Mountain bike rear suspension may appear to come in a baffling array of different designs. Each one is claimed to offer superior performance for one reason or another, usually backed by an array of baffling acronyms and marketing spiel. But if you really boil it down, there are essentially just three or four basic layouts, each with their own pros and cons.

Suspension nerd Seb Stott talks through the process of fine tuning your suspension for the perfect balance of support and suppleness

Here I’ll go through all the major layouts — and a few variations too — explaining how they work and their potential advantages or shortcomings.

Then I’ll define the major design concepts that are collectively known as suspension kinematics, these include: anti-squat, brake jack, and leverage rate, as well as the important concepts of Instant Centre and Centre of Curvature. I’ll explain what they mean, how they interact and use some real-world examples to shed light on how they affect the way a bike actually rides.

First off, let’s take a look at the four main designs, followed by a few which don’t fit neatly into those categories. The terms used here in bold will be defined and explored in detail later in the article.

Mountain bike suspension designs explained

1. Single pivot

This is the simplest suspension design. Here the rear axle is connected to the main frame by a swing arm, with no pivots in-between. The axle moves in a constant arc, centred on the pivot point.

In the case of a true single-pivot, the shock is connected directly to the swingarm — a design made famous by Orange Bikes. The simplicity of the design makes for easier maintenance of the pivot bearings.

One possible shortcoming of this design is that it offers little control over the leverage curve. True single pivot bikes are generally pretty linear — the force required to move the rear wheel through its travel does not “ramp up” towards the end (to resist bottom out) as it does with a more progressive design.

2. Linkage-driven single pivot

A linkage-driven single pivot design still uses an uninterrupted swingarm, connecting the rear axle directly to the mainframe. However, it incorporates some form of linkage to drive the shock. This allows the designers to manipulate the leverage curve and so control the frame’s progressivity (how much the suspension firms up towards the end of the stroke).

On a Scott Gambler, or any recent Evil, for example, the linkage is driven from the front of the swingarm.

Kona, Cannondale and Commencal — among others — typically use a visually different design, which sees the shock driven from a pivot (or flex-stay) located above the rear axle.

This looks similar to a four-bar (Horst-link) design, so is sometimes referred to as “faux-bar”; but the rear axle is still connected to the main pivot via a simple swingarm, so this is just another form of linkage-driven single pivot.

3. Horst-link (four-bar)

Horst-link (aka four-bar) suspension — as used by Specialized, Norco, and newer Transitions (as well as many others) — is marked out by a rear pivot located below the rear axle on the chainstay (rather than the seatstay as with the “faux-bar”).

This means the rear axle is not directly connected to the mainframe, and so moves in a path which is defined by its Instant Centre and Centre of curvature, which may move as the suspension cycles through its travel. Depending on the position of the Instant Centre, the effect of braking forces on the suspension (known as anti-rise) can be reduced relative to a single pivot design.

As I’ll explain later, this can afford designers more control over the levels of anti-squat throughout the suspension’s travel, as well as reducing the effect of braking forces (known as anti-rise) on the suspension, with the aim of improving sensitivity.

4. Twin-link (virtual pivot point)

These use a rigid rear triangle, articulating on a pair of short links which connect it to the mainframe. It actually works in a similar way to a Horst-link design — imagine moving the Horst-link’s chainstay pivot much closer to the mainframe and you have the basis of a twin-link system. The only real difference is the length of the lower link. The Fuji Rakan illustrates this lack of distinction, like a missing link between the two styles.

As with the Horst-link design, here the axle’s direction is tangential to a moving instant-centre, while the related concept of the centre of curvature, or 'virtual pivot point', defines the way in which the axle path curves through its travel.

Some, such as Santa Cruz’s VPP system, use links that counter-rotate (turn in opposite directions), while many others, such as Giant's Maestro system, have links that co-rotate (turn in the same direction).

As we'll see later, the way the centre of curvature migrates as the bike moves through its travel is quite different for each configuration. In fact, twin-link or horst-link bikes with co-rotating links often exhibit anti-squat behavior that's very similar to a single-pivot bike. While counter-rotating links can produce an anti-squat profile which peaks in the middle of the travel, which may be desirable in terms of balancing pedal efficiency against pedal kickback. This distinction between counter-rotating and co-rotating links is more important in terms of suspension kinematics than the arbitrary distinction between Horst-link and twin-link designs.

Example of Pole's moving instant-centre

A few notable exceptions:

5. Trek’s ABP system

This design is essentially a linkage-driven single pivot, except that Trek uses a concentric dropout pivot at the rear axle. This allows them to mount the brake caliper to the seatstay rather than the chainstay.

Because the seatstays rotate less around the disc rotor than the chainstays as the suspension cycles, the effect of braking forces on the suspension (known as anti-rise) is significantly reduced.

In other words, Trek’s design works like a linkage-driven single pivot in terms of pedalling forces, but like a Horst-link in terms of braking forces. It’s kind of a hybrid.

6. Yeti’s Switch Infinity

This system uses a lower pivot which slides up and down on a pair of vertical shafts, along with an upper link which rotates clockwise (if viewed from the driveside) as the suspension compresses.

The lower pivot acts like the rear pivot on the lower link of a traditional twin-link design, except that this pivot moves vertically in a straight line rather than a curving arc centred on the forward pivot point.

Imagine you could make the lower link of a traditional twin-link bike infinitely long and horizontal. Then its rear pivot location would move up and down in a straight, vertical line with no curvature to its path at all. This is essentially what Yeti has simulated with its linear sliders (hence the name).

What’s the point of all that? Well, Yeti claims this allows them to get the kinematics to behave how it wants all the way through the travel.

On paper, at least, there’s nothing drastically different about Yeti’s suspension kinematics compared to some regular twin-link designs, although it's managed to weight the anti-squat towards the sag point where it’s needed most, while minimizing pedal-kickback elsewhere in the travel.

I'll explore this trade-off later in the anti-squat and pedal kickback sections. However, it’s not true that the Switch Infinity design has a particularly unusual or rearward axle path, as some media outlets may have claimed.

7. High-pivot

High pivot bikes typically use a single pivot design, but the pivot point is placed much higher than normal. This would result in unacceptably high levels of pedal-kickback if it wasn’t for the use of an idler pulley, which routes the chain line up past the pivot point.

