One year on from our first look at the fruits of Campagnolo’s Disc Brake Project, I was finally able to ride the finished product in early May, and my initial impressions are quite positive.

Campagnolo now has hydraulic road disc brakes covering four mechanical-shift and two electric-shift groupsets: Potenza, Chorus, Record and Super Record, plus Record EPS and Super Record EPS.

Campagnolo claims its new road disc brakes stop faster than Shimano and SRAM in the dry and the wet, with less hand force required.

Ergopower H11 carbon levers with two pad-engagement options

Ergopower H11 is the name given to the all-carbon levers that comprise the high-end of the range and are compatible with all of the above. Potenza will come with H0 alloy levers and, for now, Chorus EPS isn't compatible because it uses different wiring.

Ergopower H11 maintains the current shift lever positions of both mechanical and EPS, and typical Campagnolo style, design and ergonomics. The greatest challenge for the engineers was squeezing in the hydraulic master cylinder, and the resulting levers are 8mm taller than the rim-brake originals.

Magura helped develop the hydraulic cylinder and oil flow system, since Campagnolo had no previous experience in that area. The cylinder was designed to be very small and use mineral oil, with a bleeding port situated vertically on top. (Shimano uses mineral oil; SRAM uses DOT fluid.)

The extra 8mm hood height offers an additional hand position. The brake levers retain their familiar double curved profile, but now with a subtle outward curve in the lower part of the lever to help purchase when on the drops.

The brake levers have two settings for pad engagement. There is adjustment via a 2.5mm hex key socket on the inboard side of the lever body. A clearly marked two-position cam controls the long or short travel settings, with the long position allowing about half of the lever’s full travel before the pads engage.

The brake lever and long shift lever can also be adjusted for reach in tiny increments with easily accessible 2.5mm hex bolts.

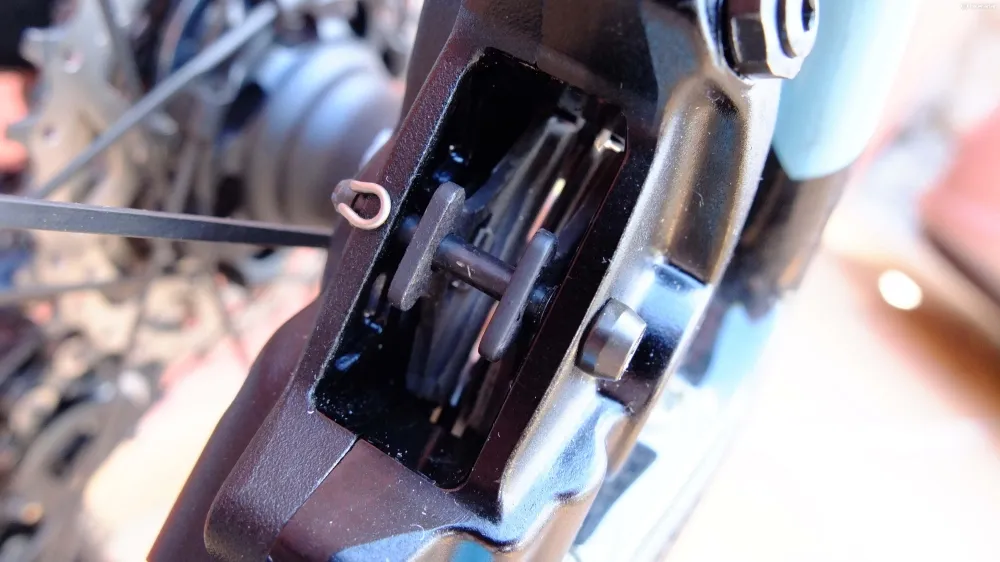

Size-specific calipers, organic resin and claimed class-leading stoppage

Campagnolo believes that altering the spacing of a disc caliper with an adaptor isn’t mechanically secure or stable and adds unnecessary weight, and has therefore designed one forged aluminium caliper for 140mm rotors and another for 160mm rotors. They’re designed to fit every flat mount frameset currently available and mounting screws are available for the rear caliper in 19, 24, 29, 34, 39 and 44mm lengths.

The calipers have lightweight 22mm diameter pistons made from phenolic resin, which was chosen for its thermal insulation qualities to avoid heat transfer from the pads. There’s no mechanical pad spring, but the magnetic spring used delivers uniform performance over time and has a faster return speed, Campy claims.

Campagnolo said one major reason its disc brakes took so long to release was refining the brake pads and to not compromise on safety. The resulting organic resin compound used is extremely heat resistant, with uniform and consistent braking, whatever the temperature and weather conditions, the company claims.

Campagnolo’s patented noise and vibration reducing system comprises a bonded layer on the back of each pad, giving purchase and an element of cushioning for the piston/pad interface.

The pads are mounted in steel and have been tested to exceed all current competition, Campagnolo claims, with smooth roll back to the optimum distance to avoid drag. Each pad has a small ramp to guide the rotor when fitting the wheel and a visible wear indicator, which when reached, gives an audible warning too.

One obvious change from last year’s prototypes are the disc rotors, which are now perfectly round rather than wavy and feature rounded edges that have been tested to not cut skin.

Designed for AFS Centerlock fitting hubs, they come in 140mm or 160mm diameters and are steel with an aluminium carrier. The rotors, pads and hydraulic calipers are the same across the range.

