When we were invited by the fledgling Swift Carbon brand to visit their production facility in Xiamen, China, we leapt at the chance. This was a rare and very interesting opportunity to see the real core of the bike industry.

The big, prestigious American and European brands are only too happy to show off their impressive design centres and R&D facilities close to their headquarters but only their top-end frames, if any at all, are still made there. Public perception of the ‘made in China’ tag is still such that none of those famous names is throwing open the doors to their Asian factories just yet.

However, chances are your bike was made in the Far East, and by a factory that works for multiple brands. Underlining the relevance of this particular tour, not to mention giving great credibility to Swift, the facility visited by BikeRadar builds for several major European brands.

As a young brand, in their fifth year and new to the UK in 2012, Swift Carbon don’t have to worry about a history of making bikes in Tuscany or California. This is a thoroughly modern and international brand with technology, performance and value at its core.

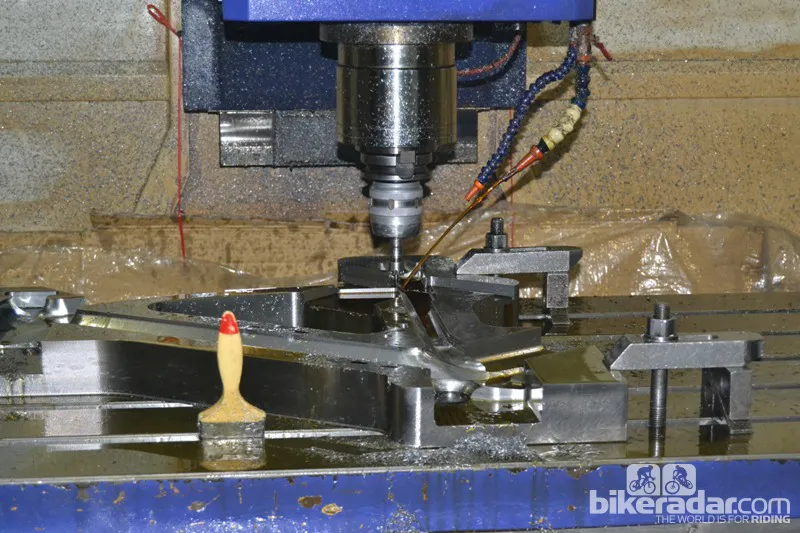

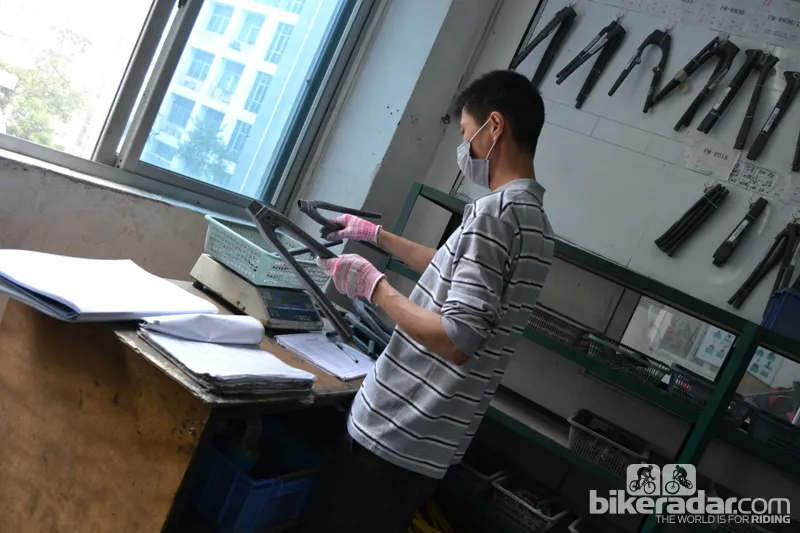

Founder Mark Blewett, a South African former pro racer on the European scene in the 1990s, understands that Asia is now the real centre of the industry so rather than simply task a Chinese factory to build his bikes, he's based himself and his company right here to capitalise on the expertise that’s focused in the region. It allows him to keep a close eye on quality control and speed up product development by testing prototypes himself in the surrounding hills when the carbon has barely cooled from the curing oven.

Xiamen is a sprawling, booming industrial city on China’s south coast, close to Taiwan. Its port is one of China’s main export points and the greater city area includes thousands of factories and a population of 3.5 million people. The centre looks much like Hong Kong – packed with neon-lit skyscrapers and dripping in new money – but just 5km from the last of the factories lies a huge expanse of steep hills with twisting roads through the forests and farmland – ideal bike testing terrain.

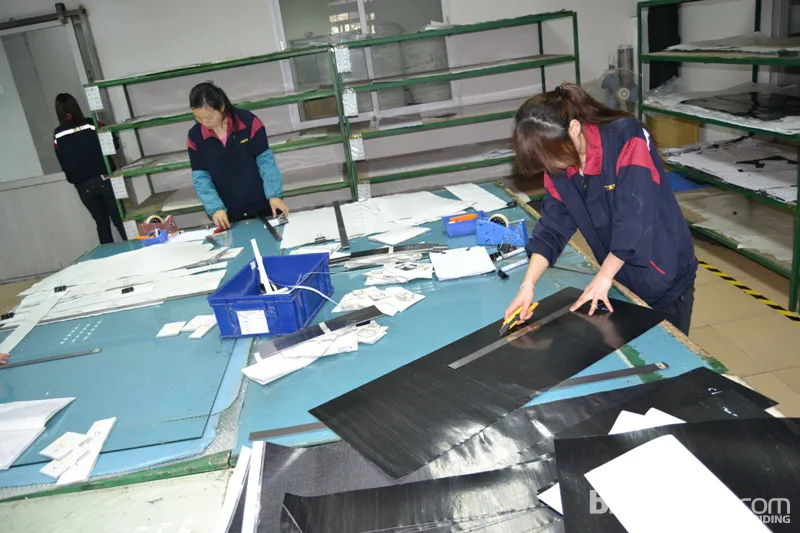

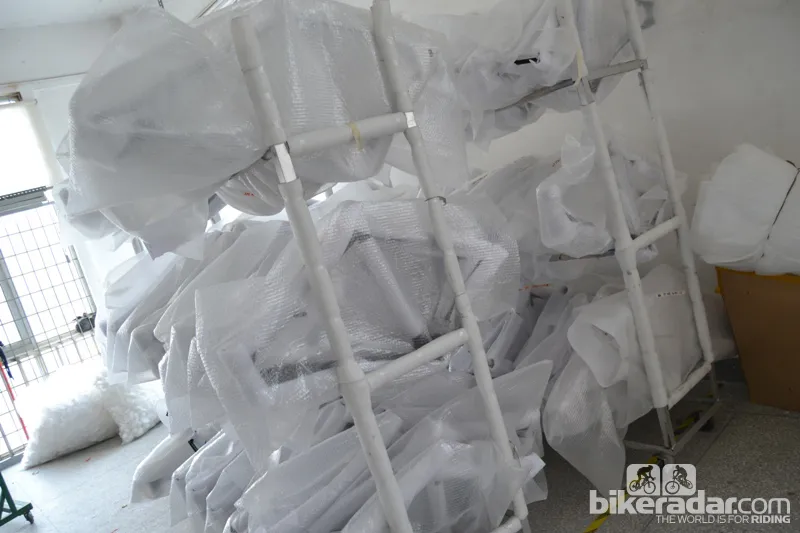

Check out our image gallery for a tour of the Swift Carbon factory.