Chances are you don’t know much, if anything, about Verge… but you should.

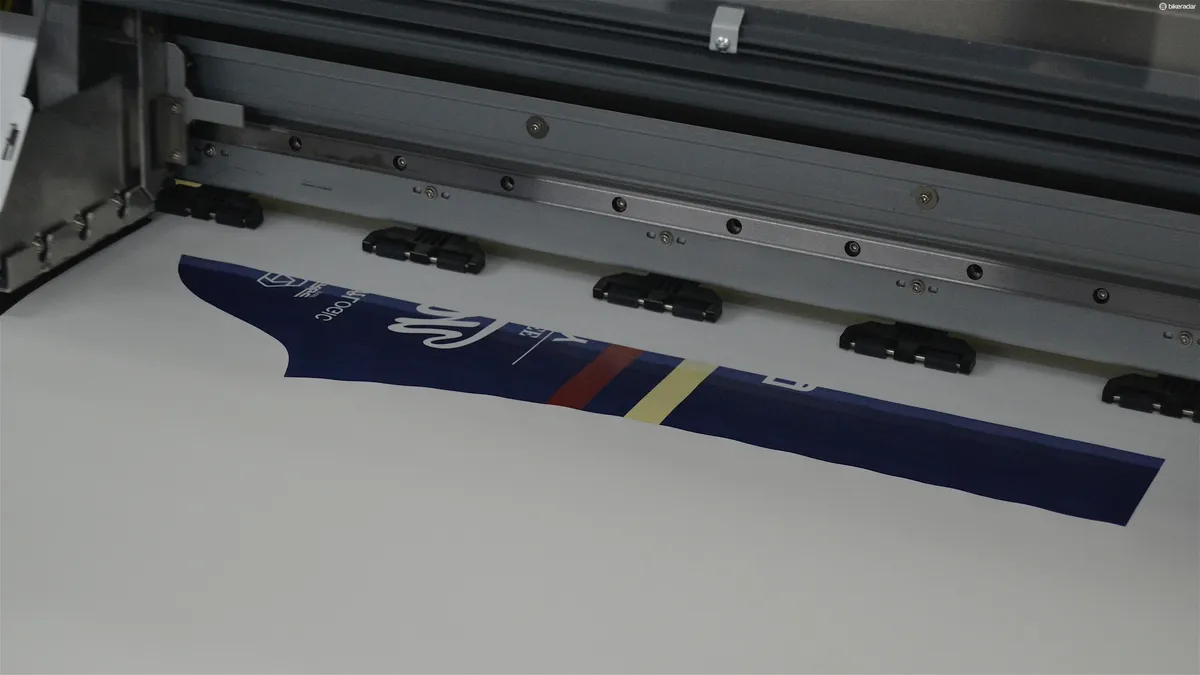

Here is a company quietly revolutionising the custom cycle clothing business by delivering technically advanced gear to guaranteed four-week turn-arounds and with no minimum order thanks to a carefully judged mix of new technology and old fashioned handcraft.

This year it’s supplying the Topsport-Vlaanderen team in the Women’s WorldTour.

Verge was founded 18 years ago in Poland by American Mike Magur. At the time he didn’t speak much Polish, but following a few years racing there he knew about the region’s huge textile heritage, with each town having its own speciality.

During BikeRadar’s visit to the factory in Jelenia Gora, 10km from the Czech border, Magur tells us how it all began:

Customisation options are legion for all the key garments — how about nine different options on one model of bibshort alone

“When I was a junior I had a Polish friend who coached and mentored me. He'd defected from communist Poland and been held in a detention centre before moving on to America. He still had lots of friends and contacts in Poland and was able to put me in touch with a pro team.

“I raced here for the first time in 1989, then moved here in ’91. One day I was on the start line of a race and it was getting chilly so I asked my girlfriend to pass my arm warmers from my kit bag. She couldn’t find them and then I hear this English voice say ‘Here, you can use some of mine.’ He was a Brit, out here making clothing. We became friends and when I went back to the States I started importing his clothing and selling it.

"I raced for another two years back in the States before I realised I had more chance of being successful in business, making and selling cycling clothing.”

Most of the key people at Verge are cyclists and racers, "I believe it really makes a difference," says Magur. The company president, Janusz Smolinski, isn’t a racer but he was the very first person Magur hired — they tell a charming story of an interview with almost no shared language, after which Janusz rolled up his shirt sleeves and helped Magur retile the office — and they built the company together.

Now, nearly two decades on, the collection includes some of the most advanced gear we’ve seen in custom ranges.

