freehubs features faster pick-up courtesy of a little design trick. Pick-up is one of those things that doesn’t really matter in the greater scheme of things, but which affects how your bike feels. Simply put, it’s the amount you need to turn your cassette via pedalling before the freehub ratchet engages and transmits torque to the rear wheel. The number of teeth in a ratchet determines how quickly the hub picks up, and while it’s easy enough for a hub designer to increase that number, doing so in isolation means making the teeth smaller, which of course makes them weaker too.

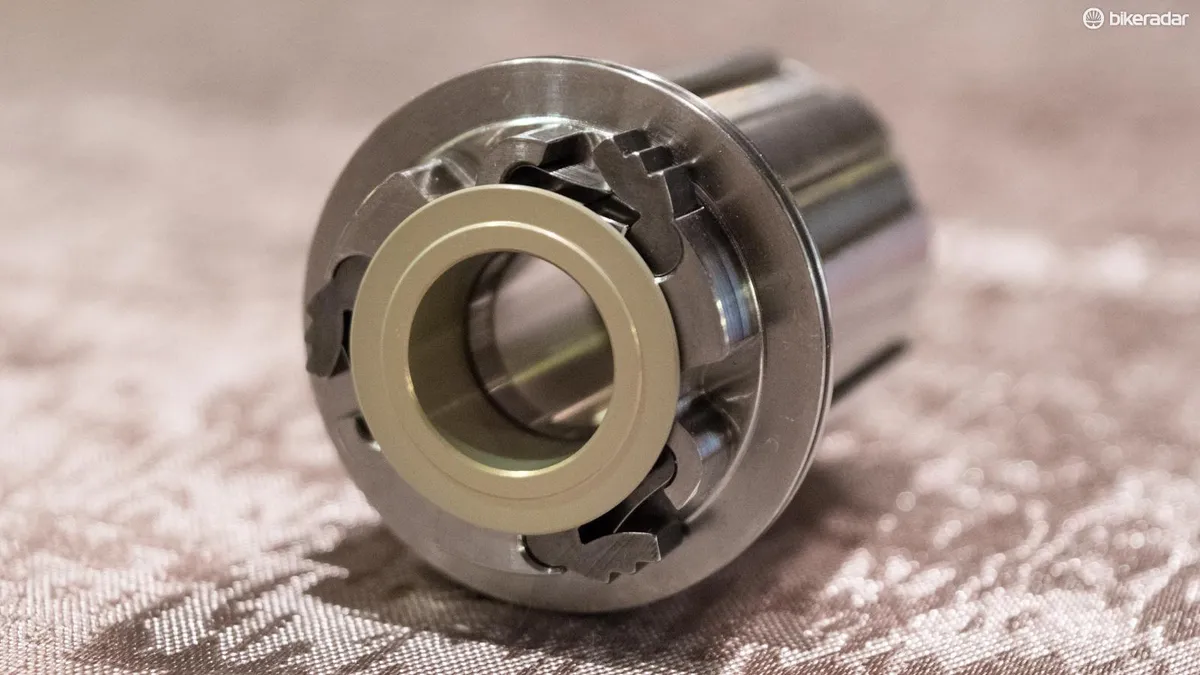

We love hubs. Mmmm hubsTo address this, Hubsmith’s latest freehubs use stepped pawls that engage with three teeth at a time, spreading the load and reducing the force applied to each individual tooth. It’s a simple but clever idea, and it has the added benefit (if you’re into that sort of thing) of making a cool buzzing sound. Does the new freehub design offer Chris King’s angry-bee acoustics on the cheap? Perhaps not quite, but we think it sounds pretty good. Judge for yourself from the clip below.

null

Another new feature from Hubsmith is a new steel wear plate for Shimano-fit freehubs, essentially an anti-bite guard the like of which we’ve seen from other manufacturers. The low splines of Shimano’s freehub design are subject to huge stresses from the cassette, which is why Shimano makes most of its freehubs from hard steel.

Steel is heavier than aluminium of course, so many aftermarket manufacturers choose to use the latter for their freehubs, despite its susceptibility to damage from cogs digging in to the splines. An anti-bite guard attempts to address this, with minimal weight gain.

BikeRadar fondled the new freehub on a media tour of Taiwan hosted by TAITRA, the Taiwan External Trade Development Council. TAITRA is promoting the Taipei International Cycle Show, which takes place from March 2-5 2016. We’ll be posting more highlights from our travels over the coming days.