The headset is a component fitted into the head tube of your bike that enables it to steer and holds your fork in place.

However, there are almost as many variants of headset as there are types of bike, and making sense of which headset your bike uses, how it works and how to buy a replacement one is not a simple task.

A headset usually comprises – but not always – a separate component that presses into the head tube of the bike. It sits between the crown of the fork and the bottom of the head tube, and the top of the head tube and the stem.

Here's our guide to help you get to grips with the humble headset.

What are the parts of a headset and how do they work?

There are a few different types of headset, but they all function in a similar way.

The two bearings at either end of the head tube are what make things work. Traditionally, these have been held in pressed 'cups', but modern bikes also see bearings fitted directly into the frame.

The cups (or integrated assembly) provide the interface that locates the bearings in the frame.

The fork steerer slides into these bearings.

A crown race at the base of the steerer mates with the bottom bearing.

The conical shape of the race is centred on the fork steerer. This means it is self-centring on the bearing and, when preload is applied, the angled shape ensures it supports both axial and lateral loads. A top race performs the corresponding duties for the upper bearing.

Almost all of the axial load experienced by the fork during riding will be carried by the lower bearing, because this is effectively sitting on top of the fork.

The top bearing carries only the axial load exerted by the preload that's applied to hold the fork in place securely.

Incidentally, the interface between bearing and fork is called the race (crown race and top race) because it originally acted as the raceway, with the bearing balls in the headset rolling directly on it.

However, describing this component as a race on modern bikes is, strictly speaking, incorrect.

The ubiquity of cartridge bearings (sealed units that contain all the rolling elements) means it should be more correctly defined as a 'seat' or 'mating surface'.

Because the cartridge bearing comes as a pre-assembled unit, the crown race doesn’t have to support the ball bearings, these are contained inside the bearing assembly itself.

Finally, preload must be applied to the bearings to ensure everything is secured and remains in place. The general rule is that preload should be enough to prevent any rocking or movement of the steerer tube, while still enabling the fork to rotate freely.

What type of headset do I have on my bike?