The advantage of this design is two-fold. First, it provides a rearward axle-path. This in itself can help the rear wheel to deal with square-edge hits and contributes to the overall pedaling efficiency of the bike. Second, because the chain passes right by the pivot point, there is next to no pedal kickback. This further improves suspension sensitivity.

The disadvantages of high pivot designs include increased drivetrain drag and maintenance thanks to the idler pulley, high levels of anti-rise due to the high pivot point, and a rear-centre length which increases as the bike sits into its travel — this can have some odd handling characteristics.

So what do anti-squat, anti-rise and all those other terms mean?

Let’s define some of the technical terms used to describe suspension kinematics.

I’ll look at how they compare between different designs using a few individual bikes as examples.

What is Instant-centre? (IC)

The instant centre (IC) dictates the direction in which the rear axle, wheel and everything attached to it, moves at a given point in the travel. Any such point - including the tyre contact patch or the rear axle - moves in a direction at right angles (tangentially) to the line connecting that point to the IC.

For single-pivot bikes (including linkage-driven varieties), the IC is simply the main pivot point. It doesn’t move; it’s fixed on the mainframe. Therefore, the rear axle is constrained to move at right angles to the main pivot at all times, so it moves in a constant arc centred on the pivot.

In a Horst-link or twin-link design, the instant centre ‘floats’ at the point of intersection of the lines drawn through the pivots of the two links (yellow circles), which are connected to the mainframe as shown by the blue circles in the diagrams below.

The instant centre (blue circle) is located at the intersection of the lines drawn through the pivot points

As you can see, the instant centre moves as the bike cycles through its suspension travel.

This video below shows how the IC migrates as the suspension cycles through its travel. In this case, where the two links both rotate clockwise, the IC moves downwards as the suspension moves through its travel.

Pole's moving instant-centre

The location of the instant centre helps define the levels of anti-squat, pedal-kickback and anti-rise at a given point in the travel.

Because the instant centre moves as the suspension cycles through its travel, Horst-link or twin-link designs can afford their designers greater control over these parameters throughout the travel.

What is Centre of Curvature? (CC)

The centre of curvature is the effective pivot point of a twin-link or horst-link design. Imagine a drawing compass where the rear axle acts as the pencil and the CC is the other end stuck into the paper — it defines the radius of curvature of the axle path.

If you draw a line from the axle to the IC, then move the axle a small amount through the travel, then draw that axle-to-IC line again, the point at which those lines intersect is the CC.

For single-pivot bikes, the CC is at the main pivot point, which is also the IC. For twin-link or horst-link bikes, the IC moves relative to the mainframe. In some cases, the CC moves too. In others it doesn’t.

This Gif shows the position of the CC for a twin-link bike in which the links co-rotate. The CC (yellow circle) doesn't migrate significantly in this design - this is typical of co-rotating links. Notice that at any point in the travel, a straight line drawn from the axle to the IC will pass through the CC. This line is known as the swingarm line. The axle path and anti-squat profile of this bike will resemble a single pivot design with a main pivot located at the point of the CC (see the anti-squat section below).

For bikes with links which counter-rotate (e.g. VPP), the CC moves significantly. This results in varying curvature of the axle path, and anti-squat values which peak somewhere in the middle of the travel range.

At a given point in the travel, the CC always sits at some point along the swingarm line, connecting the rear axle to the IC. Therefore, when calculating anti-squat at a given point in the travel (see below), the IC or the CC can be used interchangeably, as they both agree on the tangential direction of the axle. But to see how the anti-squat changes throughout the travel, the position and movement of the CC is helpful to look at.

What is Pedal bob?

Every time you push down on the pedals, the bike accelerates. This acceleration causes the rider’s weight to shift backwards and compress the rear suspension — just like in an accelerating car.

This happens with every pedal stroke, so the bike oscillates, or bobs, as you pedal. This oscillation is known as pedal-bob and it’s driven by the rhythmic nature of pedalling.

This movement wastes energy; the suspension dampers convert this energy into heat rather than propelling the bike forwards.

As the rider puts weight on the pedals they exert a downwards force on the bottom bracket. This causes the suspension to compress, so the bottom bracket moves downwards as the pedals pass three and nine o’clock, then it rebounds back up as they reach six and 12 o’clock.

So if you moved with the bike and looked at the cranks from the side, the pedals wouldn’t move in a circle, they’d move in an elliptical (oval) path because the bottom bracket moves up and down as the cranks turn.

This means the rider has to push the pedals further per revolution than they would if there was no pedal bob, yet the rear wheel still turns the same amount. This extra distance is proportional to the wasted energy.

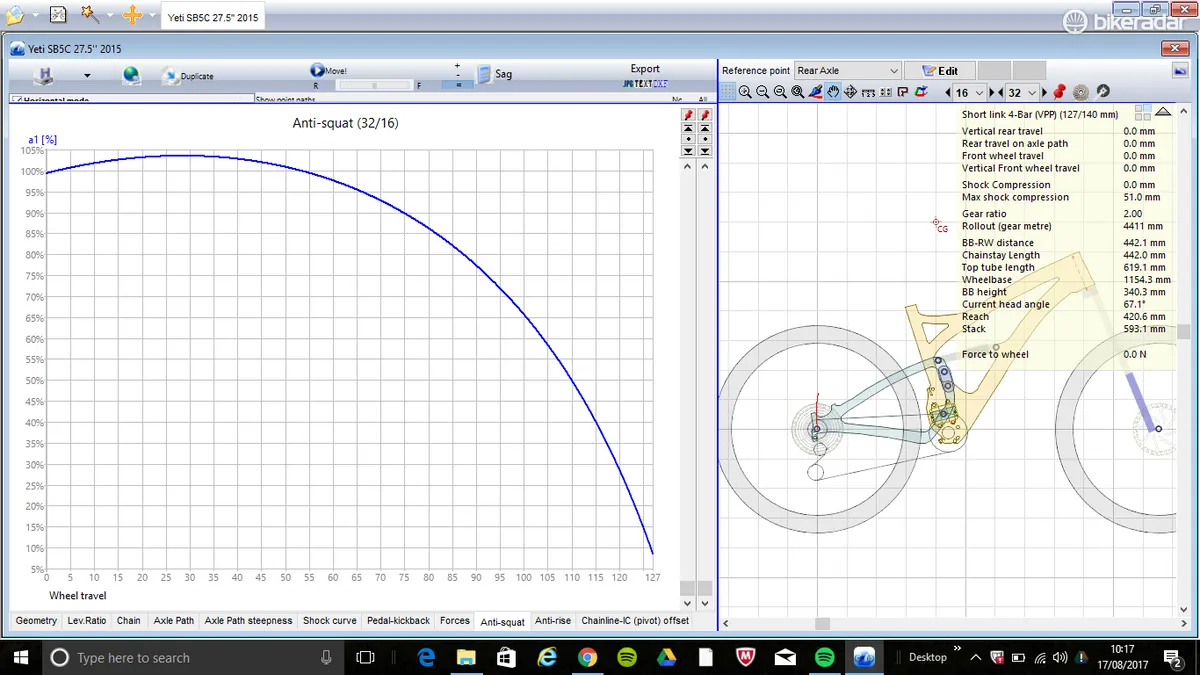

What is Anti-squat?

