Rolf Timmerman, the director of FFWD, is buzzing with pride over what his firm has achieved in its short eight-year history. Based in the unassuming small-town of Zwolle, about an hour from Amsterdam, this tightly run wheelmaking company has seen significant success in a short time.

While other companies may bombard you with technical stories, wind tunnel data and performance-gain boasts, Timmerman claims that FFWD is simply about bringing the best-built wheels it can to market and backing that up with service and support levels no one else can offer.

"Every part of our wheel-building process is completely done by hand; [during] the rim manufacture in our facility in Asia the carbon is hand-laid. When the rims arrive here they’re are assembled by our team of wheel builders, finished and tensioned and stressed all by our highly trained staff."

This is, of course, exactly the kind of bluster and marketing hype you expect manufacturers to spout. But as we spend a day within the building we see every piece of the process come together – and it's hard not to walk away impressed.

When rims arrive at Zwolle, they're checked and visually inspected before heading out to a test lab to be X-rayed and approved

As the rims are unpacked and visually inspected, we see some being rejected because of the smallest imperfections – a few millimetres of flat rather than shiny surface on a rim wall, for instance. After the first inspection, but before they go into the construction of a wheel, they’re shipped a few doors down to be independently non-destructive tested, with rims analysed and X-rayed for any potential flaws. Again, the smallest flaw and the rim is set aside and left unused.

Related: Inside the Cinelli and Columbus factories

The destructive testing, Timmerman tells BikeRadar, is done in Asia – but obviously you can break as many as you make, so that’s a sample test only. By contrast, non-destructive testing is used on every tubular rim FFWD receives.

“This way we can be absolutely sure that every rim that gets built into a wheel is as good as it can be – our reputation is built on quality and we won’t lose that,” Timmerman goes on. “The independent testing is expensive, but we think it is worth it.”