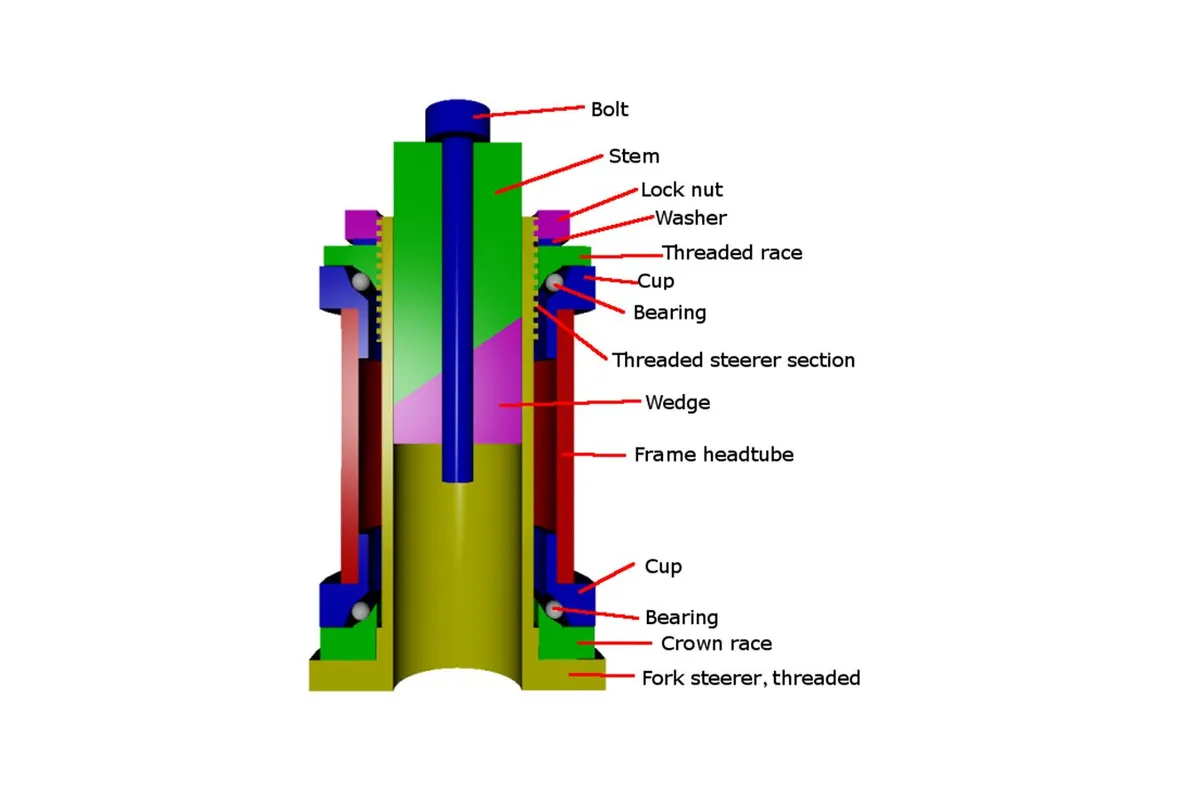

What is a threaded headset?

These days, you’re unlikely to find threaded headsets outside of budget bikes, some track and touring bikes, or on retro builds. However, given they were the standard for many years, they're still worth talking about.

On a threaded headset, the bearings sit in cups that are pressed into the top and bottom of the head tube. A race sits on the fork crown, completing the bearing assembly at the bottom of the head tube.

The steerer tube of the fork is threaded and a threaded race is screwed into the top of the fork to snug up against the top bearing.

The top race will generally incorporate a bearing cap with seals to shield the bearings from debris and the elements. Tightening this enables you to set the preload. This assembly is then secured with a locknut, holding the fork in place.

The stem – known as a quill stem – attaches separately, sliding inside the steerer tube. It is secured by tightening the top bolt, which engages an expanding wedge at its base to clamp the stem in place.

Depending on the length of the quill, you can adjust the height of the stem easily by sliding it further up or down inside the steerer and fixing it in the correct position.

However, the threaded design brings with it a few complications.

The fork must be matched precisely to the head tube length of the frame – it’s important that the steerer of the fork is just long enough to provide enough engagement for the threads of the locknut, without the locknut bottoming out on the top of the steerer.

The adjustment of a threaded headset also requires specific spanners sized to (the large dimensions of) the threaded race and locknut – not something you would necessarily want to take with you on rides.

Threaded headsets can sometimes have an annoying tendency to undo themselves due to a phenomenon known as precession. Regular care and maintenance can combat this, but still, it can be an issue.

Because threaded headsets comprise multiple overlapping components, they have increased weight over modern threadless designs, which are now more commonplace.

However, you’ll still get a few misty-eyed romantics lamenting the loss of the elegant lines of a threaded headset. As a result of this nostalgia, threaded headsets are going through a bit of a resurgence in the custom-bike market.