Anti-squat is basically a measure of how much the suspension resists pedal bob. This is a large part of what makes one bike pedal more efficiently than another.

So as the squat force (due to acceleration) acts to compress the rear suspension under power, the anti-squat force acts to counteract this. This force comes from two sources: the driving force from the rear wheel, and the chain-pull force.

The driving force is little discussed but easy enough to understand.

For any bike, think of the effective swingarm as a straight line connecting the rear axle to the instant centre. This is known as the swingarm line. By definition, this line will also pass through the centre of curvature, but for simplicity we’ll just refer to the IC here.

The driving force pushes through the swingarm line. The force is composed of the traction force propelling the bike forwards, plus the compressive force generated by the chain tension. If the instant centre is higher than the rear axle - so the swingarm line is angled upwards - a component of this driving force acts to push the mainframe upwards when pedalling, counteracting its tendency to squat down under acceleration.

The chain-pull force comes from the tension in the chain, which generally also pulls the rear wheel downwards relative to the mainframe, and so acts to hold mainframe up, countering its tendency to squat under pedalling load.

Thinking of it another way, (for most bikes) the cassette moves up and away from the chainring as the suspension compresses, therefore the tension in the chain resists this motion by pulling the swingarm down.

The amount of driving force anti-squat force depends on the angle of the swingarm line, while the amount of chain-pull anti-squat depends on the angle of the chain line relative to the swingarm line. The total amount of anti-squat can be worked out by the intersection of the swingarm line and the upper chain line. (see the diagram below.)

The point where they intersect is the key. A third line can then be drawn from the rear contact patch through this point of intersection. This is known as the anti-squat vector, and its gradient defines the amount of anti-squat.

Comparing this line to the centre of gravity and the front contact patch tells you how the anti-squat force compares to the squat force due to acceleration.

In simplistic terms, 100 percent anti-squat would imply that the squat and anti-squat forces cancel out exactly. In theory, this results in zero pedal bob.

If the anti-squat vector is higher than the centre of gravity when it’s directly above the front contact patch you have more than 100 percent anti-squat. If it’s below the COG when it’s above the front axle you have less than 100 percent anti-squat.

Importantly, the anti-squat percentage is independent of how hard you pedal. If you pedalled twice as hard, you’d accelerate twice as fast, and so the squat force would double. At the same time, the anti-squat force would double as there would be double the tension in the chain. So the anti-squat percentage would remain the same.

So why aren’t all bikes designed to have 100 percent anti-squat? Wouldn’t that mean an end to pedal bob?

Well, as you may have guessed by now, it’s not that simple.

For starters, there is no way to accurately estimate the position of the rider’s centre of gravity (it varies depending on the rider, and he or she moves about when riding). Even if you could estimate the rider’s centre of gravity, the position of the bike’s front centre affects the percentage anti-squat. That changes with the frame size, so you’d need to account for that too. Most bike designers don’t.

For most bikes, the amount of anti-squat also depends on what gear you’re in.

The exception to this is the case of a bike where the CC is exactly in line with the top of the chainring. Otherwise, the choice of rear sprocket will give different amounts of anti-squat, as the intersection of the chain line and the swingarm line will change.

Different chainrings upset things too, with smaller chainrings resulting in higher anti-squat. This is an argument in favour of multiple chainrings, as higher anti-squat is generally beneficial when climbing.

Another complication is that, for most bikes, the levels of anti-squat vary as the bike moves through its travel — sometimes by a lot — so how much dynamic sag you run will affect anti-squat and therefore pedal-efficiency. So changing spring pressures, or riding up different gradients, will result in different anti-squat percentages.

Let’s imagine for a minute that you could design for just one frame size, one gear, one point in the travel, and for a rider whose centre of gravity was fixed. In that case you could design a bike to resist squat exactly, if the power was applied smoothly via a motor. That’s why it is possible (though not necessarily advantageous) to design a motorbike that resists acceleration-induced squat almost entirely.

But mountain bikes are not motorbikes. When pedalling, a rider’s weight moves up and down slightly as their legs turn. This introduces another oscillation-driving force, which causes the bike to bob more than the acceleration force alone, especially when pedalling stood up.

For this reason, many bikes have more than 100 percent anti-squat to help counter the combined squat forces from acceleration and the rider’s weight movement. Because downhill bikes are designed to be pedalled standing up only, they often have anti-squat levels far higher than 100 percent. The Scott Gambler, for instance, has anti-squat values of around 170 percent at sag thanks to a very high instant centre. For reasons we’ll discuss later, other downhill bikes such as Speecialized’s Demo, have anti-squat values far lower than 100%.

In theory, if you could pedal perfectly smoothly without jerking up and down, bikes with more than 100 percent anti-squat would rise upwards, like an inchworm, rather than squat down when pedalling. This has led some suspension analysts to say that 100 percent anti-squat is the Holy Grail for the best possible efficiency.

But the jerky bodyweight movements of the rider mean bikes need a bit more anti-squat to overcome this, and because this force changes depending on the rider’s pedalling style, and isn't necessarily in-phase with the acceleration squat force, there’s no way to say what the best anti-squat value is.

So don’t be fooled by any marketeer claiming their bike has “optimised pedal-efficiency.” It’s much more complicated than that.

What is Pedal kickback?

There can be a downside to high levels of anti-squat.

The chain-pull force relies on the cassette moving away from the chainring as the suspension compresses — this is known as chain growth. Most of the time, the cassette will simply rotate forwards to allow the chain enough slack for the suspension to compress.

However, if the cassette can’t spin forwards because the rear wheel is locked up, or is spinning more slowly than the cassette needs to in a sudden compression, the crank will be forced to rotate backwards. The movement of the crank in the case of a non-rotating cassette is known as pedal kickback. The angle through which the cranks rotate relative to the mainframe as the suspension compresses can be calculated using suspension software, or measured.