Compared to 'two unnamed competitors' (read: Shimano and SRAM), Campagnolo claims that its disc brakes decelerate 23–26 percent faster in the wet and between 14–55 percent faster in the dry, while requiring less hand force than either.

H11 weights

Array

The equivalent new Shimano Dura-Ace Di2 R9170 hydraulic groupset weighs 2,389g.

Because disc-specific framesets have different geometry, Campagnolo found it needed to realign the chain rings a little further outboard and therefore disc-specific cranksets with specific rings that aren’t interchangeable with conventional Campagnolo rings have been created.

The carbon H11 crankset is intended for use with the five higher end groupsets, and an alloy Potenza H0 crankset is available too, with both retaining their existing 145.5mm Q-Factor.

A customer who already has a Potenza groupset would need to buy a new crankset, levers and brake calipers to convert it to a disc groupset.

Ergopower H11 hydraulic component pricing

Array

The price for the levers and calipers also includes a pair of rotors, a bleed kit, 250ml of mineral oil and the necessary screws.

Combining the above disc-specific components with the existing groupset’s front and rear derailleurs, cassette and chain will create a coherent disc groupset, although you could of course pick and choose parts to suit.

Example prices for each complete disc groupset are as follows :

- Potenza DB: €1,580.53 / £1,339.43 / $1,610

- Chorus mechanical DB: €2,343.25 / £1,985.81 / $2,135

- Record mechanical DB: €2,632.71 / £2,231.11 / $2,385

- Record EPS DB: €4,063.05 / £3,443.26 / $3,835

- Super Record mechanical DB: €2,878.82 / £2,439.68 / $2,610

- Super Record EPS DB: €4,396.62 / £3,725.95 / $4,230

The first of the disc groupsets to become available will be H11 mechanical DB, which is scheduled for May this year. Potenza DB follows in June and H11 EPS DB in July.

First ride impressions

My test ride route in Gran Canaria was mainly up or down, with several sections of rolling terrain thrown in. Campagnolo provided a Sarto carbon frame with Campagnolo Super Record mechanical DB components and 160mm rotors at both ends.

As you’d hope for a new bike, everything was silent, smooth and slick. On the numerous drags and small climbs that littered the first half hour there was no evidence of pad rub on any of the bikes in our group.

The new H11 hoods feel very similar to previous Campy offerings; they are not too fat, not too tall or bulky. They suited my large palms well, but they’re not likely to alienate the smaller handed rider either.

Without adjusting the brake levers’ reach, they were perfectly positioned to operate comfortably with no extra finger extension.

The hoods are beautifully grippy and well cushioned, proving equally effective with gloves or bare hands.

We descended countless switchbacks and variously profiled bends, giving the brakes a thorough workout.

I began with the pad contact setting at its short position and in this mode the pads began to engage very soon after the lever was pulled, maybe within about a quarter of its travel. From that point, the power on tap was both plentiful and easily modulated, just over less of the lever’s total travel.

Differing pitch steepness and varying distance between bends allowed the chance to try braking in different ways. With the thermometer around 28℃ / 82℉, the brakes soon heated up.

Several brakes, including mine, developed a low-pitched hum when being worked hard in to corners, but it was never high-pitched or squeaky, and it didn’t affect the brakes’ effectiveness when next applied.

Campagnolo said that in its tests the new discs were significantly better than the competition in just this scenario, when some competitor brakes suffered reduced function when pulled hard, released, then pulled again.

The brake operation was very consistent and demonstrated great power. I only got to ride them in the dry, so will have to reserve judgement on them in the wet until another day.

I switched the pad contact point from short to long and immediately found it more to my personal liking. Depending on your riding style and experience you might too, but having the option of adjusting between the two is a unique selling point. (Shimano has a subtle pad-contact adjustment and SRAM has a more pronounced adjustment. Neither have the two-setting feature.)

With almost twice as much lever travel before the pads began to bite I found it easier to quickly gain a good feeling from the brakes and gained more confidence because it felt more familiar.

No amount of hooning about unsettled the new discs and on the flatter run back to town I got to try out the alternate position on the tops of the hoods. The taller horn makes a decent hand hold and provides a lot of grip even for large hands. I found that it allowed for extended riding in a flat-forearms position, where it felt more comfortable and relaxed than on standard levers.

Trying to make a direct comparison to my experience of SRAM and Shimano hydraulics is tricky without riding them back to back in similar conditions, and of course there will always be the variables of rotor and pad type, plus frame and wheels to consider. But with hundreds of hours spent riding bikes equipped with disc brakes from Campagnolo’s main competitors, I'm confident in saying that these compare favourably.

From first lever movement to pad contact, there’s a positive feeling, unlike the loose-feeling free travel I’ve experienced too often with Shimano levers in particular.

From pad contact and initial bite, I found a progressive and consistent amount of braking force that was a cinch to modulate, even with my brake levers on the opposite side to usual.

Throughout a lengthy, hot descent with numerous corners that came one after the other, there was no fade and the brakes gave me tremendous confidence.

Functionally, Campagnolo’s disc brakes are at least as good as their main rivals and in some areas — depending on your tastes — arguably better. I loved the ergonomics of the hoods and levers, and especially their adjustability, allowing riders to customise operation to suit their preferred style.

I'm looking forward to some longer term testing back home on familiar roads and in all conditions, but as first impressions go the brakes are impressive and were worth the wait.