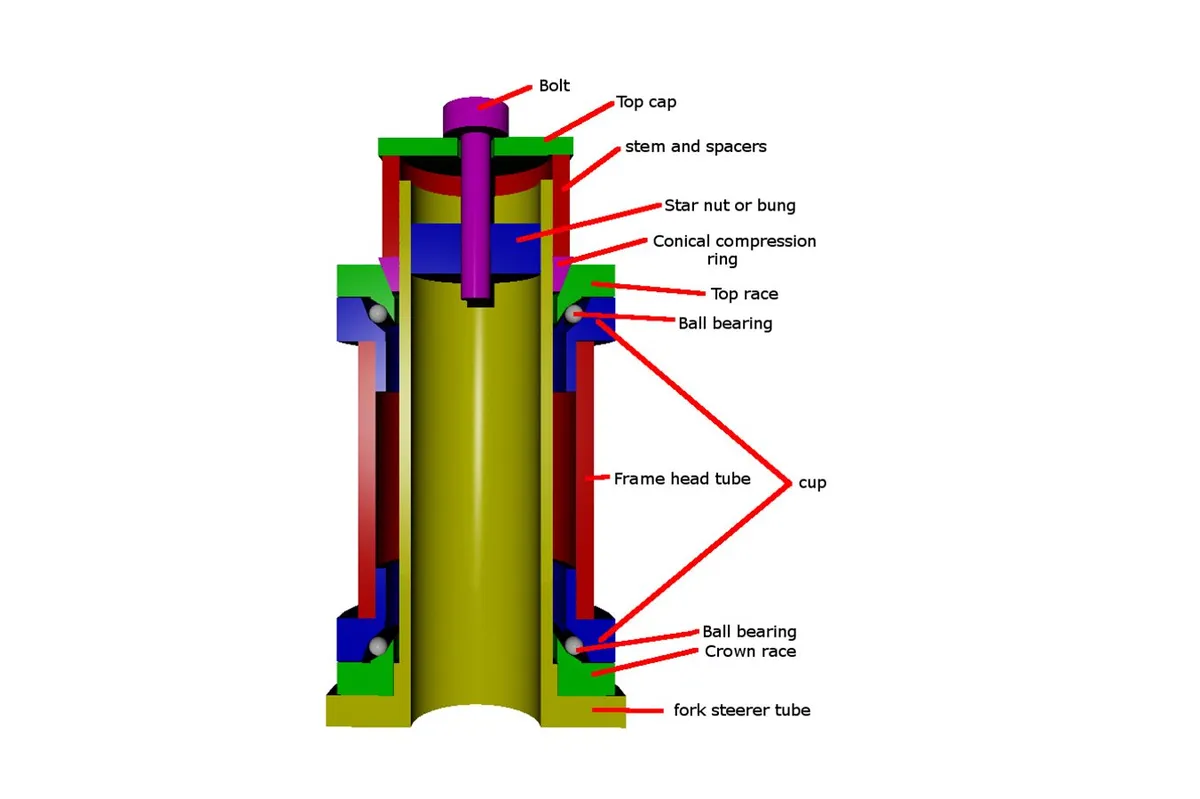

What is a threadless / A-headset?

The threadless headset is a much simpler and arguably superior design. It's quicker and easier to service, which can be done with standard tools – hex or Torx keys in most cases.

As with the threaded headset, bearings are fitted at the top and bottom of the head tube. A crown race sits at the bottom of the steerer tube and mates with the lower bearings.

But, unlike the threaded design, the fork is not captive to the headset and is only held in place by a stem clamped to the steerer extending through the head tube.

The stem is clamped to the outside of the steerer tube, and its height can be adjusted with spacers.

Before tightening the stem, preload must be applied through the top cap, with a bolt that ‘pulls’ on a star nut or bung fixed inside the steerer tube.

Star nuts are only really used with metal steerer tubes. The two rows of ‘star-shaped’ teeth are curved so they bend back when pressed into the steerer, but bite into place when a preload is applied, pulling against the direction of the teeth.

For carbon forks (with a carbon steerer), an expander (also known as a bung) is installed, which spreads the load across a wider area inside the steerer.

Expanders also mitigates against crush injuries of the carbon steerer, as they provide a ‘solid’ element to support the carbon when the stem is clamped in place.

The preload force is transmitted via the stem (and spacers), which sit slightly proud of the steerer tube at the top (around a 2–3mm gap is ideal), ‘pulling’ the steerer tube up, applying preload and seating the fork properly in the bearings.

The conical crown race locates the steerer with respect to the lower bearing at the base of the head tube.

The top bearing interfaces with a slotted conical compression ring. As preload is applied, the compression ring effectively gets wedged between the top bearing and the steerer tube, tightening around the steerer as preload is applied and the slot closes.

This secures the steerer tube with respect to the top bearing. Unlike the threaded steerer, where the threaded race provides a direct connection with the steerer tube, here the compression ring is required to take up any ‘slop’ between the steerer and the bearing.

On high-end headsets, the compression ring is often a captive element of the headset cap that sits on top of the headset to seal it from the elements. With preload applied, the stem can be tightened, clamping things in place.

Once the stem has been tightened, the top cap doesn’t serve any purpose. It's just there to apply the initial preload before the stem secures the whole assembly.

There are a few different types of threadless headset available, but they all follow the same basic assembly principle. The differences are mainly in how the bearings are fitted into the frame.

What is an external threadless headset?

This is the original threadless design. The bearings sit in external bearing cups, and the bearing cups are pressed into the top and bottom of the head tube.

The bearings are generally a transition fit inside the headset cups. That means that while they can still be removed by hand with some force, they sit snugly inside their seat.

The bearings generally have a conical interface with the cup, which helps secure and locate the bearing inside the cup when preload is applied.

Some manufacturers (such as Chris King) choose to press-fit the bearings inside the headset cups.

This improves the security of the bearing and prevents movement, but does mean the bearings can’t (officially) be removed for servicing and have to be cleaned and serviced in situ.

