Bearings are often-overlooked components that bring life to your bicycle. You can’t steer, roll, pedal or have a functioning drivetrain without bearings.

Bearings are found in your hubs, bottom bracket, headset, suspension pivots, pedals, shifters… the list goes on.

Basically, anything that moves on your bike will have some kind of bearing in it.

In this guide, we'll go over the different types of bearings commonly used on a bike, how to measure the bearings on your bike, what makes one bearing better than another and how to maintain bearings.

The different types of bearings used on a bike

Loose ball, caged ball, bushings, needle and cartridge are the main styles of bearing found in cycling frames and components.

Here, we explain how each type of bearing differs from the others.

Bushings

A bushing (also known as a bush, or sleeve bearing) is a type of plain bearing used in shock mounts, cheaper pulley wheels and shifters. They're also sometimes used in pedals, but usually in conjunction with bearings too.

A bushing is the simplest type of bearing and is just a sleeve that sits between two surfaces to reduce friction.

Loose ball bearings (also known as 'cup and cone' bearings)

A loose ball bearing system comprises:

- Loose ball bearings

- A cup that the bearings sit in

- A cone, which applies preload to the bearings

The contact surfaces of the cup and cone are machined to a smooth finish that matches the profile of the bearings, and this is what they run between.

Loose ball bearings are used commonly everywhere on entry-level bikes, including hubs, bottom brackets and headsets.

At the higher end, most brands have moved away from loose ball bearings, although Shimano and Campagnolo are notable holdouts. Both use very high-quality cup and cone bearings in most of their hubs. Shimano also uses loose bearings in its pedals.

Although they’re the oldest, in many ways they can be superior.

Loose ball bearings are angular contact (more on this later), relatively easy to maintain and can perform exceptionally if well-adjusted.

Loose ball bearings are sometimes held within a retainer, which is also known as a cage (hence the name 'caged bearings').

This is usually made from pressed steel and holds the loose ball bearings apart from one another.

Though often associated with the low end, caged bearings aren't universally bad – Campagnolo's CULT bearings, which exhibit excellent performance characteristics, are caged bearings.

Cane Creek's Hellbender Neo bearings are another interesting take on the concept.

Cartridge bearings

Cartridge bearings are the most common type of bearing used on anything but the very cheapest bikes.

These are a one-piece unit that is, usually, pressed into a bearing bore.

A typical radial cartridge bearing is made up of:

- Outer ring

- Outer ring ball race

- Ball bearings

- A cage/retainer to hold the bearings in place

- Inner ring ball race

- Inner ring

Cartridge bearings used on bikes will almost always feature seals too. They will be either single or double sealed (more on that later).

Though the seals can be removed for cleaning and regreasing, these bearings cannot be adjusted or fully disassembled.

Cartridge systems require precision to function well but, as manufacturing technology has moved on, they have become increasingly used as a result of ever-closer tolerances in hub, frame and component bores.