For a visual demonstration of pedal kickback watch how the crank moves in this gif.

The more chain-pull anti-squat a bike has, the more pedal kickback it generates. These terms can roughly be thought of as two names for the same thing. So for bikes that don’t use an idler pulley, the amount of pedal kickback is proportional to the anti-squat.

For bikes with high pedal-kickback values, its effect can occasionally become noticeable - especially on rough tracks with lots of sudden impacts or when hitting bumps with the rear wheel locked up. (See my Orange Alpine 6 review)

It’s also noticeable when climbing. As the chain is always under tension when pedalling, the anti-squat by definition resists the suspension’s movement. So bikes with high anti-squat can be harsh and unreactive when pedalling over bumps.

For many riding situations, pedal kickback in itself is not something you’re likely to notice. But the more chain growth/pedal kickback you have, the more the chain, cassette and derailleur cage have to move in order to allow the suspension enough slack chain to react. This can have a detrimental effect on suspension sensitivity, especially when using a clutch mech.

But does this matter? Just ask Aaron Gwin. When he won the 2015 Leogang World Cup without a chain he was heard remarking to his team mate Troy Brosnan: “The suspension works so good with no chain!” While by no means a scientific assessment, this passing comment highlights the effect chain-pull can have on suspension sensitivity. If you want proof, try riding chainless.

So there’s a balance to be struck here; more anti-squat generally means greater pedal-efficiency, but tends to mean worse sensitivity.

This is where Horst-link and twin-link designs have a potential advantage over single-pivot systems.

All such designs feature Instant Centres which migrate as the suspension moves through the travel. Some, particularly those with counter-rotating links, can be designed such that the centre of curvature migrates significantly as well. In that case, the angle of the swingarm line varies with travel in a way which isn’t possible with a single-pivot. This makes it possible to have high levels of anti-squat near the sag point (where it’s needed to resist bob), while having less anti-squat, and therefore less pedal kickback, elsewhere in the travel.

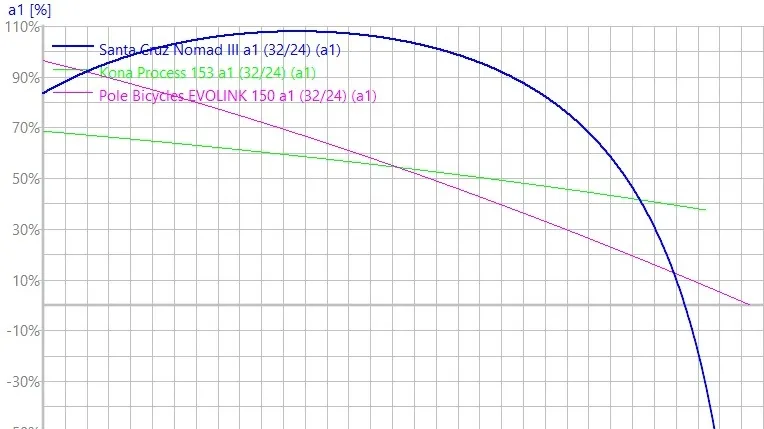

This is by no means true of all multi-link bikes, but those with counter-rotating links (e.g Santa Cruz) as well as some Yeti designs, boast anti-squat values that peak between 20–45 percent travel where it’s needed most — see graph. This bell-shaped anti-squat profile is typical of twin or horst-link designs with counter-rotating links. The result is good pedalling efficiency throughout the pedalling zone, with minimal extra pedal kickback further into the travel.

Also notice the the similarity in anti-squat profile between the single pivot Kona and twin-link Pole. The Pole's anti-squat drops off more quickly due to a more rearwards CC (behind the chainring) and because the CC moves downwards very slightly through the travel.

In cases where the links co-rotate, such as Specialized’s FSR layout, the centre of curvature doesn’t move significantly relative to the mainframe throughout the travel. This means the rear axle moves in an arc with a constant radius about the CC, much like a single-pivot, resulting in similar anti-squat behavior. Namely, the anti-squat usually drops off throughout the stroke. The steeper the anti-squat drops off, the less pedal kickback there will be towards the end of the stroke, but the more the pedaling efficiency will be affected by dynamic sag.

However, the centre of curvature can be designed to sit in a position which would be impractical to place a physical pivot (such as within the radius of the wheel, or in the middle of the front triangle). In this sense, the designers can produce kinematic behavior which would be difficult, in practice, to replicate with a single pivot.

Without redesigning your bike, you can tune the amount of anti-squat it has by swapping chain rings.

Bigger rings will result in reduced anti-squat but less pedal kickback, or vice versa. More simply, riding over rough terrain in the smaller cassette cogs (and bigger chain rings if you have multiple) will result in less pedal kickback. So shift into the harder gears before dropping into a rough descent for maximum sensitivity and minimal feedback.

High-pivot bikes bypass this catch-22. The idler means they exhibit virtually zero upper chain growth or pedal-kickback. Yet, due to the high IC, they still have significant levels of anti-squat thanks to the driving force alone.

What is Anti-rise? (aka brake jack)

Another concept which depends on the instant centre and affects suspension performance is anti-rise — commonly referred to as brake jack. This is basically the effect of the rear brake force on the suspension. It works a bit like anti-squat, but in reverse.

Under braking, the rider’s weight shifts forwards due to deceleration, which causes the rear suspension to rise or extend. However, the force going through the rear brake calliper acts to compress the suspension, pushing the mainframe down. This resists the bike’s natural tendency to want to lift at the rear, so the bike stays more level under braking.

If you compress the rear suspension while the rear wheel stays still, the calliper will move around relative to the disc. If you pull the rear brake when riding forwards, the braking torque from the calliper acts to compress the suspension by an amount proportional to this movement relative to the disc.

Check out how the brake's position moves in relation to the disc rotor in this gif.

High levels of anti-rise are generally thought to make the suspension feel firmer and less reactive over bumps, resulting in a harsh feeling when braking. At the time of writing, the author is not convinced of the significance of this effect.

On the other hand, anti-rise also helps the rear suspension sit deeper into its travel, so it’s debatable whether high anti-rise values result in more or less traction under braking.

Currently, the general consensus in the industry is that anti-rise is bad. As a result, some companies go to great lengths to reduce its effect.