What is an internal / semi-integrated headset?

As above, the bearings sit in cups, but these, in turn, sit inside, rather than proud of, the head tube, with only a small lip protruding to locate the cup and prevent it being pressed all the way inside the head tube.

In order to accommodate the bearings inside the cup, the head tube has a larger overall diameter.

A side-effect of this is that larger diameter tubing can be used, resulting in increases in stiffness of the frame in this area.

What is an integrated headset?

An integrated headset does away with the bearing cups, with the bearings dropped into pre-shaped seats at either end of the head tube – the head tube takes over the duties of the bearing cups.

The bearings actually sit loose within these seats – they aren’t fitted with the press fit that you might expect from components, such as press-fit bottom brackets.

Instead, the head tube is bored with conical seats. When preload is applied, these angled seats result in the bearings self-aligning, as well as securing them in place, creating a rigid assembly.

It has been claimed this configuration is a cost-saving measure on behalf of manufacturers. Rather than pressing a bearing cup into the frame, the bearing can simply be dropped in during assembly.

It also appears to allow slightly more relaxed manufacturing tolerances, though it is critical the two bores are machined concentrically and on the same axis for good fitting of the headset.

The standard angle for the conical bore is 45 degrees. 36 degrees is now considered obsolete, but may occasionally be found on older frames.

In some cases, the seats may be machined out square with respect to the head tube and inserts can then be pressed in with the required contact angle.

Conceptually, the zero stack and integrated bearing arrangements could also be adapted to threaded headsets as well.

Mixing headset standards

Some head tubes use a mix of different designs, for example, an external cup at the bottom and a semi-integrated design at the top.

What is a crown race?

Apart from the interface with the frame, the headset must also interface with the steerer tube.

Forks have traditionally been fitted with a crown race near the crown of the fork. Originally, loose ball bearings were used for the headset, and this provided a hardened and precisely machined surface for the balls to roll on.

As mentioned, nowadays, with the common use of cartridge bearings, this part is strictly speaking a seat (given that the races are integral to the cartridge bearing). However, the term 'race' has carried over, in this case it means a surface for the bearing to mate with.

Crown races are often headset-specific, with many different variations of the precise dimensions and interface with the bearings. Therefore, if you are swapping a headset, you will probably need to swap the crown race on the fork.

Cartridge bearings also allow for split crown races to be used, easing installation. Because the crown race acts as a seat, it can be slotted without negative impact, allowing it to be opened up to loosen the fit when installing or removing it.

The use of cartridge bearings has also allowed for the development of integrated crown races. Because the load is spread by the outer seat of the bearing (rather than hard bearing balls rolling directly on the seat), softer materials, such as carbon fibre, can be used to construct the ‘race’.

An integrated crown race is simply a steerer tube that has been shaped to mate precisely with the outer race of the headset bearing. This takes over the duties of the crown race that would have been installed before.

Integrated crown races typically come in two different angles – 36 or 45 degrees.

What are the common steerer diameters?

The other key part to consider is the steerer diameter. The standard sizes are 1 inch, 1 1/8 inch, 1.25 inch and 1.5 inch steerers.

You may occasionally come across a 1-inch threadless steerer, but you’re more likely to find a threaded steerer in this size. 1 1/8-inch threaded steerers are, however, quite common.

Tapered steerer tubes are the most common arrangement on modern bikes. This attempts to provide the best of both worlds, with a wide crown that provides improved steering stiffness, with a tapered top section that saves a little weight. This is found on both mountain bikes and road bikes.

The corresponding shape of the head tube (known as a 'frustum' in engineering circles) also allows frame design to be optimised, with the larger lower section providing a larger surface area to connect with the down tube.

This enables designers to increase stiffness here, with the top tube kept relatively skinny to improve riding comfort and reduce weight.

SHIS Standards: ZS, IS, EC. What does it all mean?

There are plenty of options then.

Thankfully, there is a standard of sorts for headsets to help navigate you through the array of parts, and – moreover – the names of parts on the market.

If you're shopping around, you’ll notice different brands have different names for the same headset type.

The SHIS (Standardised Headset Identification System) describes headsets in a way that makes it easier to find what you need.

The identifier starts by describing the headset type with a two-letter code – 'EC' stands for external cup; 'ZS' for zero-stack/ internal headset; and 'IS' for integrated headset.

