Bearings are a very small part of your bike, but play one of the biggest roles in terms of its performance. It may be easy to dismiss bearings simply as little metal balls, but the truth is: bearings have developed to be as innovative as have frames, forks, and virtually every other part of the bicycle.

So whilst composites have changed the way frames evolve, space age materials have also changed the bearings we use today.

“How well the bearing performs is crucial,” Paul Humphreys, global marketing manager for bicycles from Saint-Gobain told BikeRadar, adding that the company’s bearings have been developed mainly for the automotive industry, but many of their ‘techiest’ bearings are making their way to bicycles.

The Saint-Gobain NorGlide bearings utilize composite materials, which Humphreys added “offer weight and performance improvement.” The development of the bearings is focused on a handful of benefits, including being “maintenance free, self-lubricating, reduced noise, reduction to vibration, resistance to stickiness and resistance to corrosion.”

These are far more than just little round metal balls, the new composite bearings can also be made in different shapes based on the customer and, or component needs. These could be a bearing with a flange, a top hat bearing, a cup or semi-shape bearing. And Saint-Gobain isn’t alone in supplying what the customer might need, and providing a product that will last and last.

“Bearing quality is something that is very easy for even the most discerning rider to overlook,” said Jim Morrison, headset guru and design engineer at Cane Creek Cycling Components, who make their AER headset with a NorGlide bearing. “After all, the only thing you're asking for is something that turns.”

He said that on the show-room floor the difference between a US$1 headset and a $150 headset pretty much comes down to looks, where the $150 models looks pretty sweet, but it probably won’t steer too much better than the $1 "black and round" model — initially.

“Riders don’t notice a bearing until it gives a problem,” said Humphreys.

“The difference in bearing quality really only comes over time and use,” Morrison told BikeRadar. “The $1 headset will last a few rides but will quickly become noisy due to contamination and rust. Over time, the bearing will turn less and less smoothly to the point that the rider will actually be able to feel roughness in the steering. The softness of [the bearings and races in] these low-end headsets also makes them very vulnerable to impact damage. Large hits can actually cause the balls to dent the races and will create a ‘preferred orientation’ of the handlebars which will make pace lines and no-hands riding pretty tough.”

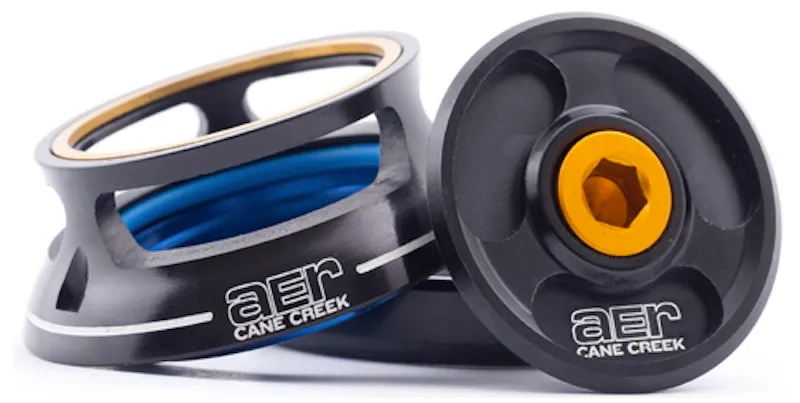

Cane Creek's NorGlide equipped AER headset

Thus he says a top-quality headset will feel like it did on the showroom floor for years and years. “And really that’s the point,” said Morrison. “We don’t want our headsets, or any other bearing to do much more than turn, but we’d like to have them turn smoothly and efficiently for a very long time without excessive maintenance. I consider my job done if you never have to think about your headset after you buy it.”

But do materials really matter? They do if you don’t want to think about it, say these bearing experts.

David Turner of Turner Bikes said his company uses IGUS journal bearings, which are made of solid composites. “I have always used IGUS and have great life span with them so I find it hard to switch," said Turner. "Riders in the UK are known to say, ‘when Turner Bike pivots are worn in, others are worn out.’ It is hard to switch with results like that.”

Turner's use a non-traditional bearing for their pivots, including the 5.Spot trail bike

Turner told BikeRadar that he has used the same bearing bores and pivot shafts for 18 years, adding that to discerning customers quality has long been appreciated. “Bearings have been cheaper, but superior life has nothing to do with marketing or customer perception.”

So if it isn’t marketing or customer perception, why change? It could just come back to weight and performance. “Probably the most obvious advantage to plain bearing is weight, or rather the lack thereof,” said Morrison. “Any time you can substitute a plain bearing for a rolling bearing you replace a big hunk of steel with other lighter materials such as aluminum and engineered polymers.”

He says that trying to predict the future is always difficult, but he believe that in the continued quest to wring more performance out of lighter bikes we will begin to see the reintroduction of bushings into various bicycle components. “For various reasons the term ‘bushing’ got a bad wrap in the bicycle industry about 10 years ago so I prefer to use the term generic ‘plain bearing’ or the more specific ‘polymer bearing’ or even ‘composite bearing,’” said Morrison. “That said, plain bearings offer many advantages over rolling bearings,” said Morrison.

He added that the other, less obvious advantage is that for a given size, plain bearings are far stronger than rolling bearings. Whilst it may at first seem counter intuitive because w steel is strong and plastic is flimsy, Morrison maintains that the same way that a wooden baseball bat is stronger than a steel sewing needle, size matters.

“The Achilles-heel of all rolling bearings is that they must transmit loads through small areas,” said Morrison. “If we take the example of a perfect sphere on a perfect plane, these two ideal objects only touch at one infinitely small point, we call this point contact. Similarly, if we look at a perfect cylinder rolling on the same plane the two objects now touch all along the length of the cylinder creating a ‘line contact.” While this line of contact has length, geometrically speaking it has no thickness.

Norco uses NorGlide bearings for the pivots in some of their full suspension bikes

The last big advantage of plain bearings is that they can be very resistant to contamination. Most bushing materials are inherently corrosion resistant and since the two surfaces are in full contact with one another, there is little room for dirt or water to enter into the function area of the bearing.

This is where Morrison says that the Saint-Gobain Norglide system has its advantages as well.

“In the case of our AER headset, the NorGlide bearing material that we use is aluminum, which oxidizes in a favorable manner, lined with PTFE which is inert so corrosion is really not a problem,” said Morrison. “In addition, the NorGlide material has a relatively thick PTFE layer which can actually absorb and coat any particulate matter that may come between the two bearing surfaces and thus will prevent damage to the bearing.

"Rolling bearings by contrast are made of steel which can rust and even the stainless steels used in bearing construction are not all that corrosion resistant. Rolling bearings are also very susceptible to particle contamination that can damage the raceways and rolling elements.”

And for Paul Humphreys this all means a better ride for the end user. “The materials offer the riders real benefit with weight. Every year customers are choosing NorGlide to save weight. And there are those other benefits, such as the low friction so parts move smoothly and best of all they are really maintenance free.”