The amount of anti-rise depends on the extent to which the calliper wants to move around the disc, and this depends on the position of the instant centre.

Imagine a line between the rear contact patch and the IC: the shallower the gradient of that line, the lower the amount of anti-rise. This is called the anti-rise vector and can be used to calculate the percentage anti-rise in just the same way as the anti-squat vector in the diagram above.

Here, more than 100 percent anti-rise implies that pulling the rear brake only would cause the rear suspension to compress, while less than 100 percent anti-rise implies it would extend.

Horst-link or twin-link bikes with roughly parallel links (e.g. Specialized’s Demo or Rocky Mountain’s Slayer) have an instant centre that’s very far forward.

Therefore, the anti-rise vector sits at a shallow angle, resulting in low levels of anti-rise. Bikes with instant centres placed high up and rearward (e.g. Scott’s Gambler) have more anti-rise.

Trek’s ABP design sees the brake calliper attached to the seatstay, rather than the chainstay. The seatstay moves on an arc which is defined by a floating instant centre, like a Horst-link, which is further forward of the main pivot, so anti-rise is reduced relative to a chainstay mounted calliper.

Back in the day brake arms were used to similar effect — they reduce anti-rise by limiting the brake’s effect on the suspension.

Just like anti-squat, the amount of anti-rise is a trade-off between preserving the bike’s geometry and preserving the suspension sensitivity. No bike is completely independent of braking forces and it’s debatable whether those braking forces are necessarily a bad thing. So take any marketing claims along these lines with a pinch of salt.

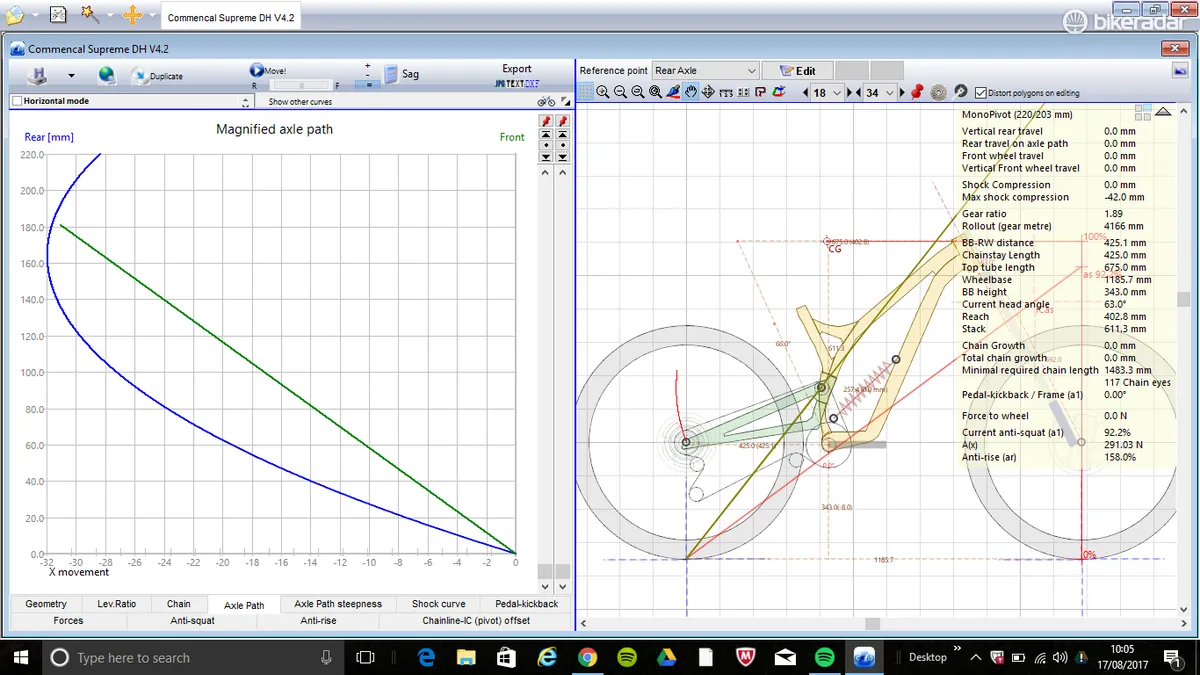

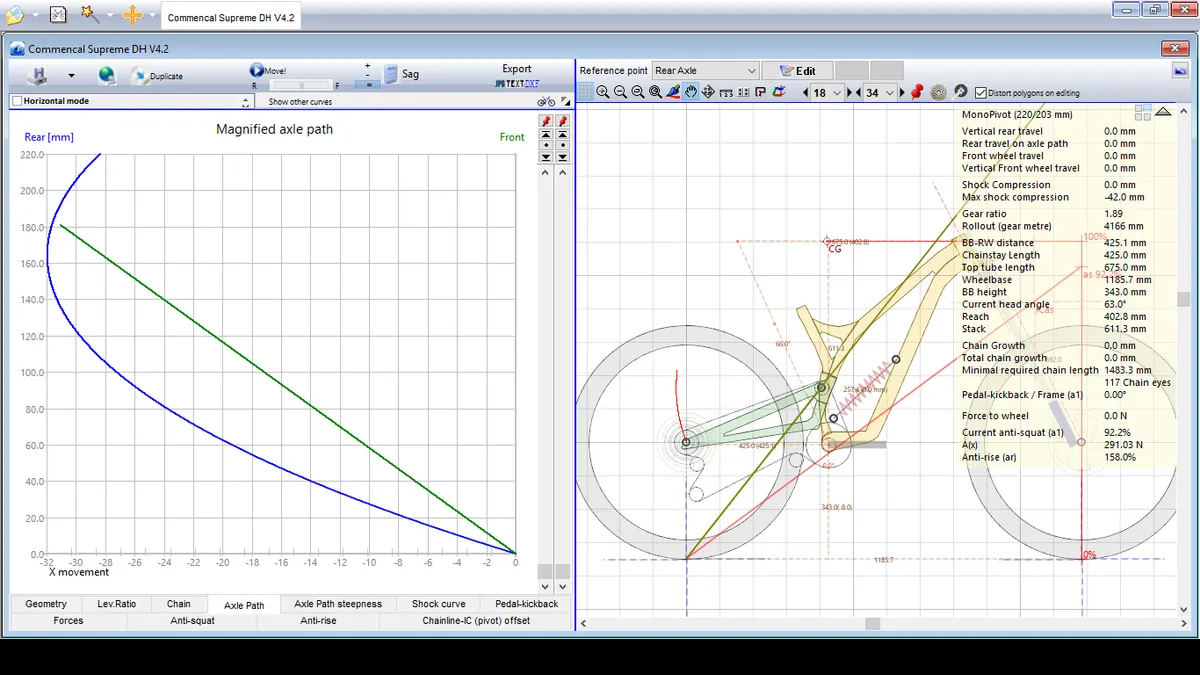

Axle-path explained

The axle path is basically the line the rear axle takes as the suspension moves, measured relative to the mainframe. The direction of the axle path at any point in the travel is at right angles to the swingarm line, which connects the axle to the instant centre, via the centre of curvature.