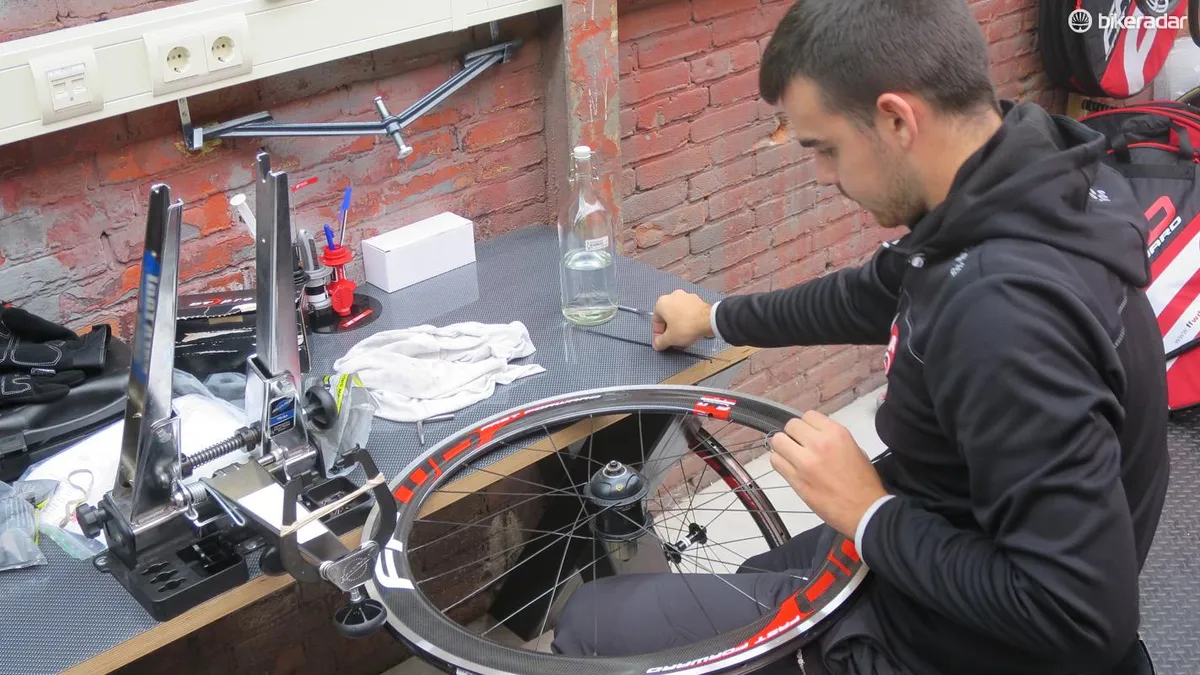

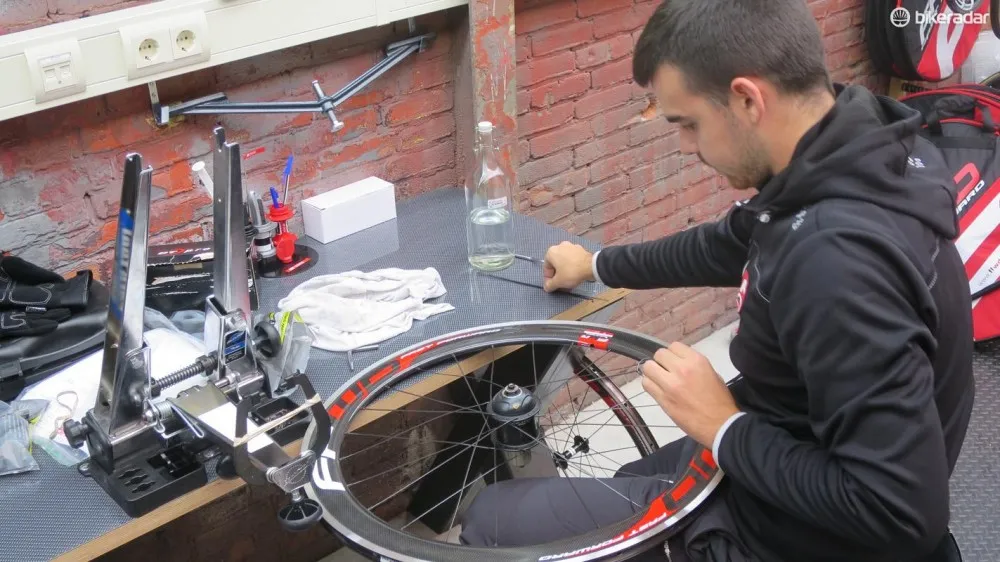

They get through a fair few spokes over in Zwolle

FFWD’s head of product development Marcel de Jager gives us the tour of production and an insight into what goes into the rim design. "We like to control every part of the process, and by assembling by hand we have experts who know how wheels work and what makes a good wheel," he enthuses.

"Luckily everyone here, be it in the office, or in assembly or service, are all riders – we have ex-Dutch champions, an Eastern Bloc Olympian, and ex-professional riders too," de Jager goes on. "Maybe the chance to be able to ride and test what they build is a big draw, but we’re certainly glad to have them."

Telepathic wheel knowledge

We also meet Roman Storcel, master wheel builder. Not only does he build new designs into wheels, advising on the best way to lace them and refine the designs, he has an almost telepathic knowledge of wheel strengths.

The spokes are stressed by hand, in between checking the wheels and tweaking the spoke tension

We watched Storcel build a wheel from scratch, tensioning it up (all by hand) and getting the alignment perfect in all directions before stressing the spokes – first on each side with a hydraulic press, before putting it back into the wheel jig for a little more fettling. The final stressing is done by hand, with Roman grabbing fistfuls of spokes and listening for the telltale pings and creaks as they settle.

Related: FFWD F4R-C wheelset - first look

Onto his next wheel and, as Storcel is again stressing the spokes, his ears prick up and he tells us that this particular rim is no good. It looks perfect to these eyes, but he quickly pinpoints the slightest of deviations in the carbon sidewall above a spoke bed and insists that this one won’t do.

I ask de Jager why FFWD insists on even the most menial parts of the process being done by hand – surely a machine lacing the rims and hubs would save time, wouldn’t it?

Roman Storcel listens and makes fine adjustments in the blink of an eye

"One of our friends who produces wheel building machines was of the same opinion,” de Jager replies, “so we said, yes, okay, lets test it to see.

“The machine did do a good job of building the wheel under its standard tolerances. Then we asked if it could work to the tolerances we expect of the wheel builders, and the computations and corrections the automated system was having to make couldn’t achieve what our builders can – and to get close the machines were taking just as long.

“So it not only makes little sense for production; financially its ineffective too – and also, we couldn’t talk [any more] about how ‘handmade in Holland’ is our key factor,” de Jager says.

Fast reflexes

De Jager goes on to claim that because everything is handbuilt and completely controlled within FFWD’s building, it enables the firm to react quickly and make running changes – and that everybody is involved, every step of the way.