The number following the headset type denotes the head tube bore diameter (or bearing/cup outer diameter). The number is given in whole millimetres, but does not always correspond exactly to the dimensions of the bore.

It should be considered as a code for the different sizes, with each number uniquely identifying a head-tube diameter.

SHIS for external cup (EC) headsets

| Common name | SHIS name | Bore inside diameter (mm) | Cup outside diameter (mm) |

|---|---|---|---|

| 1 in JIS | EC29 | 29.85 – 29.9 | 30 – 30.1 |

| 1 in Pro | EC30 | 30.05 – 30.1 | 30.2 – 30.3 |

| 1 in BMX | EC33 | 32.6 – 32.7 | 32.8 – 32.9 |

| 1-1/8 in external | EC34 | 33.9 – 33.95 | 34.05 – 34.15 |

| 1-1/4 in external | EC37 | 36.9 – 36.95 | 37.05 – 37.15 |

| 1.5 in external | EC44 | 43.95 – 44 | 44.1 – 44.15 |

| 1.5 in external | EC49 | 49.57 – 49.61 | 49.7 – 49.75 |

| 1.5 in external | EC56 | 55.9 – 55.95 | 56 – 56.05 |

The bore depth for an external headset should be at least 15mm.

SHIS for semi-integrated/zero-stack (ZS) headsets

| Common name | SHIS name | Bore inside diameter (mm) | Cup outside diameter (mm) |

|---|---|---|---|

| 1 in semi-integrated | ZS41 | 41.35 – 41.4 | 41.45 – 41.5 |

| 1-1/8 in semi-integrated | ZS44 | 43.95 – 44 | 44.05 – 44.1 |

| 1-1/2 in semi-integrated | ZS49 | 49.57 – 49.61 | 49.7 - 49.75 |

| 1-1/2 in semi-integrated | ZS55 | 54.9 – 54.95 | 55.05 – 55.1 |

| 1-1/2 in semi-integrated | ZS56 | 55.9 – 55.95 | 56.05 – 56.1 |

The bore depth for a zero-stack headset should be at least 12.5mm.

SHIS for integrated (IS) headsets

| Common name | SHIS name | Bore inside diameter (mm) | Bearing outside diameter (mm) | Bore depth (mm) |

|---|---|---|---|---|

| 1 in IS (Cane Creek) | IS38 | 38.15 – 38.25 | 38 | 3.1 – 3.2 (top) / 6.9 – 7 (base) |

| 1-1/8 in IS (Cane Creek) | IS41 | 41.1 – 41.2 | 41 | 3.1 – 3.2 (top) / 6.9 – 7 (base) |

| 1-1/8 in Italian | IS42 | 41.95 – 42.05 | 41.8 | 2.8 – 3.0 (top) / 6.6 – 6.8 (base) |

| 1-1/4 in IS (lower only) | IS47 | 47 – 47.1 | 47 | 49.1 – 49.2 (base) |

| 1-3/8 in IS (lower only) | IS49 | 49.10 – 49.2 | 49 | 51.1 – 51.15 (base) |

| 1-1/2 in IS (lower only) | IS52 | 52.05 – 52.15 | 52 | 7.3–7.5 (base) |

SHIS terminology for integrated bearing refers to a 45-degree contact angle with the head tube. 36 degrees is now considered obsolete.

SHIS for the steerer

| Common name | SHIS name | Steerer diameter (mm) |

|---|---|---|

| 1 in French threaded | M25-1.0 | 25.0 |

| 1 in threaded (English, Italian, JIS, BMX etc.) | 25.4-24tpi | 25.4 |

| 1-1/8 in threaded | 28.6-26tpi | 28.6 |

| 1-1/4 in threaded | 31.8-26tpi | 31.8 |

| 1 in threadless | 25.4 | 25.4 |

| 1-1/8 in threadless | 28.6 | 28.6 |

| 1-1/4 in threadless | 31.8 | 31.8 |

| 1-1/2 in threadless | 38.1 | 38.1 |

The dimension of the headset is further defined by codes identifying the diameter of the fork steerer at the top and bottom of the head tube.

The upper section of the steerer is identified by its diameter, and in the case of threaded steerers by the thread used for that steerer.

