With the coming tide of disc brakes to road bikes, many consumers are also naturally expecting thru-axles to accompany them given their more secure connection. That may very well come to pass but in the meantime, there are still countless bikes with traditional open dropouts – not to mention lots of substandard quick-release skewers.

Topolino Technology wheel company founder and engineer Raphael Schlanger has proposed an intriguing alternative that combines features and benefits of both systems.

"With the UCI regulations regarding lawyer tabs and the growing popularity of road discs, I think the time is finally right for a robust and solid wheel attachment that is also truly quick," Schlanger said.

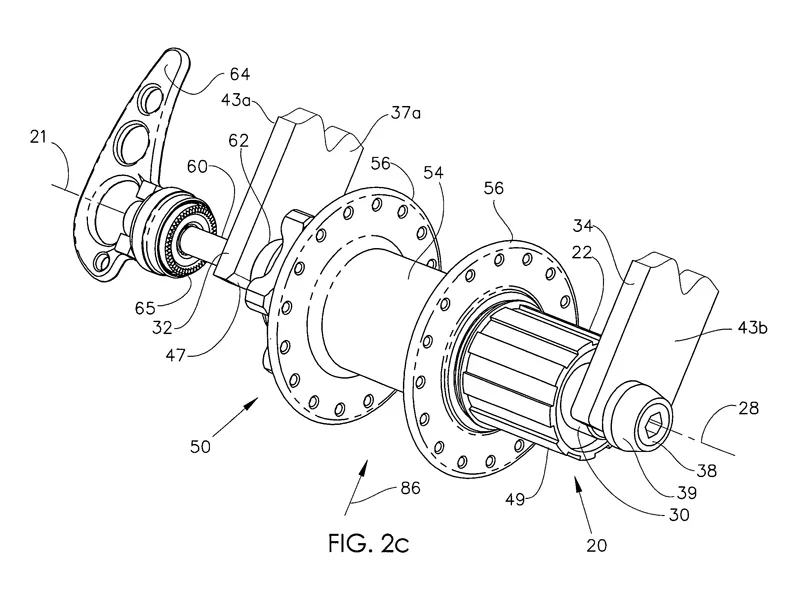

Schlanger's system – called SPEEDrelease – features a threaded anchor that retrofits to one fork tip or rear dropout and a dedicated skewer is then fed in from the other side. When it's all screwed together, Schlanger says it's just as secure as a thru-axle.

The clever part about SPEEDrelease is how quick it appears to use. The skewer slides back and forth within the hub shell but only as much as needed and can't be removed by accident, the threaded anchor is fixed in place, and the hub is quickly guided in place just like with traditional open dropouts.

null

Video: Topolino Technology SPEEDrelease

Overall, the system seems well engineered and very quick and easy to use. It's also lightweight at a claimed 140g for a front hub, skewer, and anchor.

Schlanger even has a SPEEDrelease system developed for rear wheels using a similar – but more radical – concept. Here, the skewer is again captured inside the hub and threads into a fixed anchor. However, Schlanger's design calls for a split rear hub whereby the freehub body (and cassette) is semi-permanently bolted to the driveside dropout. Each half of the driver mechanism stays securely fixed within the hub shell and freehub body so there are no small parts to lose.

The rear SPEEDrelease design is much more radical and features a split hub whereby the freehub body - and the cassette - stays attached to the dropout

At least conceptually, this variant seems to hold more benefit. Users wouldn't have to deal with the drivetrain at all when removing the rear wheel, which would not only make for a cleaner process but one that would be legitimately quicker to use.

Even so, Schlanger's hopes for widespread industry adoption seem fraught with peril. While SPEEDrelease is easily adapted to existed frames with no modifications required, the hubs are proprietary and currently only offered by Topolino. There are also some practical questions such as how SPEEDrelease-equipped bikes would be mounted on roof racks.

Perhaps tellingly, SPEEDrelease seems to have gained little traction since Schlanger's original patent for the idea was granted more than 13 years ago.

"Yes, this system requires a proprietary axle set up, although it can usually be adapted to an OEM’s existing hub shell design," Schlanger told BikeRadar. "Our goal is to get the hub makers and OEMs involved. It’s especially elegant when the adapter is molded directly into the fork end."

Despite the challenges, Schlanger still feels his SPEEDrelease can go toe-to-toe with the common thru-axle.

"The 15mm thru-axle is a clumsy and overkill solution for road forks," he said. "I think some product managers are simply going with something they already know, rather than truly examining the needs of a road bike application."