Last year, Donn Kellogg licensed the Clément name and resurrected the brand from its dormancy with the PDX and LAS clincher cyclo-cross tires. This season Clément will offer the tires in UCI-legal 33mm tubular versions, and add a variable/all conditions tire called MXP.

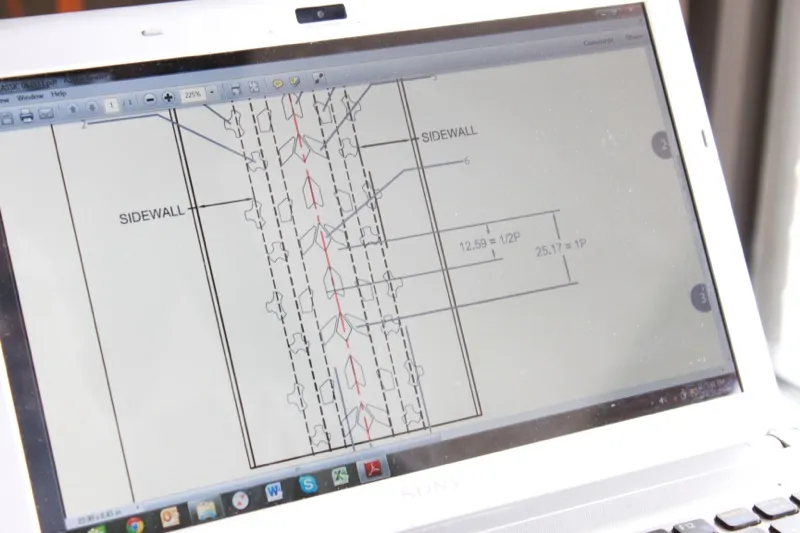

This new tread, which is an adapted version of the original Clément Grifo and still only in digital blueprint, is once again named after an airport code. While Clément's first two new tires were named after US cyclo-cross strongholds – the PDX mud tire gets its name from notoriously wet Portland, Oregon, while the file-tread LAS is named after hot and dry Las Vegas, Nevada – MXP is the code for Milan Malpensa Airport in Varese, Italy.

Kellogg, president of Donnely Sports, picked the name as a homage to the French brand's Italian pedigree – Italians bought the brand after World War I and Pirelli have owned it since the 1980s — and due to the fact that the Milan World Cup course generally calls for a mixed-conditions tire.

"We took the center knob [of the Grifo] and split it, so when it hits the ground it still acts like one, but it's more supple; it's not one big block going across the tread," Kellogg told BikeRadar. "Then we modified the side knobs; this is actually a knob we took off of a mountain bike design that we have. And the side knobs are the derivative from a soccer cleat, that's where the inspiration comes from."

The MXP all-condition design

PDX tubular

The US$129.99 PDX 33mm is nearly perfect on paper. It's light, built extraordinarily straight and true to what Clément calls 'best tolerances', and it has pre-coated sidewalls. The base tape is also said to be better adhered to the casing and offer multiple remounts without separation or tearing. Besides being pre-coated, the casing is 'tubeless' and built to work with a special sealant, making it more repairable than other tires.

Anyone who's familiar with cyclo-cross tubulars will recognize the trademark vulcanized tread and unique sidewall aesthetic of the casing as the work of Czech tire makers Tufo, which they are – with Clément still in the infancy of its latest rebirth, Kellogg wasn't in a situation to set up his own factory, so he decided to partner with Tufo to build his brand's tubular tires. However, Clément claim the casing to be an ultra-supple design that has never before been used.

The tread is vulcanized to the casing

The reason for the true-ness of the tire is that Tufo put the un-stitched section of the tire casing under the tread, instead of under the base tape as every other tubular maker does. This means the casing can't be opened, but making the tire tubeless negates any need for that.

The PDX is the first of Clément 's tubulars to roll off of the Tufo production line for this fall and should be available now. The LAS, with its unique progressive file tread (the size of the diamond tread grows as it gets further from the centerline) is projected to be available later this month September. And the MXP all-conditions tire is promised in October.

Handmade tubulars? No, but meant to compete with them

Tire manufacturers face a number of difficulties when looking to produce new cyclo-cross tubular tires: they've got to break through the hype of handmade tires, match their performance, and better their durability; tubular tires take resources to develop, but don't offer a huge market to recoup costs; finally, they've got to work better than what's out there.

Kellogg's aim was to offer better durability than the handmade manufacturers Challenge, Dugast and FMB. "To me handmade brings you down a certain path," he said. "280, 320tpi double layer of the casing – it's a completely different manufacturing process – and ultimately hand gluing the tread onto the tire... which is a cold vulcanizing process. Those are the attributes of 'handmade' versus our process, which is a manufacturing process and more of an extrusion than multiple steps of 'hand' building. We know that because of the process, the tread is straight on the casing and the tolerance, both side-to-side and up-and-down, is correct."

He also wanted the tires to be finished at the factory – meaning he didn't want riders to have to seal the tires after they'd bought them. "Pre-coating the sidewalls was a big thing for me," said Kellogg. "The coatings are toxic. If you could see the respirator I wear when I seal tires [you'd understand how seriously I take it]... that stuff is nasty."

Clément hope their new tubulars compete with the likes of Challenge, Dugast and FMB

Benefits of a known manufacturer, but without the cost

Past experience with Tufo tires backs up the majority of Kellogg's claims – they're very light, true to shape and some of the most durable on the market (although, of course, a slash or a large nail can still fell them in one swoop).

The main problem we've encountered with Tufo's own tubular models is their price – they're generally the most expensive available, due to their distribution channels, costing upwards of $150 a tire in the US.

Clément 's versions are all slated at $129.99, which still puts them among the most expensive, but at least not head and shoulders above them. Cost aside, the proven performance of the PDX and LAS clinchers gives good reason to give Clément 's tubulars a chance this season.