SHIS for the crown race — common crown race standards

| Common name | SHIS name | Crown seat diameter (mm) |

|---|---|---|

| 1 in Pro | 26 | 26.43 – 26.49 |

| 1 in JIS | 27 | 27.03 – 27.09 |

| 1-1/8 in | 30 | 30.015 – 30.075 |

| 1-1/4 in | 33 | 33.03 – 33.09 |

| 1.5 in | 40 | 39.79 – 39.85 |

The lower section is identified by the diameter of the fork crown race, which is another number code corresponding approximately to the crown race inner diameter in mm.

| Common name | SHIS name |

|---|---|

| 1-1/8 in Cane Creek standard | 30 (36) |

| 1-1/8 in Italian standard | 30 (45) |

| 1-1/4 in | 34 (45) |

| 1-3/8 in Cane Creek standard | 37 (36) |

| 1-3/8 in Taiwan standard | 37 (45) |

| 1.5i n 36-degree | 40 (36) |

| 1.5 in 45-degree | 40 (45) |

All this can be combined to define the precise specification for the upper and lower bearings of the headset.The crown race angle may further be identified by an angle specified in brackets. This is particularly relevant for integrated crown races, where the angle is fixed at either 36 or 45 degrees.

As an example, a traditional 1-1/8in external threadless headset with a straight steerer would be defined as follows:

- The upper cup would be EC34 with a 28.6 steerer. This is written as EC34/28.6.

- The lower cup would also be EC34 but with a 30 crown race. This is written as EC34/30.

- These two codes are combined as EC34/28.6 | EC34/30 to fully define the upper and lower stack of the headset.

Headset manufacturers may also choose to specify the stack height for the upper and lower bearing stack by adding an 'H' followed by the stack height in millimetres.

In our experience, this measurement is unlikely to vary much between headset designs, and any differences are likely to be negligible.

Special and unusual headsets

Defining the SHIS code will tell you what kind of headset will fit the bike, but there are also some additional choices you can make.

Special-purpose headsets can significantly change your ride and are becoming more popular in mountain biking as a cheaper way to tune your geometry.

Angle headset / AngleSet

Popularised by Cane Creek under the AngleSet name, this headset enables you to tune a bike's head angle.

Instead of the steerer tube running vertically through the head tube, an angled headset makes use of the ‘spare space’ inside, to angle the steerer by up to 2 degrees.

Slackening the head angle in this way can lead to improvements in the handling of a mountain bike and doesn’t affect the seat angle and bottom-bracket height as it would with offset shock bushings

Reach-adjust headset

Similarly, a reach-adjust headset enables you to fine-tune the reach of a bike. Rather than adjust the angle of the steerer, the whole steerer is offset within the head tube.

ViscoSet

One interesting headset we’ve come across is Cane Creek’s ViscoSet. This offers damped steering, and BikeRadar's Jack Luke found it relaxed handling and stopped speed wobble on his tandem.

What makes a quality headset?

There is definitely a point of diminishing returns where investing more money in a headset isn’t going to buy you that much extra.

As you go up in price, the quality of the bearing increases and the level of sealing improves, but at a certain point, you don’t need to pay more for significant performance gains.

Some manufacturers offer overbuilt headsets for heavy-duty use, but even for mountain biking, we feel this is overkill. Suspension provides more than enough damping to reduce the forces going into the headset.

With that said, you should look for ample sealing, good availability of spare parts and, if it’s important to you, low weight.

All about bearings

Bearings come in two flavours.

In the past, loose balls were sometimes held in place in bearing cages. That has changed, with the majority of headsets now using cartridge bearings.

High-end cartridge bearings can also be serviced, but in many cases, it’s just as easy to swap them out for new ones. Because the bearing assembly in contained in one unit, it’s an easy drop-in replacement. Because the headset has to deal with complex loading, with force transmitted along the axis of the steerer as well as laterally, it should be fitted with angular contact bearings that are able to support load in both these directions.

How to maintain and fix a headset

If your headset feels gritty or horrible, it might be time to service your headset and/or replace your headset bearings.

At that point, take the fork out of the head tube and check the bearings. They may need replacing or cleaning and regreasing. It’s an easy enough job that doesn't require many tools.

You should also regularly check headsets for play, which could indicate wear or a loose headset. We recommend applying the front brake and rocking the bike back and forward while grappling the crown of the fork.

If there’s any play of the fork in the steerer tube, or any knocking or clunking noises, check the headset for tightness. If that doesn’t rectify the issue, some servicing is likely due.