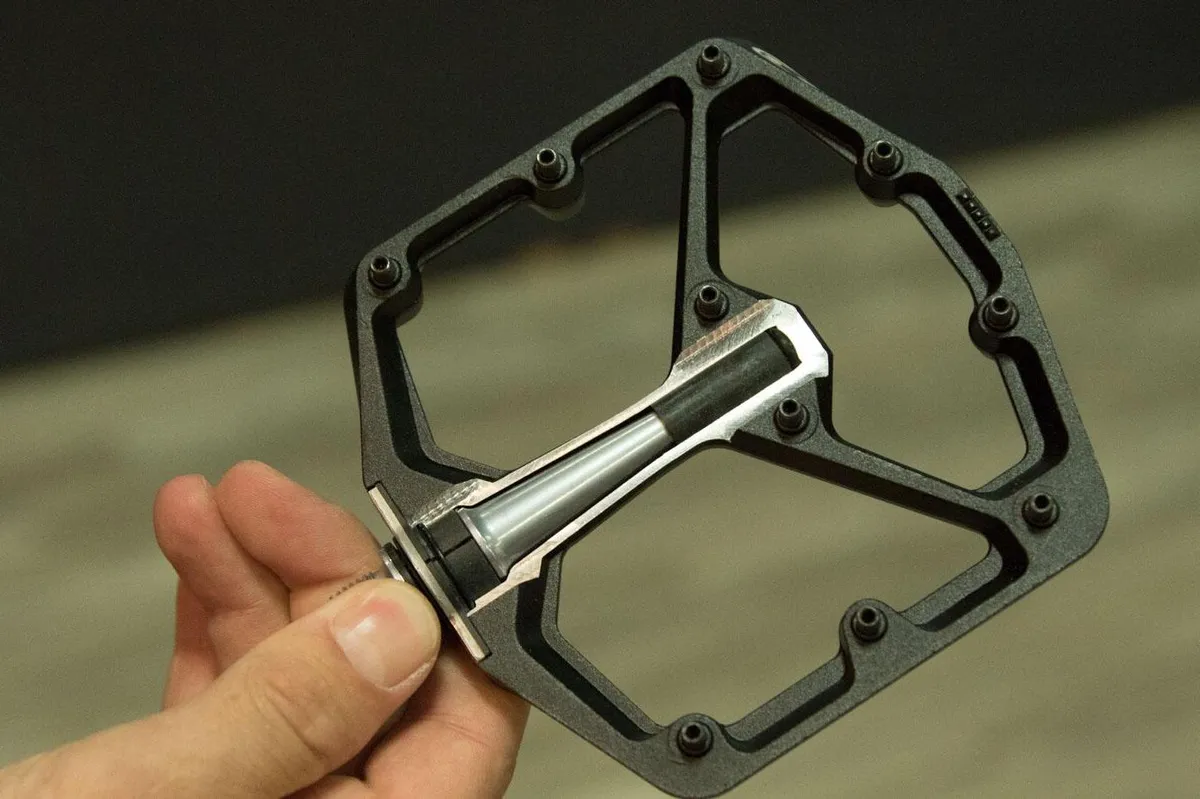

Needle bearings

Needle bearings, which are also known as roller bearings, are relatively uncommon in the cycling world.

The exception is pedals and, very occasionally in headsets, but even then they’ve lost a lot of ground to newer and cheaper tech.

In a needle bearing, instead of ball bearings, the bearings themselves are cylindrical tubes.

They can create incredibly smooth-rolling and stable platforms, especially under high loads.

However, in the cycling industry, there’s a tendency to shy away from them due to the expense and complication of creating good mating surfaces. When not mated properly, they tend to fatigue quickly.

Needle bearings often get replaced by multiple rows of cartridge bearings to achieve the same effect.

Bike bearing sizes explained

Loose ball bearing sizes

Loose ball-bearing sizes are determined by the diameter of the ball bearing itself. This is usually expressed as a fraction of an inch: 3/16in (4.7625 mm).

The exact size of bearing required will differ between individual components.

It is usually possible to replace the cone in a loose ball-bearing setup, but the cups (particularly in hubs) are less commonly replaceable.

If you need to replace the ball bearings in a cup and cone bearing, you'll need to make sure the new bearings are the same diameter as the old ones.

To do this accurately, you'll need a set of micrometer calipers. Measure a couple of your old ball bearings to make sure you've got it right.

Park Tool and other brands also produce rulers with helpful go/no-go gauges for common bearing sizes.

Alternatively, you should be able to find the specified ball-bearing size in the part manufacturer's tech guides on its site. Brands using loose bearings tend to stick to the same set of sizes across their ranges.

Cartridge bearing sizes

A cartridge bearing's size is determined by its inside diameter (ID), outside diameter (OD) and width.

The measurements take the form of ‘15x24x5mm’ or similar.

They often have a corresponding universal identifier, which in the case of the aforementioned bearing, would be 6802, for instance.

With calipers, you can measure a cartridge, enabling you to find a replacement quite easily.

Headsets pose a unique characteristic in that they have angled races. Their sizing might read more like ‘46.9 x 7 x 45°’ to identify the OD, width and angular measurements of the bearing race, respectively.

In regards to performance, generally speaking, the bigger the ball inside the bearing, the better.

Increasing diameter has an exponential factor for increasing contact. More contact means more even distribution of forces, and results in better rolling performance and durability.

Several major wheel manufacturers have pushed towards larger bearings in recent years and there are ever-increasing hub dimensions to show.

Radial vs angular cartridge

Two types of cartridge bearings are commonly used in bikes: radial and angular contact.

Radial bearings

Radial bearings are the most common, because they are cheaper.

They're intended to carry the load in a truly radial direction, which is vertical in terms of hubs, cranks, suspension pivots or derailleur pulleys.

Thus they sacrifice a small amount of performance because forces within these moving parts usually have a non-radial vector associated. As a result, they have to compensate with decreased tolerances.

In short, there’s less precision associated with radial cartridge systems. As such, they don’t have any directional application – there is no inside or outside.

As a benefit, because they are slightly less tolerance-dependent, they can be used in applications that aren’t quite as expensive.

Angular contact bearings

Angular contact bearings require tight tolerances because they are directional. There is an inside and outside component, and they can be compared to the old-style cup-and-cone systems in terms of design.

They support both the radial and side-force loads exerted with the rotating components of a bike, but require extreme tolerances in mating bores to accomplish a precise fit and rolling performance.

For the most part, angular contact is the most appropriate application for hubs, cranks and suspension.

However, many hubs and frames don’t possess mating bores of sufficient tolerances to complement the precision of the angular cartridge.

This precision is where brands such as Industry Nine, Chris King, White Industries, Phil Wood and Alchemy Wheel Works get their reputation.

What makes a bearing high-quality?