As an example, he highlights that FFWD had braking performance issues with some of its full-carbon rims. Not unusually, in the dry they were good, but in wet conditions or when they got hot the performance left something to be desired.

"We developed and designed the next-generation rim, where the main structure is 3k carbon over a unidirectional core for strength – but then we used a 1.5k weave with a high TGC (heat resistant resin) on the brake surface,” says de Jager.

FFWD's DARC rim shape, it's claimed, offers a stiffer shape than a standard airfoil

“The extra texturing of the 1.5k gives more friction for better braking and the increase in surface area helps dissipate heat better; it’s also less prone to noise, which some carbon rims can suffer from," de Jager adds.

"Now with the new F3 wheels, which are designed for climbing (1195g a pair for the tubulars and 1395g for the clinchers), we needed a lightweight strong rim but it needed to be as good going downhill as it was up. So we developed a new brake surface for these – we’ve included basalt in the brake surface to aid friction and strength, but under the skin we have a fine layer of copper.

"It (copper) is a great heat conductor, so it's there to absorb the heat from the rim material and dissipate it quickly meaning that even on the longest descents the rim won’t overheat, and your ability to brake won't suffer."

FFWD also builds one-offs in the factory – this is a special-order PowerTap wheelset

Despite its oft-repeated commitment to handbuilt quality, our impressions were that FFWD is also comfortable with innovation.

Its aero offering, for example, eschews current wider-and-blunter fashions from the competition. Instead FFWD has its proprietary DARC (AKA Double-Arc technology) design, with the rim being shaped with a slightly ‘waisted’ airfoil shape. The claim is that this creates a negative pressure section, which in turn compresses the airflow over the positive, increasing pressure and increasing airflow speed.

FFWD also claims that this makes for a stiffer structure and therefore a better-handling wheel.

Crash landings

Busying away in one corner of the shop floor is the service department, where we see a range of well-hammered wheels being cleaned, stripped, serviced and repaired.

"Service is a big part of what we are, so if your wheels need a new set of bearings, a replacement spoke or something more major as the result of a crash we aim to have them back in your possession in around a week and ready to be used – no-one wants to be without their best wheels for too long,” Timmerman explains. “We don’t think you can do this if you don’t handle all of the production of your wheels in house.”

FFWD's service department aims to get your freshly pampered wheels back to you within a week

But what happens if a wheel is beyond repair, say after a bad crash?

“If you’re unlucky [enough] to crash your wheel and it’s not a warranty issue then we offer a replacement service where you'll only be charged for the cost price of the components – we won’t charge for the assembly or distributing back, so it’s a significantly lower price.”

On the subject of crashing, Timmerman shows us the wheel used by Jonny Hoogerland on the fateful day is was struck by a TV car and punted into a painful meeting with barbed wire at the 2011 Tour de France.

Look over the rim and it looks pretty much together; you can, though, see where the car made contact and ripped plenty of spokes from their housing (in fact most of the brass nipples have been sheared clean in half). The spoke holes on the rim are a little wider, but you would think the wheel could be ridden.

“You can see where our structural reinforcement in the spoke beds has paid off,” Timmerman says. “Although the accident was horrible, we are somewhat proud of how well the rim stood up – you can’t get a better advertisement for our handmade qualities.”

Jonny Hoogerland's wheel is surpsingly intact after his horrendous crash in the 2011 TdF

While rim design and the construction of the wheels is down to FFWD, the brand turned to DT Swiss for hubs and spokes (along with Sapim CX-Rays).

“We don’t see the point in developing our own hubs,” de Jager explains. “DT work very closely with us and their 180, and 240 hubs are super reliable and easy to service and maintain. We also use DT for our entry level FFWD hub, and we have a project with them at the minute so we can introduce a straight-pull design into our lines.”

All in all, it's an interesting and illuminating day out at Zwolle. The small dedicated team all appear to be working to the same goal, the top brass in the office help out with loading boxes of finished wheels halfway through our visit, and we see Roman the master wheel builder giving the service department a hand too. (That’s aside from his development work, prototyping, process design and of course training the junior wheel builders.)

With the ‘handmade’ tag being so easily banded around in the bike world, it's nice to see that FFWD’s ‘Handmade in Holland’ tag isn’t just an empty promise, but the core around which the firm seems to want to build the success of its wheel business.