Therefore, you can think of anti-squat purely in terms of axle path - the more the axle path moves away from the bb, the more anti-squat. This is very much the same as saying that a higher instant centre results in more anti-squat, as described above.

A more rearward axle path may also help a bike to absorb certain bump forces for reasons unrelated to the chain. But for most bikes, the axle path only moves rearwards by a few millimetres at most.

Once again, high pivot bikes are a notable exception. Their axle path moves significantly rearwards throughout the travel.

It makes intuitive sense that a rearward path allows the wheel to move out of the way more easily when faced with large bumps. The force produced by these is rearward as well as upward (the force vector points in the direction at right angles to the point on the wheel where it contacts the bump).

Therefore, it stands to reason that a more rearward axle path will be better able to absorb these large bumps, because the axle moves in a direction that’s better aligned with the bump force.

For an analogy, it’s useful to look at forks with different head angles; the head angle defines the axle-path of the front wheel. Slacker head angles, and therefore forks, tend to absorb kerb-sized bumps more smoothly but are more prone to flex and binding when pushing vertically downwards in the car park or when landing to flat.

The same thing is happening with a high-pivot bike — large bumps push the axle in the direction it wants to go. The flex and binding issue doesn’t apply to the rear suspension as they use a linkage rather than telescoping through bushings.

Think of it another way. A rearwards axle path means the rear wheel travels backwards relative to the mainframe as the suspension compresses. This means the wheel moves more slowly relative to the bump and so moves up and over it more slowly too.

However, there is still some debate about how significant an effect this really is and there’s little evidence to suggest that it helps the bike carry more speed over bumps, as some have claimed.

Having said that, one study demonstrated that a full suspension bike required 30–60 percent less power than a hardtail to ride over simulated rough terrain in a lab.

So, if high-pivot suspension absorbs bumps more effectively, it stands to reason that those bumps will rob the bike of less forward momentum, but this is largely unproven.

Either way, for bikes without an idler pulley, this is all fairly academic. In that case, the potential bump-absorption advantage of a (slightly) more rearward axle path is negated by the increase in chain-growth and anti-rise they produce.