You will commonly see bearings referred to as 'ABEC' followed by a number (Eg, ABEC 1, 3, 5, 7 and 9).

The ABEC standard qualifies:

- Bore diameter – an acceptable variation of the size of the inner bearing hole

- Parallelism – width variation

- Radial raceway run-out – variations in the groove in which the balls sit

In brief, the higher the number, the higher the quality of the bearing. It serves as a rough 'good, better, best sort' of metric.

However, the ABEC system forgoes load handling, ball precision or Rockwell Hardness (material hardness).

As a general rule, ABEC 3 and 5 are appropriate for all things bicycle.

As for the 7 and 9 ratings, that level of precision is for equipment that sees rotations in the thousands or hundreds of thousands per minute – a touch of overkill for cycling.

Factors such as sealing, material and grease are far more important determinants of a bearing's performance on a bike.

A quick guide to seals

Cartridge bearings are usually sealed with two rubber seals on either face of the bearing.

It may sound like a dry and boring topic (pun intended), but they have a big bearing (eyyy) on the overall performance of a bearing.

There are three major considerations regarding seals – friction, protection and serviceability.

Friction is a major point of contention for cartridge bearings, and while less is better, a little friction can be an indication of protection.

The job of the seal is just that – to keep grease in and contaminants out.

But once you have contamination, can you clean and service your cartridge without damaging the seal?

For most quality bearings, including every bearing Enduro Bearings makes, the brand assures “with a small blade and a careful hand, seals can be removed from the inside race for servicing".

What types of seals are there on bicycle bearings?

Bearings on bicycles may be single-sealed, double-sealed or labyrinth-sealed.

A single seal is, as it suggests, a simple cover that clips into the outer edge of the bearing race. Since there's only one seal, it may be more prone to contamination than more sophisticated sealing.

A double-sealed bearing has a second sealing dust cover outside the primary seal and so the bearing should be less prone to contamination.

A labyrinth seal provides a convoluted path to help prevent the ingress of dirt and water into the bearing.

Its design may help to eject any contamination before it finds its way into the bearing itself.

Although a labyrinth seal should prolong the time between services, it may also add extra friction over a simpler sealing system.

What are bearings made from?

Bearings are made from a huge range of materials. Some examples include chromium steel, 440C stainless steel, XD15 super nitrogen stainless, and silicone nitride (ceramic bearings).

Generally speaking, the harder the material the better, but there is a point of diminishing returns.

Ultimately, too hard means the balls can become brittle, which is no better than too soft. There may also be differential wear between a hard ball bearing and the bearing race in which it sits.

Balancing the application of the bearing (hub, crank, suspension pivot, etc), how much service you’re willing to put in, and picking a budget are all considerations brands have to make when speccing bearings.

What are the benefits of ceramic bearings?

Ceramic bearings are up to five times harder than steel bearings, so they roll with less friction – and we all love less friction in our bikes.

They're also manufactured to closer tolerances, with the balls in the bearings more spherical than steel and require less and lighter lubricant, which again reduces friction in the bearing assembly.

According to Hunt Wheels, swapping steel for ceramic bearings across your hubs and drivetrain could save you between 6 and 9 watts.

On the other hand, ceramic bearings may need to be serviced more regularly than steel bearings. Industry experts agree that good-quality steel bearings can perform better than poor-quality ceramic ones.

Read our detailed article where we ask three experts whether ceramic bearings are worth the cost for more.

How to maintain bearings

Like any moving part on your bike, bearings require servicing. Maintenance intervals may be longer on higher-quality bearings, but no one bearing is truly 'fit and forget'.

Bearing servicing usually requires removing the bearing from your bike and using degreaser to remove the old lubricant.

At this stage, you can check for wear to the balls and bearing races. If either show wear or pitting, the bearing may need to be replaced.

You can then relubricate your bearing and reassemble it or, alternatively, replace a cartridge bearing or the balls in a loose bearing.

Proper installation plays a big part in bearing longevity too.

For loose bearings, ensuring that the cup and cone are tight enough that there's no play, but loose enough that the component spins efficiently can be tricky and you may need to adjust several times to get this right.

It may seem simple enough, but misalignment from improper installs of cartridge bearings is a big cause of premature wear. A professional bearing press will ensure that your bearing is installed correctly.

Also, if you’re working with angular contact bearings, the seals are different colours for a reason – black seals are meant to face the centreline, while red should face outwards.

Proper bearing maintenance ends with proper lubrication, which could be anything from sticky waterproof grease to thin frictionless lube.

Consult the manufacturer's instructions or talk to a bike shop to confirm the type of lubricant needed.

The manufacturer will usually point you to its own-brand lubricants, but these are usually more expensive than the alternatives.

Depending on the application, the type of bearing system used, how often maintenance is done and the type of environmental exposure the system experiences will dictate the best lubricant.

For more info, check out our in-depth guide on how to service bearings.