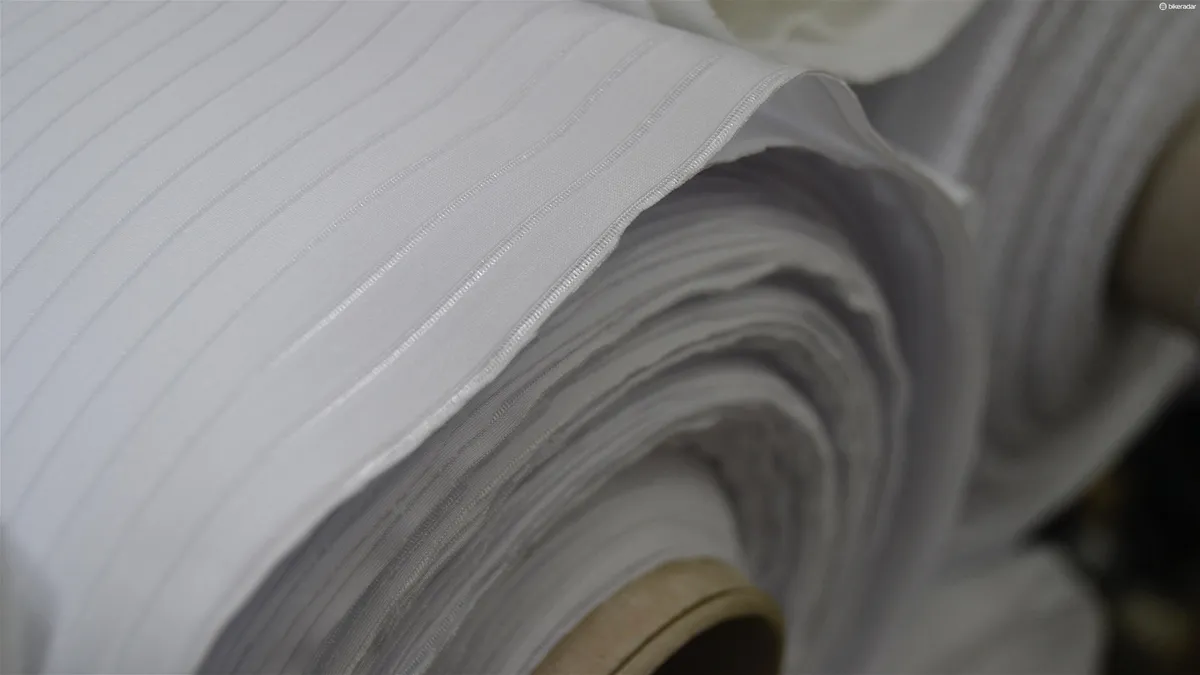

Both the Carrera road race and Go Fast time trial skinsuits, for example, use a super-fast lightly ribbed fabric which creates a boundary layer of air next to it, smoothing overall airflow. Seam placement too is carefully calculated and the TT suit’s zip is moved to the back to completely smooth the torso.

The bad weather gear is also note-worthy. The Defend jacket is claimed to trump the famous Castelli Gabba by being fully waterproof and windproof while remaining stretchy and breathable, all thanks to a fabric that includes a membrane as well as a DWR treatment — most jackets like this rely just on the latter. While Verge admit that the Defend is slightly less breathable than a Gabba, it says it’s more weatherproof and its performance doesn’t deteriorate with washing.

Customisation options are legion for all the key garments — how about nine different options on one model of bibshort alone, plus a choice of three lengths. Individual jersey naming is now available too and custom sizing is on the way.

Added value

From the start, the plan was always to own a factory rather than outsource the manufacturing. “It prevents a lot of mistakes and confusion. It gives us control,” says Magur.

That last word — control — comes up a lot. In an industry infamous for vague and shifting delivery dates, it’s what allows Verge to always hit its exceptionally rapid four-week promise.

It uses over 300 different fabrics and 80 different zips from over 200 suppliers

John Dempsey is the UK and Ireland agent for Verge. “In four years and over 400 orders, I’ve never had a late delivery,” he says. “When people first come to us and we tell them it’s four weeks, they don’t really believe it but they always have their gear on time. We’ve never lost a client for any reason other than a paying sponsor joining a team.”

Magur explains the personal motivation for this timeliness and the technology-driven solutions that enable it: “I couldn't stand seeing my friends at races and telling them I'm really sorry I said it would be here for this weekend but it will be another two weeks. That's at the very foundation of why we set up our own facility. We put a lot of effort into our proprietary scheduling and production systems and we have a full-time programmer.

"Each week we have a certain amount of production capacity and it’s represented in our system as points. Those points are allocated to jobs and each item accounts for a certain number of points — a 90-point job might be 250 arm warmers or 30 skinsuits — so we know what will be made and when, giving an exact delivery date. The system shows the job status, down to the exact percentage of the order that has been cut, printed or sewn.”

The points based system is also what allows Verge to do away with minimum orders — you can order a single pair of custom socks if you want to. Magur says this is of particular help to clubs and teams with few women or youth riders in need of specific items.

However, Magur says that technology can’t replace human skill and Verge employs 120 staff in Poland: “We focus a lot on people. We treat them really well so they stay with us. It isn't a push button process, every garment is touched by at least 50 different people. That really helps us to work with smaller clubs. We've experimented with laser cutting and other advanced production methods, and every time we've introduced them we've gotten slower. If you want to produce small custom orders you need the skilled people.”

In a typical week, Verge handles some 250 orders consisting of around 3,000 items. It uses over 300 different fabrics and 80 different zips from over 200 suppliers.

Even the delivery stage has added value. For a small fee, Verge will pack orders into bundles for each rider to save a lot of hassle when it arrives. In some countries it’s even possible for a delivery to be split after it passes customs and then delivered individually.

Verge also runs online team shops where riders can place their orders directly and re-order as needed. Needless to say, club kit managers love this.

Check out the photo gallery to see the various stages of kit production and the Verge range at www.vergesport.com