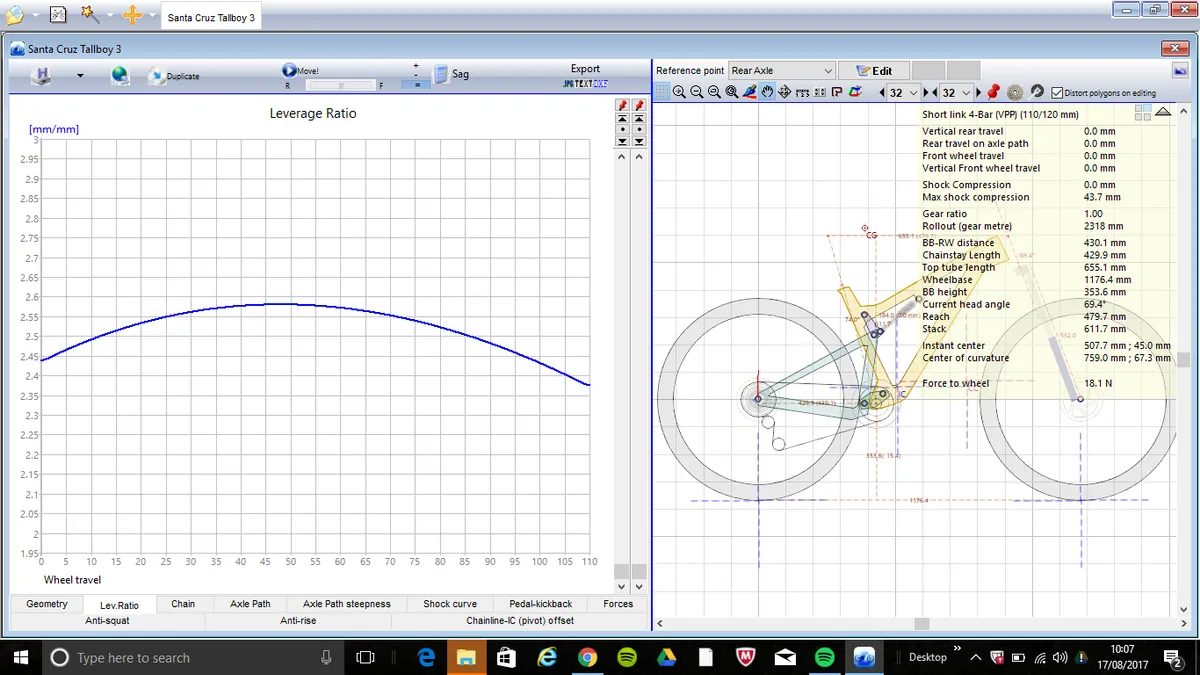

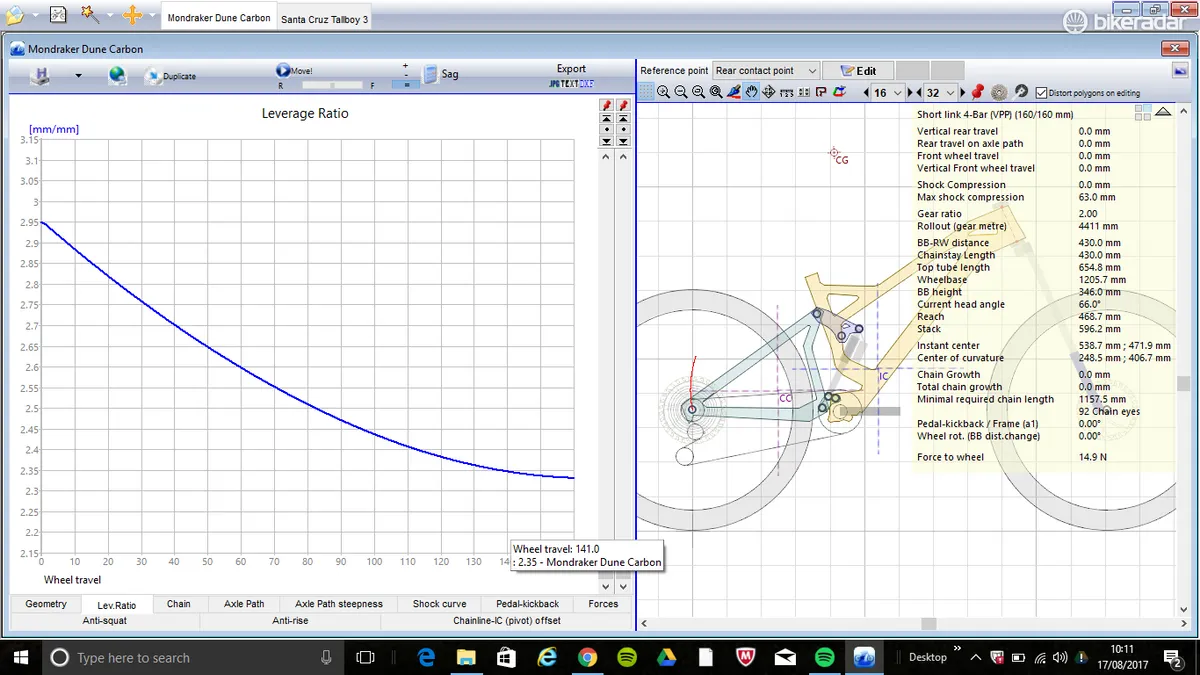

Leverage curves vs. spring curves

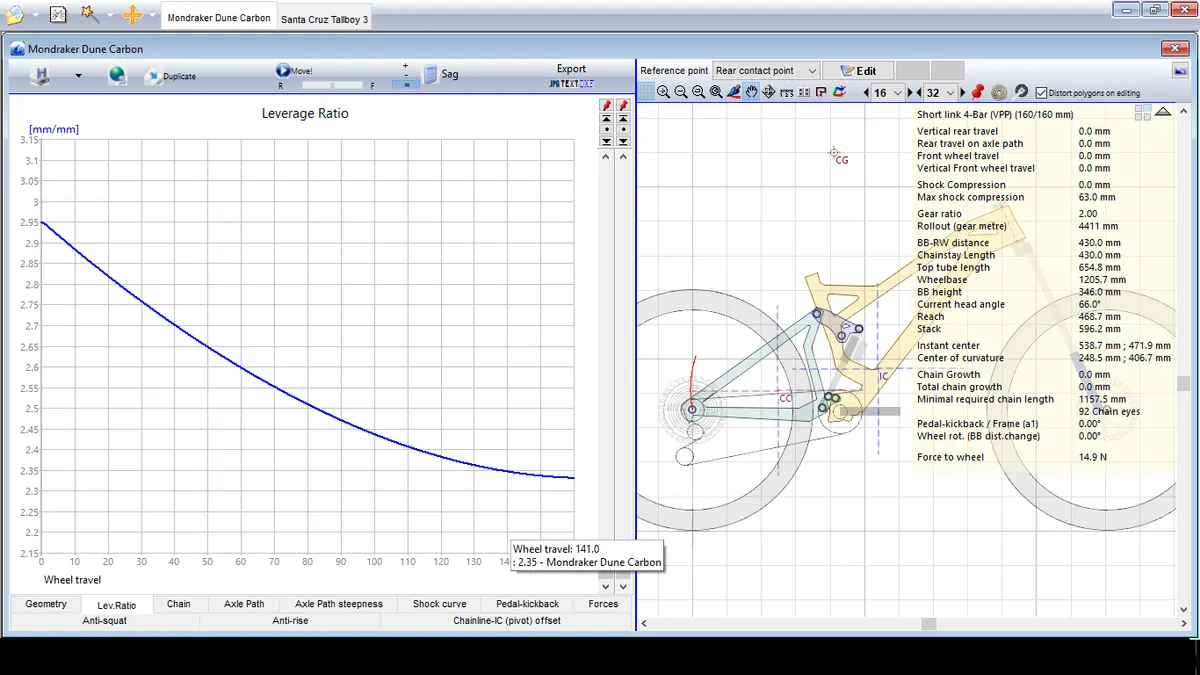

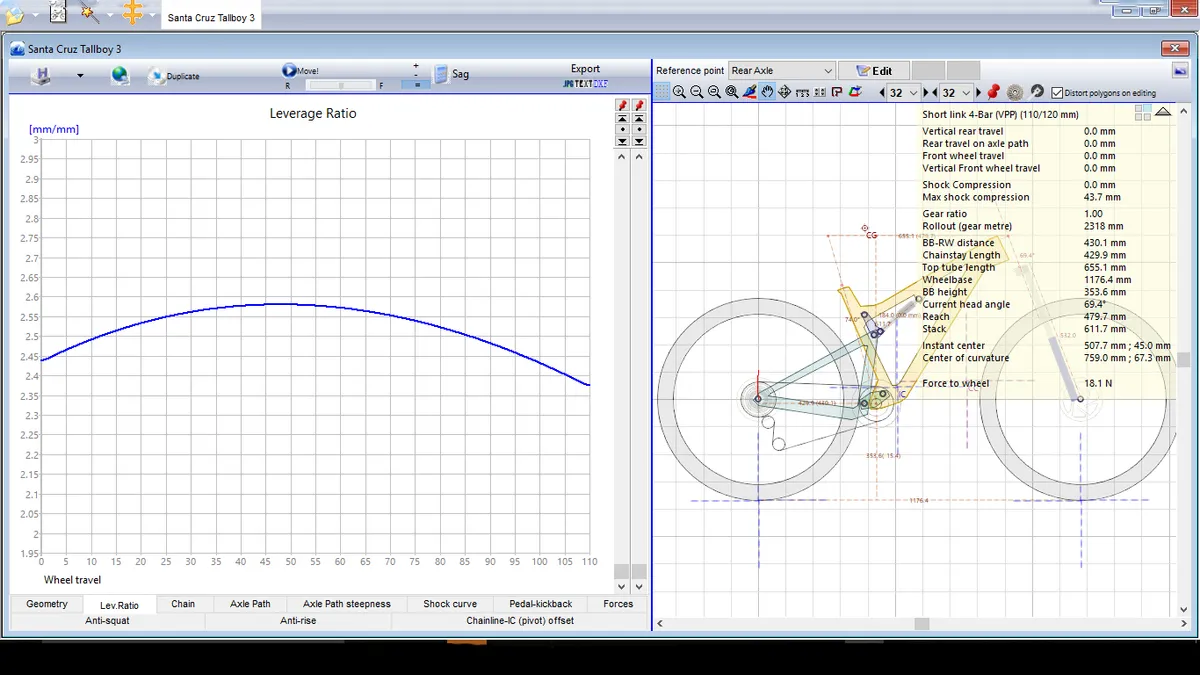

Arguably the most important aspect of suspension kinematics in terms of ride feel is the leverage curve — the way the leverage ratio changes through the travel.

The leverage ratio is the ratio between the distance the rear wheel moves vs. the distance the shock moves as the suspension cycles.

The average leverage ratio is therefore the ratio of rear wheel travel to the stroke of the shock. Bikes with higher average leverage ratios (short stroke shocks for the travel) may have an advantage in terms of sensitivity because there’s more leverage to overcome the friction in the shock.

On the other hand, high leverage ratios demand higher spring pressures and higher forces in the damper. There’s also generally less oil inside the damper to deal with heat on long runs. As a result, bikes with lower average leverage ratios (longer stroke shocks for a given travel) tend to be more reliable and more consistent.

The most important aspect of the leverage curve is not the average ratio but how the leverage ratio changes throughout the travel. The higher the ratio, the easier it is to compress the shock, so bikes that start with a high leverage ratio and end with a lower one result in a progressive suspension action.

It’s counter-intuitive, but for a bike to be progressive the leverage graph slopes downwards as you go through the travel.

By comparing the leverage ratio at sag with the leverage ratio at bottom-out, the fame progressivity can be calculated as a percentage. With a coil shock (which has a constant spring rate), the amount of progressivity is defined by the leverage curve alone. With an air shock, the end-stroke progressivity can be fine-tuned (to some extent) with volume spacers.

The overall firmness of the suspension at the wheel is known as the wheel rate. This is a function of the shock’s spring rate and the leverage curve — both of which may vary throughout the travel. A leverage ratio which decreases towards the end of the stroke has a similar effect on the wheel rate as a spring rate that increases towards the end of its stroke. Both result in a progressive suspension action.

A linear leverage ratio with a progressive shock may provide a similar wheel rate (overall progressivity) as a progressive leverage ratio with a linear shock. But these two setups will still offer different characteristics.

For starters, fitting a very progressive air shock (full of volume spacers) to a bike with a linear or regressive leverage curve will result in faster end-stroke rebound due to the high spring force deep in the travel.

A progressive leverage curve also generates more resistance from the damper towards the end of the stroke, so both spring and damping forces are used to resist bottom-out. Whereas, in the case of a linear leverage curve, only the spring force ramps up towards the end of the stroke.

The percentage progressivity doesn’t tell the whole story, what matters most is where in the travel the frame is progressive. In other words, the shape of the leverage curve.

For example, bikes such as the Mondraker Dune and Canyon Sender exhibit what’s known as a “hanging” leverage curve. That means they have a high leverage ratio at the start of the travel to soften the initial stroke and quickly drop to a lower ratio in the middle of the stroke to add support after sag. This is particularly relevant when using an air shock as they tend to be firmer in the beginning stroke and softer in the mid-stroke, relative to a coil.

The opposite case is a kind of humped shape, where the maximum leverage occurs in the middle of the stroke. As you might expect, this results in a firmer beginning stroke and a softer mid-stroke than the “hanging” curve.

Combined with an air shock, this lack of mid-stroke support can result in a wallowing feel in compressions, as well as increased pedal-bob — it’s not just anti-squat which affects pedal-efficiency.

The leverage curve may still be progressive towards the end of the stroke, but this is not where the support is needed with an air shock. Bikes with this shape of leverage curve may work better with a coil spring. Bikes which lack support in the mid-stroke tend to require higher levels of compression damping to resist mid-stroke wallow, but this negatively affects sensitivity throughout the stroke.

This kind of 'humped' leverage curve is the main gripe I had with the 2016 Nukeproof Mega 290 and to a lesser extent the Santa Cruz Hightower. It’s also the main reason why the new Santa Cruz Nomad has been designed with a ‘hanging’ rather than ‘humped’ leverage curve, thanks to the shock being mounted to the lower, rather than upper, link.

How progressive your bike needs to be is entirely personal — it depends on the rider’s strength, terrain and riding style.

Thanks to modern air shocks, progressivity is easily tunable by the end user, but the bike’s leverage curve still plays a huge role in how the bike feels, particularly in the mid-stroke, and that’s something which can’t always be remedied with shock setup.

Summary

Whether single-pivot, Horst or twin-link, it’s the details of pivot placement that make all the difference. Bikes with the same basic layout often display very different kinematics and ride feel, therefore it would be ridiculous to say that one design performs better than any other.

Single-pivot suspension offers simple reliability, but provides designers little control over the bike’s kinematics. Adding linkages makes it possible to manipulate the frame’s leverage curve and progressivity, while Horst or twin-link layouts can boost control over the pedalling and braking behaviour too, especially if the links counter-rotate.

But is that an advantage? It depends entirely on what the designers do with that control, because it’s not always for the best.

While the shock setup remains the most important aspect of rear suspension performance, that’s not to say that a good shock tune can make up for a flawed suspension design. Particularly if a frame has excessive chain growth or a leverage rate that’s not supportive enough for the rider’s needs. In that case, the shock setup will be at best a sticking-plaster for poor design.

Having said that, the suspension characteristics that work best for you will depend on how you ride. For example, one criticism levelled at true single pivot bikes is that they are generally pretty linear, but that may suit some riders who prefer a plush feel.

Similarly, those who like to hammer down rough terrain may not like a bike with too much pedal-kickback, while some might like the pedal-efficient and interactive feel that comes with high levels of anti-squat. It’s largely a matter of taste and that probably explains why we still see such a vast array of designs on the market.

The Author would like to thank Alan Muldoon (MBR); Timothy Stevens (Scott); Leo Kokkonen (Pole), and Chris Porter (TBC) for taking the time to discuss the finer points of suspension theory with me - at length and on several occasions. I'm just beginning to get my head around it now.